- VVT solenoid controls oil flow to timing system for efficiency and performance

- Failure causes: burnt/corroded contacts or weak electromagnet, risking timing chain damage

- Symptoms: check engine light, unstable idle, degraded oil clogging solenoid, higher fuel use

- A defective solenoid can cause starting problems due to interrupted starter current

The Variable Valve Timing (VVT) solenoid is one of the most important innovations in modern automotive technology, essential for optimizing engine performance and reducing fuel consumption. This electronic component controls when the valves open and close, enabling the engine to run more efficiently in varying driving conditions.

Most modern cars are equipped with VVT technology, and the solenoid that controls it plays a crucial role in delivering the optimal oil flow to the timing system. Although it draws very little electrical power from the vehicle battery, this component is vital for achieving low fuel consumption and optimal engine performance.

How the VVT Solenoid Works

At engine startup, engagement of the solenoid is achieved by moving a metallic plunger downward, in order to overcome the spring force that pushes the plunger away from the coil. This movement closes the contact between the connections, connecting the battery to the starter and allowing a large current to flow through the starter motor contact.

When the solenoid is defective, the current flow is interrupted, causing starting problems. The most common causes are burning or corrosion of the contacts.

If the electromagnet of the VVT does not function properly, it results in improper lubrication, which can damage the timing chain and the engine’s timing system, generating very costly problems.

Symptoms of a Faulty VVT Solenoid

Check Engine Light on the Dashboard

Modern cars are equipped with electronic control units (ECUs) that constantly monitor all engine activities. The ECU compares and reports all engine actions, and in the case of a fault in the VVT solenoid, the check engine light will illuminate on the dashboard.

The appearance of this light requires urgent inspection at an authorized service, where a specialist can diagnose the problem and clear the error code from the ECU memory.

Unstable and Oscillating Idle

Another manifestation of a faulty VVT solenoid is an excessive flow of oil to the VVT system, which can cause an unstable idle. The RPM values will fluctuate uncontrollably.

Ignorance of this issue can lead to:

- Premature engine wear

- Damage to internal components

- The need to replace the engine within a short period

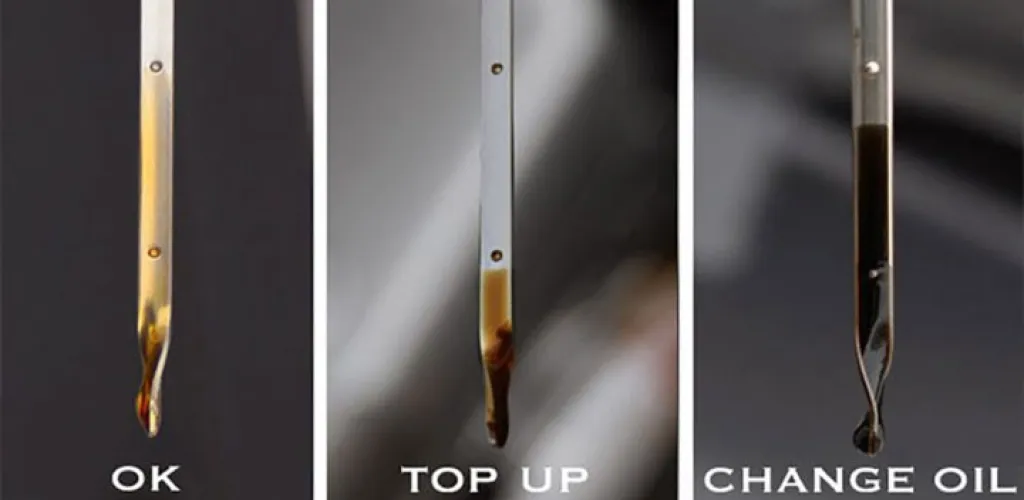

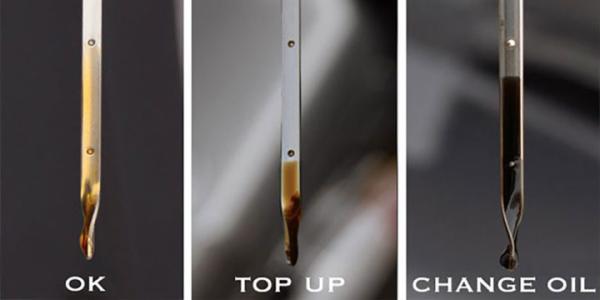

Dirty or Deteriorated Engine Oil

The quality of engine oil directly affects the performance of the VVT solenoid. For optimal operation, the oil must be clean and maintain its lubrication properties. When the oil contains many impurities, the oil viscosity decreases significantly, causing the VVT solenoid to clog.

