- Gasoline engines: 6-10 bar; diesel: 14-23 bar compression.

- Requires compression tester, wrenches, helper; warm engine, disconnect ignition.

- Crank 6-8 revolutions per cylinder; compare readings, note differences.

- Normal diff: gasoline ≤1 bar; diesel ≤2 bar; below needs intervention.

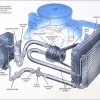

Compression testing is one of the most important diagnostics you can perform on an engine, providing essential insight into its internal condition. For any car owner or for those looking to buy a used car, understanding this test can prevent costly problems down the road.

A healthy gasoline engine should have compression between 6 and 10 bar in each cylinder, while diesel engines operate at much higher compression, between 14 and 23 bar. These values reflect the pistons’, rings’, and valves’ ability to create a perfect seal in the combustion chamber.

Why the compression test matters

Compression of the engine directly indicates the health of critical internal components:

- Piston rings – responsible for sealing between the piston and the cylinder

- Intake and exhaust valves – must close perfectly to maintain compression

- Cylinder head gasket – ensures sealing between the head and the block

- Cylinder walls – wear can affect compression

If you notice the engine no longer has the same power as before, consumes more fuel, or exhaust smoke becomes thicker, a compression test can identify the source of the problem before it becomes much more expensive.

Equipment needed for the compression test

To perform the test correctly you will need:

- A compression tester (engine-specific manometer)

- A set of wrenches for removing spark plugs

- A person to help with cranking the engine

- Protective gloves

- A flashlight for good visibility

How to perform the compression test step by step

Engine preparation

- Warm up the engine to operating temperature – this is crucial for accurate measurements

- Turn off the engine and let it cool for about 10 minutes

- Disconnect the ignition system to prevent accidents

Disassembling components

- Carefully remove the spark plug wires, marking the order to reconnect them correctly

- Disconnect the fuel supply hoses from the injector rail if necessary

- Remove all spark plugs using the appropriate wrench – this step is essential to allow the engine to turn freely

Taking measurements

- Insert the compression tester into the first spark plug hole, ensuring it is securely fixed

- Ask your helper to crank the engine and turn it for 6-8 full revolutions of the crankshaft

- Read the value shown on the compression gauge

- Note the result and reset the gauge

- Repeat the procedure for each cylinder

Interpreting the results

Normal compression values

Gasoline engines:

- Normal compression: 6-10 bar

- Maximum difference between cylinders: 1 bar

- Compression below 6 bar: serious problem

Diesel engines:

- Normal compression: 14-23 bar

- Maximum difference between cylinders: 2 bar

- Compression below 14 bar: requires intervention

Common problems identified by the compression test

Low compression uniform across all cylinders:

- General engine wear

- Timing issues

- Worn piston rings

Low compression in a single cylinder:

- Burned or warped valve

- Cylinder head gasket issue

- Cracks in the affected piston

Variable compression between cylinders:

- Uneven wear

- Valve timing problems

- Point failures of components

When to call a specialist

Although the compression test can be performed at home, certain situations require the expertise of a professional mechanic:

- Results are hard to interpret

- Compression is far below normal values

- Suspicions of serious engine problems exist

- You lack the necessary experience with engine components

A specialist can perform additional tests as well, such as an oil in cylinders test or a leak-down test to pinpoint the exact source of the issue.

Frequency of compression testing

For optimal maintenance, the compression test should be performed:

- When buying a used car

- Every 50,000–80,000 km

- When symptoms of reduced performance appear

- During a major engine overhaul

Conclusion

The compression test is a simple yet highly valuable procedure for assessing the engine’s condition. With a modest investment in a compression tester and a little time, you can obtain crucial information about your engine’s health. Whether you are shopping for a used car or monitoring the current vehicle, this test can save you significant sums by identifying problems early.

Remember that test results should be interpreted in the context of the engine’s age and mileage, and when in doubt, it is always advisable to consult an experienced mechanic.

Sursa foto: popularmechanics.com