- Throttle plate controls air intake and is driven by an ECU-controlled motor.

- Dirt, carbon buildup, vacuum leaks, and electrical issues affect idle and power.

- Common symptoms include unstable idle, erratic acceleration, and warning lights.

- Regular cleaning between the air filter and intake manifold helps prevent issues.

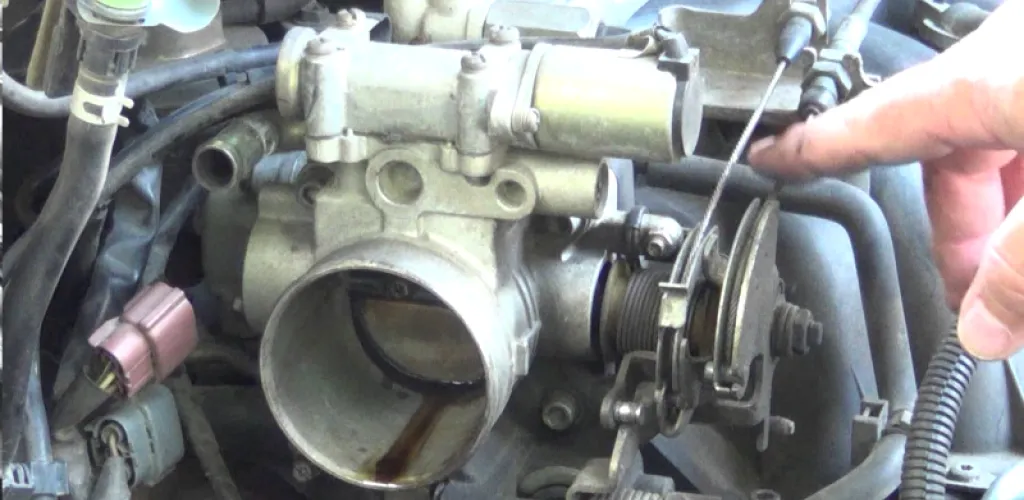

The throttle plate is a crucial component of the engine’s intake system, responsible for precise control of the amount of air entering the cylinders. Problems with this component can significantly affect engine performance, from unstable idle to power loss and increased fuel consumption.

Dirt and carbon deposits inside the housing, electrical issues, vacuum leaks, and malfunctioning idle control are the main indicators that it’s time to check or replace the throttle plate.

Throttle Plate: Function and Role

Drive-by-Wire Electronic System

- The accelerator pedal contains position sensors

- The ECU (engine control unit) receives data from the sensors

- The throttle plate is actuated by an electric motor commanded by the ECU

- The system allows much more precise control of the air–fuel mixture

This technology offers faster and more precise responses, but can be more sensitive to electrical problems.

Diagnosing a Faulty Throttle Plate

Detecting symptoms of a faulty throttle plate is essential to prevent more serious engine issues.

Main Symptoms of a Faulty Throttle Plate

1. Dirt and carbon deposits

Accumulation of residues inside the throttle housing, known as “coking”, is one of the most common problems. These deposits:

- Create a rough surface that disrupts the air flow

- Interfere with smooth operation of the throttle plate

- Cause an air–fuel mixture imbalance

- Can partially jam the plate in certain positions

2. Electrical system problems

In vehicles with electronic throttle control, connectivity issues can cause:

- Inaccurate data transmission to the ECU

- Activation of limp mode (safe mode)

- Restriction of engine power

- Erratic acceleration behavior

3. Vacuum leaks and sealing issues

Vacuum leaks in the intake system disturb pressure balance and can cause:

- Uncontrolled air flow

- Idle that is unstable or unusually high

- Difficulties starting

- Power loss on acceleration

4. Irregular idle

A clear symptom of throttle plate problems is an unstable idle, appearing as:

- Ticking idle speed fluctuations

- Very low idle (engine stalls)

- Very high idle (above 1000 rpm when warm)

- Jamming at stop or after start

5. Dashboard warning lights

The Check Engine light can illuminate due to:

- Error codes generated by the throttle sensor

- Detection of abnormal ECU values

- Communication problems within the electronic system

Cleaning the Throttle Plate

Regular cleaning of the throttle plate is essential preventive maintenance, especially on vehicles with over 100,000–150,000 km.

