- Turbochargers use exhaust gases to compress intake air and boost power.

- Twin turbo means two turbos; can be sequential or parallel.

- Sequential twins use a small turbo for low RPM and a larger for high RPM.

- Sequential systems reduce lag and improve throttle response but add complexity and cost.

Technological evolution in the automotive industry has turned modern engines into increasingly complex and high-performance systems. The terms biturbo and twin turbo appear frequently in performance car specifications, but what do these designations truly mean, and what are the differences between them? In this article, we will analyze in detail the two concepts, how turbochargers work, and the advantages of each system.

The engine is the heart of any vehicle, and understanding how forced induction systems with turbochargers operate can help you make the right choice when buying a new car or better understand the capabilities of the vehicle you already own.

What is a turbocharger and how does it work

Before discussing the differences between biturbo and twin turbo systems, it is essential to understand what a turbocharger is and how it works. A turbocharger is a mechanical device driven by a turbine that uses exhaust gases to compress the air entering the internal combustion engine.

The operating principle is relatively simple: hot exhaust gases drive a turbine connected via a shaft to a compressor. This compressor draws air from the atmosphere, compresses it, and sends it to the engine’s intake manifold. The compressed air contains more oxygen per unit volume, allowing the engine to burn more fuel and thus generate more power.

Advantages of turbocharging include:

- Significant increase in engine power and torque

- Maintaining a smaller displacement (downsizing)

- Improved fuel efficiency in certain operating conditions

- Lower emissions through more complete combustion

Engines equipped with twin turbo systems

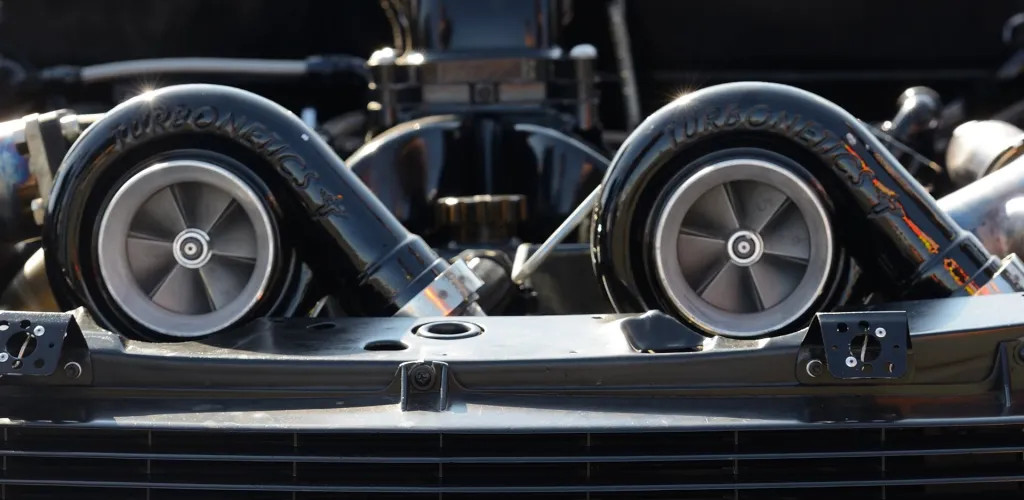

When we talk about a twin turbo engine, we refer to a propulsion group equipped with two distinct turbochargers that work to compress air in the intake system. This type of configuration can be implemented in two main modes: sequential or parallel.

Sequential twin turbo configuration

In sequential twin turbo systems, the engine uses two turbochargers of different sizes that come into operation at different RPM ranges. The smaller turbo (usually 30-40% smaller in volume) is optimized for low and mid-range speeds, where reduced inertia allows a quick spool and largely eliminates turbo lag.

At higher ranges, when the engine reaches roughly 3000-4000 rpm (depending on configuration), the switching valve (wastegate) directs exhaust gases to the larger turbo. This one takes over and provides the air flow necessary for maximum performance at high revs. The transition from one turbo to the other is electronically controlled to be as smooth as possible.

