- AC only blows warm air when the clutch fails to engage.

- Unusual noises from the compressor (grinding, crushing/impact, repeated clicks) indicate clutch wear or damage.

- Refrigerant leaks show oil-stained spots near the compressor, low refrigerant, reduced cooling.

- Perform basic operation check: run at max power, observe vent temps, noises, behavior.

Many drivers only realize the importance of the air conditioning system when it stops working, especially on hot summer days stuck in traffic. The AC compressor clutch is a critical component of this system, and its failure can lead to a complete interruption of cooling.

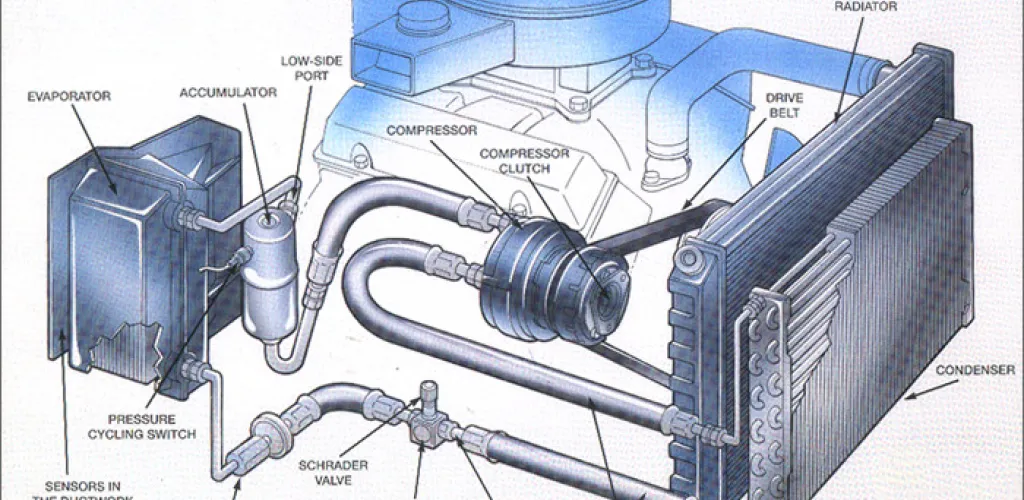

The compressor is the heart of the air conditioning system, responsible for pressurizing the refrigerant and circulating it through the circuit. The compressor clutch, also known as the electromagnetic clutch, controls the engagement and disengagement of the compressor according to the system’s demands.

Symptoms of a faulty AC compressor clutch

Identifying problems with the AC compressor clutch early can prevent a total system failure and extra repair costs.

Air conditioning only blows warm air

The most evident symptom of a problem with the AC compressor clutch is the lack of cold air in the cabin. When the clutch fails to engage the compressor, it cannot pressurize the refrigerant, resulting in air flow at ambient temperature.

This issue can have several causes:

- Defect in the electromagnetic coil in the clutch

- Wear of the friction disc

- Problems with the power supply circuit

Unusual noises from the compressor

AC compressor contains several moving components that can wear over time. A faulty clutch can cause:

- Grinding noise: indicates wear of bearings inside the compressor

- Crushing/impact noise: suggests damage to the blades or piston

- Repeated clicks: may indicate repeated attempts to engage a faulty clutch

These sounds typically appear when the climate control system is active and indicate the need for urgent intervention.

Refrigerant leaks

Worn bearings in the AC compressor can allow refrigerant to leak. These leaks show as:

- Oil-stained spots near the compressor

- Low refrigerant level in the system

- Reduced performance of the climate system

It’s important to note that refrigerant also contains oil for lubricating the compressor, which is why leaks often appear oily.

Problems with the electromagnetic clutch

The compressor clutch engages the compressor through an electromagnetic field. Failures can include:

- Friction disc wear: reduces torque transfer capability

- Coil damage: prevents creating the required magnetic field

- Bearing problems: cause vibrations and noise

In many cases, replacing only the clutch can be enough, being more economical than swapping the entire compressor.

Methods of diagnosing a faulty compressor

Correct diagnosis of AC compressor problems requires a systematic approach and basic technical knowledge.

Basic operation check

The first step is to run the climate control system at maximum power with the engine running. Observe:

- The temperature of air coming from the vents

- Noises from the compressor

- System behavior at different settings

Visual inspection

With the hood open, visually inspect the compressor for:

- Signs of corrosion: rust can affect component operation

- Visible leaks: oil spots indicate sealing issues

- Serpentine belt condition: a worn belt can affect the drive

- Electrical connections: ensure they are secure and free of corrosion

Testing the electromagnetic clutch

The clutch is located at the front of the compressor and can be tested by:

- Check free rotation: with the engine off, the pulley should rotate freely

- Engagement test: with the AC on, the clutch should engage with an audible click

- Gap measurement: the distance between the pulley and the coil should be between 0.4-0.8 mm

Measuring system pressures

A healthy AC system should maintain certain pressures:

- High pressure: 12-16 bar (depending on ambient temperature)

- Low pressure: 2-3 bar

Abnormal pressures may indicate:

- Leaks in the system (low pressures)

- Circuit blockage (very high pressures)

- Faulty compressor (small pressure differences)

Manual testing of the clutch

Manual testing of the compressor clutch requires caution and basic knowledge of automotive electrical systems.

Safety precautions

Before any intervention:

- Wear protective gear (gloves, goggles)

- Ensure the engine is off and cooled

- Disconnect the battery to avoid short circuits

Testing methods

Multimeter testing:

- Measure the coil resistance (should be 3-5 ohms)

- Check electrical circuit continuity

- Test 12V supply to the compressor clutch

Direct power testing:

- Connect 12V directly to the clutch terminals

- Observe whether the disc engages

- Listen for the engaging click

CAUTION: This method must be used with maximum care to avoid damaging the compressor.

Interpreting the results

- Clutch engages: the problem may be in the control circuit

- Clutch does not engage: replacement required

- Partial engagement: the friction disc is worn

Costs and repair options

Repair costs for the AC compressor clutch vary significantly depending on several factors.

Factors influencing costs

- Vehicle make and model: premium cars have more expensive components

- Type of repair: replacing only the clutch vs. the entire compressor

- Service location: official dealerships tend to charge higher rates

- Parts availability: rare or import components are more expensive

Repair options

Replacing only the clutch:

- Lower cost (500-1,500 RON)

- Shorter labor time

- Suitable for localized faults

Replacing the compressor entirely:

- Higher cost (1,500-4,000 RON)

- Extended warranty

- Recommended for heavily worn compressors

Reconditioning the compressor:

- Mid-range option

- Available for certain models

- May include updates from the original model

Additional considerations

When replacing the AC compressor, it is recommended to also replace:

- Desiccant filter

- Refrigerant

- Compressor oil

These preventive measures ensure optimal long-term operation and can prevent premature failure of new components.

Preventive maintenance

To avoid AC compressor clutch problems, follow these simple rules:

- Use the AC system at least once a month, even in winter

- Periodically check the refrigerant level

- Replace the cabin air filter according to the maintenance schedule

- Service the AC system every 2-3 years

These simple measures can significantly extend the life of the climate control system and prevent costly repairs.