- Compression ratio is the volume ratio between BDC and TDC.

- Gasoline: 8–10:1 NA; up to 14:1 high-performance; turbo 6–9:1.

- Diesel engines: 14–18:1 standard; up to 23:1 for high-performance.

- Common causes of compression loss include worn valves, gaskets, and piston rings.

Engine compression is one of the most important parameters that determine the performance and efficiency of an internal combustion engine. Understanding the normal compression values for different types of engines can be essential for both diagnostics and assessing the overall condition of the engine.

Compression in an internal combustion engine represents the ratio between the combustion chamber volume—in other words, the ratio between the largest volume (when the piston is at bottom dead center) and the smallest volume (when the piston is at top dead center).

Importance of compression in engine operation

An engine without compression or with a low compression value cannot ignite the fuel efficiently. A high compression ratio is desirable because it allows an engine to produce more mechanical energy from a given amount of air–fuel mixture, thanks to higher thermal efficiency.

Engines with higher compression have the following advantages:

- Higher thermal efficiency

- Lower fuel consumption

- More power per liter of displacement

- Quicker response to acceleration

What compression should a gasoline engine have?

Gasoline engines have a lower compression ratio than diesels, because the air–fuel mixture is ignited by a spark and does not require the air to be heated too much by compression.

Normal values for gasoline engines:

- Naturally aspirated engines: 8:1–10:1

- High-performance naturally aspirated engines: 10:1–12:1

- High-performance engines: up to 14:1 (e.g., Ferrari 458 Italia)

- Turbocharged engines: 6:1–9:1 (due to forced induction)

Gasoline engines with lower compression are more tolerant of lower quality fuel and generate less knock.

What compression should a diesel engine have?

Diesel engines operate on a completely different principle than gasoline ones. They do not require a spark to detonate the air–fuel mixture; they rely on compression ignition.

Normal values for diesel engines:

- Standard diesel engines: 14:1–18:1

- Modern diesel engines: 16:1–20:1

- High-performance diesel engines: up to 23:1

The mixture in diesel engines self-ignites by compressing the air in the chamber, reaching temperatures of 500–700°C, sufficient for spontaneous ignition of the injected fuel. This high compression is essential for proper diesel engine operation.

Common causes of compression loss

If your car’s engine shows compression values lower than normal, it indicates technical issues that are usually costly to remedy.

Where a piston can lose compression in the combustion chamber:

1. Through the valves

- Worn intake or exhaust valves

- Worn valve seats

- Incorrect valve clearance adjustment

- Burnt or bent valves

2. Through the head gasket

- Head gasket damaged or burnt

- Warping of the cylinder head due to overheating

- Incorrect replacement or use of an improper gasket

3. Through the piston rings

- Worn piston rings

- Worn or scored cylinder

- Cracked or deformed piston

- Carbon buildup that traps the rings

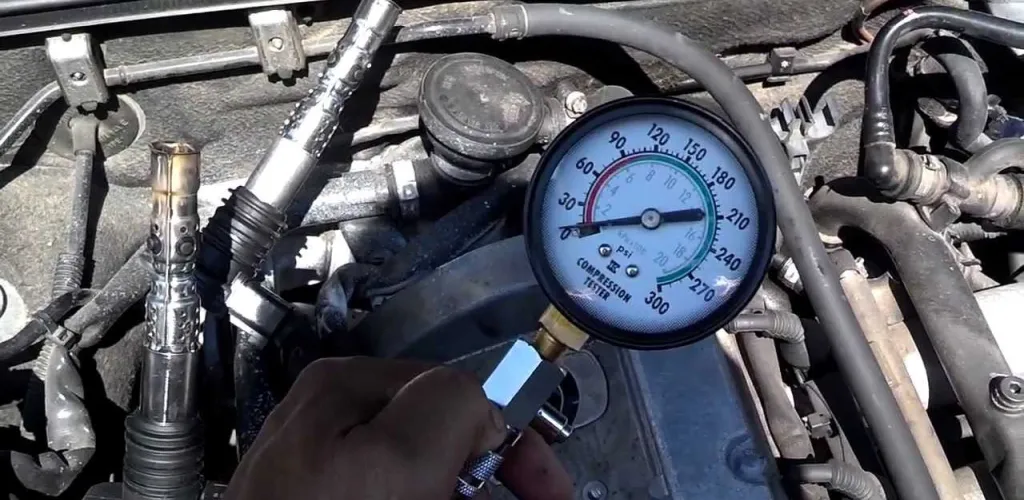

How to check engine compression

Compression testing is performed with a special device called a compression tester and requires:

- Removing all spark plugs (for gasoline) or injectors (for diesel)

- The engine to be at operating temperature

- A fully charged battery

- Testing each cylinder individually

Measured values should be uniform across cylinders, with a maximum difference of 10–15% to indicate a good engine condition.

Photo source: youtube.com, dannysengineportal.com