When Cleaning is Required

Indicators that it is time to clean include:

- Oscillating or unstable idle

- Accelerator pedal sticking when the engine is warm

- Decreased engine performance

- Higher fuel consumption

- Starting difficulties

Step-by-Step Cleaning Process

Preparation for Cleaning:

- Locate the throttle plate between the air filter and the intake manifold

- Obtain the specialized throttle plate cleaning solution and necessary materials

- Ensure you have protective equipment (gloves, goggles)

- Disconnect the negative battery terminal for safety

Disassembly and Cleaning:

- Disconnect the air hose from the throttle body

- Remove all connected hoses and cables

- Spray the cleaning solution on the internal surfaces

- Let it act according to the manufacturer’s instructions

- Clean carefully using soft cloths or fine brushes

- Repeat until all dirt is removed

Calibration after Cleaning

In many modern vehicles, throttle calibration is required after cleaning:

- The procedure is performed with specialized diagnostic equipment

- The ECU relearns the extreme positions of the throttle

- The process should be performed by an automotive specialist

- The calibration cost is relatively low compared to the benefits

Materials and Substances Needed for Cleaning

For effective cleaning you will need:

- Specialized throttle plate cleaning solution

- Soft, lint-free cloths

- Soft-bristled brushes

- Cotton swabs for hard-to-reach areas

- Protective rubber gloves

- Protective eyewear

Throttle Plate Replacement and Repair

When cleaning is no longer sufficient or the plate shows mechanical or electronic faults, replacement becomes necessary.

When to Replace the Throttle Plate

The throttle plate should be replaced in the following situations:

- Excessive mechanical wear of the plate or shaft

- Failures of the electric motor (for electronic throttles)

- Sensor position problems

- Cracks in the throttle body

- Irreversibly damaged threads

Refurbishment vs. Replacement with New Parts

Although refurbishment may seem economical, replacing with a new throttle plate offers several advantages:

Advantages of a New Part:

- Full manufacturer warranty

- Long-term reliability

- Optimal performance from day one

- Perfect compatibility with the original system

Disadvantages of Refurbishment:

- Risk of premature failure

- Lack of warranty or limited warranty

- Possible compatibility issues

- Hidden costs in case of failure

Electronic Diagnostics and Error Codes

Before replacement, a complete diagnostic with an automotive tester can reveal:

- Throttle system-specific error codes

- Real-time values from throttle sensors

- Status of ECU–throttle communication

- Related problems in the intake system

Preventive Maintenance and Recommendations

To extend the life of the throttle plate and avoid costly problems:

Recommended Maintenance Schedule

- At 60,000 km: First inspection and cleaning

- At 100,000 km: Thorough cleaning and component check

- At 150,000 km: Replacement evaluation

- Annually: Visual inspection and basic diagnostics

Preventive Measures

- Regular air filter replacement - prevents dirt ingress

- Use of high-quality fuels - reduces carbon deposits

- Avoid prolonged operation at low RPMs - helps burn off deposits

- Regular servicing - early problem detection

Costs Associated with Throttle Plate Maintenance

For proper budgeting, it’s important to know approximate costs:

Professional Cleaning:

- Labor: 100-200 RON

- Consumables: 30-50 RON

- Calibration: 50-100 RON

Throttle Plate Replacement:

- New throttle plate: 300-1500 RON (model-dependent)

- Mounting labor: 150-300 RON

- Programming and calibration: 100-200 RON

Complete Diagnostics:

- Diagnostic scan: 50-100 RON

- Detailed report: included in price

Investing in proper throttle plate maintenance pays off through fuel savings, improved engine performance, and avoiding more costly repairs to the fuel system or the engine itself.