Consequences of degraded oil include:

- Blocking the VVT solenoid

- Affecting the timing chain

- Damaging the transmission system

Increased Fuel Consumption

The VVT solenoid manages the timing of the opening and closing of the valves to achieve optimal fuel consumption. A fault at this level manifests as:

- Significantly higher fuel consumption

- Persistent fuel odor

- Reduced engine performance

- Increased pollutant emissions

The VVT Solenoid Replacement Process

Replacing a defective VVT solenoid can be done at a service center or, with the right knowledge and tools, in your own garage. The procedure requires careful attention and following specific steps.

Equipment Needed

Before starting work, ensure you have:

- Set of wrenches and screwdrivers

- Pliers

- New VVT solenoid

- Gasket lubricant

- Protective gloves

Steps for Replacement

- Disconnecting the battery

- Loosen and remove the negative terminal (-) first

- Then disconnect the positive terminal (+)

- Remove the battery from the engine compartment

- Ensure the terminals do not touch to avoid a short circuit

- Removing the engine cover Modern engines are protected by plastic covers:

- Identify and remove all mounting bolts

- Carefully lift the engine cover

- Place the cover in a safe spot for reinstallation

- Locating the VVT solenoid Look for the VVT solenoid in the engine bay:

- It is usually near the timing system

- Compare with the new part for correct identification

- Note the position and orientation for subsequent mounting

- Removing mounting components Remove the mounting elements:

- Usually a single bolt holds the solenoid, but some models have two

- Keep the bolts in a safe place

- Check the condition of the bolts and replace if damaged

- Extracting the defective solenoid Carefully remove the old solenoid:

- First disconnect the electrical connector

- Use pliers to grip the metal part

- Pull or gently twist to withdraw

- Avoid excessive force that could damage other components

- Inspecting and cleaning the area Check the mounting area:

- Ensure no parts of the old solenoid remain

- Inspect the O-ring/gasket condition

- Clean all dust and residue

- Inspect the bore for damage

- Preparing and installing the new solenoid Before mounting:

- Lubricate the new solenoid’s seals with engine oil

- Verify the part’s compatibility with the vehicle

- Ensure all components are clean

- Securing and fastening the solenoid Install the new solenoid:

- Insert the solenoid into the correct position

- Tighten the bolts to the manufacturer’s specified torque

- Avoid over-tightening that could damage threads

- Reconnecting the systems Complete the installation:

- Reconnect the electrical connector to the solenoid

- Refit the engine cover

- Reinstall the battery and connect the terminals (+ first, then -)

- Check all connections

Costs and Economic Considerations

Repair costs for VVT solenoid issues vary depending on:

- Vehicle make and model

- The complexity of access to the component

- Cost of the replacement part

- Labor rate at the service center

Carrying out the work in a do-it-yourself approach can save on labor costs but requires technical knowledge and the right tools.

Prevention of VVT Solenoid Failures

To avoid VVT solenoid problems:

- Change engine oil regularly according to the manufacturer’s recommendations

- Use high-quality oil

- Replace the oil filter with every oil change

- Perform periodic service checks

- Adhere to maintenance intervals

Conclusion

The VVT solenoid is a vital component for the optimum performance of the modern engine and for fuel efficiency. A failure of this part can lead to serious issues, including accelerated engine wear and the need for replacement.

Timely recognition of symptoms and prompt intervention can prevent costly engine damage. Whether you choose professional repair or DIY replacement, using quality parts and following correct technical procedures is essential.

A proper preventive maintenance regimen, especially regular engine oil changes, can significantly extend the life of the VVT solenoid and the entire timing system.

Photo sources: cartreatments.com, genuinegmparts.com, naijacarnews.com, quakertownmitsubishi.com, autorepairhelp.us