- Four-stroke engine converts fuel energy through intake, compression, ignition, and expansion.

- Otto cycle for gasoline and Diesel cycle for diesel engines.

- Key components include piston, cylinder, intake and exhaust valves, crankshaft.

- Intake phase draws fuel-air mix with open intake valves and closed exhaust.

The four-stroke engine remains the cornerstone of most modern vehicles, a clever system that converts chemical energy from fuel into mechanical energy through four distinct phases. This operating cycle, also known as the Otto cycle for gasoline engines or the Diesel cycle for diesel engines, repeats continuously to deliver the power needed to move a vehicle.

Internal combustion engines are classified into two main categories: compression-ignition (diesel) and spark-ignition (gasoline). Both types rely on the same basic principle of the four-stroke cycle, with differences in how the fuel-air mixture is ignited.

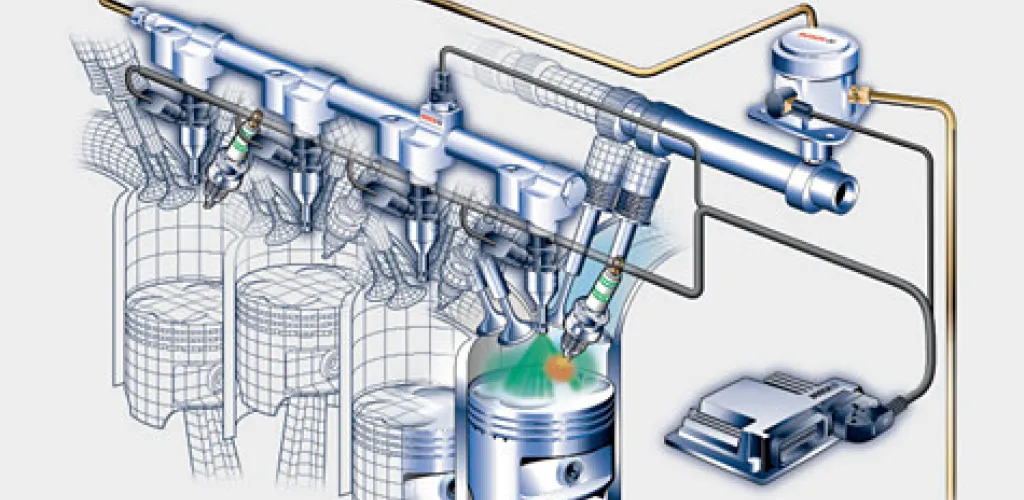

Structure and essential components

- Piston: the moving element that travels inside the cylinder

- Cylinder: the space where combustion occurs

- Intake and exhaust valves: control the entry and exit of fluids

- Crankshaft: converts the piston’s linear motion into rotational motion

- Spark plug (gasoline) or injector (diesel): ensures ignition of the fuel-air mixture

Time 1: Intake – introduction of the mixture

The piston moves downward toward the crankshaft, creating a partial vacuum in the cylinder that allows the intake of the fuel-air mixture. In this crucial phase:

- Intake valves are fully open

- Exhaust valves remain hermetically closed

- Gasoline engines: the fuel-air mixture is prepared in advance

- Diesel engines: clean air enters the cylinder only

The efficiency of this phase directly affects the engine’s final power. A faulty intake can significantly reduce vehicle performance.

Time 2: Compression – preparation for combustion

In this phase, both the exhaust and intake are closed, creating a completely sealed space. The piston begins to rise inside the cylinder, compressing the mixture to a fraction of its initial volume.

Key compression parameters

- Compression ratio: varies between 8:1–12:1 for gasoline and 14:1–23:1 for diesel

- Temperature rise: air heats up due to compression to 300–500°C

- Pressure: rises to 12–20 bar for gasoline and 30–55 bar for diesel

In diesel engines, the high temperatures from extreme compression are sufficient to auto-ignite the fuel injected in the next phase.

Time 3: Combustion and expansion – power generation

This is the moment when chemical energy is transformed into mechanical energy. The fuel-air mixture inside the cylinder is ignited:

- Gasoline engines: by the spark produced by spark plug

- Diesel engines: by auto-ignition due to the high temperature from compression

Combustion parameters

- Pressure: reaches 30–40 bar in gasoline and up to 150 bar in diesel

- Temperature: exceeds 2200°C, can reach 2500°C

- Duration: complete combustion lasts only a few milliseconds

Because of this immense pressure, the piston is forced downward inside the cylinder, transmitting the forces generated by the explosion to the crankshaft via the connecting rod.

Time 4: Exhaust – removal of burnt gases

In the final stage, the intake valve remains closed, and the exhaust valve opens to allow the gases produced by combustion to exit.

Important technical details

- The exhaust valve opens before the piston reaches bottom dead center

- This early opening ensures optimal removal of exhaust gases

- Exhaust gases have temperatures of 400–900°C

- Exhaust pressure varies between 1.2–1.8 bar

Synchronization and repetition of the cycle

The four strokes take place during two complete crankshaft revolutions (720 degrees). Perfect synchronization is ensured by:

- Camshaft: controls the opening and closing of the valves

- Timing system: belt or chain drive

- Flywheel: maintains inertia between cycles

At a engine running at 3000 rpm, this cycle repeats 1500 times per minute per cylinder, illustrating the extraordinary precision required for proper operation.

Efficiency and modern optimizations

Modern four-stroke engines benefit from numerous optimizations:

- Direct injection: improves combustion efficiency

- Turbocharging: increases power by boosting air density

- Variable valve timing: optimizes valve opening according to engine speed

- Exhaust gas recirculation (EGR) systems: reduce pollutant emissions

Understanding these four fundamental strokes provides a solid foundation for understanding the operation of any internal combustion engine, essential for automotive enthusiasts and those who want to understand the vehicle they drive.