- Intake manifold distributes air evenly to every cylinder for efficient combustion.

- It also aids cooling, flow optimization, and thermal stability through material choices.

- Air path includes filtration, MAF sensor, throttle, and temperature sensors feeding the ECU.

- Modern systems use variable-geometry runners and sensors to optimize performance.

Internal combustion engines remain the cornerstone of most modern cars, even as electrification accelerates. With a history spanning over a century, this technology continues to dominate road transport due to proven efficiency and reliability. Regardless of an engine’s performance, it cannot operate without one essential ingredient: clean air in sufficient quantity.

Air must reach every cylinder evenly, not by chance, but through a complex system centered on the intake manifold. This component, though often overlooked, plays a vital role in the engine’s performance and longevity.

The Essential Role of the Intake Manifold in Engine Operation

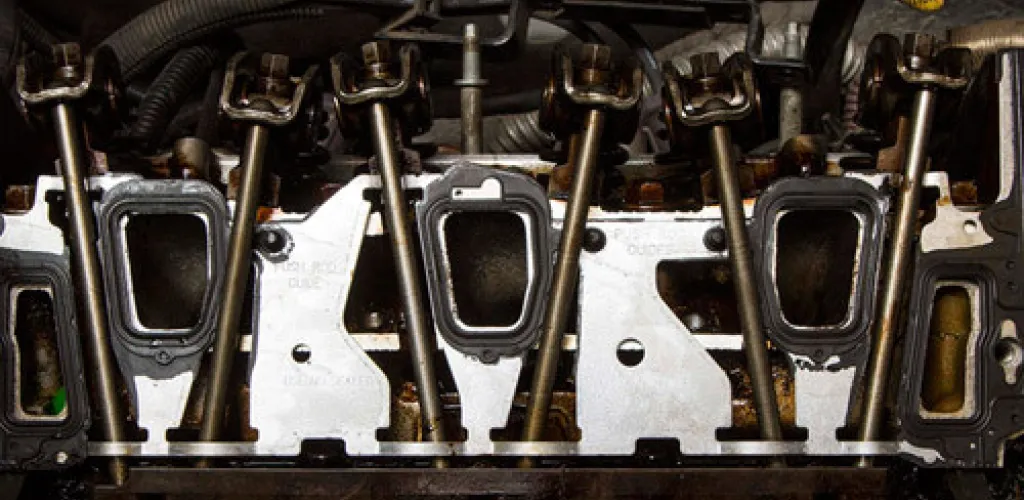

The intake manifold is an assembly of tubes and passages that distributes air evenly to each cylinder of the engine. Comparable to the human body’s respiratory system, the manifold ensures that every cylinder receives the optimal amount of air for the combustion process.

Without a constant and balanced air supply, fuel cannot burn efficiently, and the engine cannot develop the power required. This vital function applies to all types of internal combustion engines – gasoline, diesel, or hybrid systems.

Important Secondary Functions

In addition to air distribution, the intake manifold performs other crucial tasks:

- Engine cooling: Enables efficient circulation of the coolant through the engine block channels

- Flow optimization: Internal design influences air velocity and turbulence

- Thermal stability: Materials used (aluminum, stainless steel, cast iron or plastic) affect heat transfer

The Complex Air Path in the Intake System

The journey of air from the outside to the cylinders involves several critical stages, each with a specific role in optimizing the combustion process.

First Stage: Filtration

The process begins with the air filter, the engine’s first guardian. It removes dust particles, pollen, and other impurities through a specialized fiber made of paper or cotton. A clogged filter can significantly reduce engine performance.

Monitoring and Measurement

Air that has been filtered then passes through:

- Mass Air Flow (MAF) sensor – measures the volume of incoming air precisely

- Throttle plate – regulates the flow according to the driver’s command

- Temperature sensors – monitor air density

This information is transmitted in real time to the Engine Control Unit (ECU), which calculates the optimum amount of fuel required.

Final Distribution

In the intake manifold, air is distributed evenly to each cylinder. In turbocharged engines, the air is compressed before intake, increasing density and, consequently, the power produced.

Modern Technology: Intelligent Intake Systems

Modern intake systems incorporate advanced technologies to optimize performance across all operating regimes.

Variable-Geometry Runners

These systems alter the shape or length of the channels based on:

- Engine speed: Long channels for torque at low RPM, short channels for power at high RPM

- Engine load: Adaptation to momentary demands

- Operating conditions: Optimization for efficiency or performance

Advanced Electronic Control

The contemporary ECU manages the intake system through:

- Real-time throttle control

- Synchronization with the injection system

- Adaptation to data from multiple sensors

- Compensation for atmospheric conditions

Intake System Faults: Causes and Symptoms

Although not extremely common, intake manifold faults can seriously affect engine operation and lead to substantial repair costs.

Cracking of the Manifold

Counterintuitively, a crack in the intake manifold does not lead to a simple air loss; it causes uncontrolled air entry from the outside. This phenomenon disrupts the air–fuel mixture balance, resulting in a lean running condition (too much air, insufficient fuel).

Characteristic Symptoms

Early recognition of problems can prevent major damage:

- Power loss during acceleration, especially at low RPM

- Increased fuel consumption due to ECU compensation

- Check engine light on the dashboard

- Unstable idle and possible engine misfires

- Overheating and a drop in coolant level

- Squealing noise under the hood when accelerating

Quick Diagnostic Method

You can check for a possible leak by:

- Spraying starting fluid around the gasket area

- If the engine RPMs rise spontaneously, the gaskets are no longer sealing

- Visual inspection with an endoscope for internal cracks

Maintenance and Cleaning of the Intake Manifold

Especially on diesel engines equipped with the EGR system, the manifold can become clogged with soot and oily deposits that significantly affect performance.

Causes of Clogging

- Exhaust Gas Recirculation (EGR) introduces particulates into the intake system

- Fuel quality influences the amount of deposits

- Driving style – urban traffic increases deposits

- Improper maintenance of the air filter

Professional Cleaning Methods

Disassembly cleaning:

- Complete removal of the manifold

- Spraying specialized degreasing solutions

- Manual cleaning of the channels

- Checking all gaskets

Ultrasonic cleaning:

- More advanced and efficient

- Complete removal of deposits without risk of damage

- Penetrates all passages and corners

- Superior results compared to traditional methods

Associated Components for Replacement

During manifold cleaning, the following are recommended for replacement:

- All gaskets for optimal sealing

- Vacuum hoses that may be damaged

- Glow plugs for diesel engines

- Air filter to prevent recontamination

- MAF sensor if deposits are present

Prevention Tips

To reduce the need for frequent cleanings:

- Regular maintenance of the air filter

- Use of high-quality fuels with cleaning additives

- Periodic high-RPM highway driving

- Check the EGR system according to the service schedule

- Use specialized fuel additives

The Importance of Preventive Maintenance

An intake manifold in optimal condition is essential for:

- Consistent engine performance

- Reduced fuel consumption

- Lower NOx emissions

- Longevity of engine components

- Avoiding costly repairs

Preventive maintenance of the intake system is a small investment that can prevent major and costly problems in the long term.