- Repairing auto parts instead of replacing cuts about 30,000 tons CO2 annually

- Small increase in repair share could significantly aid Europe’s emission reduction targets

- Eco-friendly repairs avoid energy-intensive manufacturing, reduce waste, and keep materials in use

- Allianz advocates green certificate system to standardize sustainability criteria for auto service centers

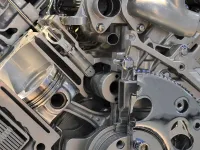

The automotive industry faces growing pressure to reduce its environmental footprint, and insurers are beginning to play a crucial role in this transformation. A recent Allianz SE study shows that choosing between repairing and replacing auto parts can have a significant impact on carbon emissions.

A recent Allianz SE study shows that choosing between repairing and replacing auto parts can have a significant impact on carbon emissions.

Impact of repairs on CO2 emissions

According to research presented at the 10th edition of Allianz Motor Day, switching the strategy from replacing parts to repairing them can lead to a reduction of 30,000 tons of CO2 per year. This figure represents the annual emissions of approximately 5,100 households.

Klaus-Peter Roehler, a member of Allianz SE’s management board, explains: “In auto insurance we have a multitude of ways at our disposal to reduce CO2 emissions in the atmosphere. In this context, finding ways to repair a component rather than replace it is extremely important.”

Context of pollution in Romania

The context of Romania’s environment is alarming. Statistics show that:

- Between 16,000 and 26,500 Romanians die prematurely each year due to pollution

- On average, about two Romanians per hour die due to the effects of pollution

- Bucharest ranks among the most polluted European cities

- Over half of cars on Romanian roads are over 16 years old

These data, provided by the European Environment Agency and the World Health Organization, highlight the urgency of adopting concrete measures to reduce pollution.

Technical advantages of repairs over replacements

Reducing the carbon footprint

Most traffic accidents affect the vehicle’s bodywork. In such situations, there is an eco-friendly repair option that:

- Avoids the energy-intensive process of manufacturing new components

- Reduces transport and packaging of spare parts

- Minimizes waste from disposing of defective parts

- Keeps existing materials in the economic cycle

Manufacturing process vs. repair

Manufacturing a new auto part involves:

- Extraction and processing of raw materials

- Energy-intensive industrial processes

- Transport over long distances

- Packaging and distribution

- Disposal of the old part

In contrast, repair requires only:

- Repair materials in small quantities

- Local workmanship processes

- Maintaining the original structure of the part

European-level impact

According to Allianz experts’ calculations, an increase of just two percentage points in the share of auto repairs annually could have a significant continental effect. This relatively small shift in approach could substantially contribute to Europe’s emission reduction targets.

Green certificate system

Allianz supports the implementation of a green certificate system for auto service centers, with the aim to:

- Standardize sustainability criteria at the European level

- Empower customers to make informed choices

- Encourage service centers to adopt sustainable practices

- Create transparency in the industry

Initiatives for the future of the auto industry

Net-Zero Insurance Alliance (NZIA)

Allianz is a co-founder of this alliance which supports:

- Reducing emissions by 55% by 2030

- Achieving emissions neutrality by 2050

- Supporting electrification of the vehicle fleet

- Promoting green technologies in the auto industry

Electrification of transport

The company actively participates in:

- Supporting initiatives related to the electric vehicle market

- Developing tailored insurance solutions

- Promoting charging infrastructure

- Educating consumers about the benefits of electric vehicles

Recommendations for vehicle owners

When choosing a service center

- Choose certified service centers that are sustainable

- Ask for explanations about the repair methods used

- Prefer repair to replacement when possible

- Choose refurbished or quality second-hand parts

Vehicle maintenance

- Carry out regular preventive maintenance

- Repair minor faults before they worsen

- Use quality parts to increase durability

- Consider eco-friendly upgrades when appropriate

Conclusion

The Allianz study shows that the auto insurance industry can play a crucial role in reducing pollution by promoting repairs over unnecessary replacements. With a potential reduction of 30,000 tons of CO2 per year through minor shifts in approach, this strategy marks an important step toward a more sustainable future for the auto industry.

Transforming toward greener practices in auto repair is not only an environmental necessity but also an economic opportunity for all stakeholders: insurers, auto repair shops, and vehicle owners.