Advantages of the sequential system:

- Excellent throttle response across the entire RPM range

- Near-complete elimination of turbo lag

- Superior fuel efficiency

Disadvantages:

- Increased mechanical complexity

- Higher production and maintenance costs

- Need for sophisticated electronic calibration

Parallel twin turbo configuration

This is the most common configuration for engines with two turbochargers. The system uses two identically sized and capable turbochargers, each serving half the engine’s cylinders. In V6 or V8 engines, for example, each turbo serves one bank of cylinders.

Both turbos operate simultaneously, sharing the compression workload evenly. The air compressed by both units meets in the common intake manifold before entering the combustion chambers. This configuration provides more redundancy — if one turbo develops a fault, the other can continue to operate, allowing the vehicle to reach service (though with reduced performance).

Advantages of the parallel system:

- Relatively simple design and installation

- Increased reliability by dividing the workload

- Lower production costs compared with the sequential system

- Uniform acceleration response

- Easier diagnostics

Disadvantages:

- More pronounced turbo lag at low ranges compared with the sequential system

- Requires ample space in the engine bay

Engines equipped with biturbo systems

Now we reach the core of the discussion: what is the difference between biturbo and twin turbo? The simple answer is that there is no real technical difference. The term “biturbo” is simply another name for the same concept of an engine equipped with two turbochargers.

Differences in terminology come more from automaker marketing strategies or the desire to differentiate a brand through patents and proprietary terminology. For example, BMW popularized the term “TwinPower Turbo” (which, ironically, often refers to a single twin-scroll turbo), while Mercedes-AMG frequently uses the term “biturbo” for its V8 engines.

The operation of a biturbo engine is identical to that of a parallel twin turbo system: each turbocharger serves a set of cylinders, and both operate simultaneously to provide the compressed air the engine needs. In V engines, the typical configuration is one turbo per bank of cylinders, which optimizes exhaust flow and reduces the length of piping.

Advantages of two-turbo systems

Regardless of the terminology used, engines equipped with twin turbo systems offer multiple advantages:

Superior performance Power and torque are increased, enabling impressive acceleration and high top speeds. 3.0-liter biturbo engines can easily produce over 400 hp, rivaling naturally aspirated 5.0-liter or larger engines.

Improved efficiency Although it may seem counterintuitive, smaller turbocharged engines can be more efficient than larger naturally aspirated engines, especially in urban traffic conditions or at steady highway speeds.

Reliability through redundancy In parallel configurations, if one turbo develops issues, the vehicle can continue to run with the other, providing additional safety.

Optimized response In sequential systems, the combination of the small turbo for low ranges and the large one for high ranges offers excellent response across the entire usable range.

Maintenance and reliability considerations

Engines with twin-turbo systems require heightened maintenance attention:

Quality oil Turbochargers spin at extremely high speeds (up to 250,000 rpm) and require the highest quality oil. Regular oil changes are essential — delays can lead to premature wear of the turbo bearings.

Cooling-off period After spirited driving, it is recommended to let the engine idle for 30-60 seconds before shutting off to allow the turbochargers to cool gradually.

Cooling system Maintaining the cooling system in optimal condition is crucial. Many modern turbochargers are cooled by both oil and coolant.

Air filters Regular replacement of air filters prevents contaminants from entering and potentially damaging the turbine blades.

Twin turbo vs. single turbo: which is better?

Although this article focused on the difference between biturbo and twin turbo (which we have established are the same), it is worth comparing two-turbo systems with single-turbo setups.

Advantages of a single turbo:

- Mechanical simplicity and fewer components

- Lower maintenance costs

- Less space required in the engine bay

- Potential for greater tuning for race applications

Advantages of twin turbo:

- Faster throttle response

- More even power delivery

- Reduced turbo lag

- Suitable for multi-cylinder engines (V6, V8, V12)

Notable manufacturers and applications

Various automaker brands have adopted twin turbo/biturbo technology for their performance models:

- BMW extensively uses twin turbo engines in the M series and in high-capacity diesel engines. The classic example is the 4.4-liter V8 biturbo S63 powering the M5 and M8.

- Mercedes-AMG is renowned for its biturbo V8 engines, such as the 4.0-liter M177/M178 found in AMG GT, C63, E63, and others.

- Porsche uses twin turbo configurations for the 911 Turbo, Cayenne Turbo, and also for the V8 engines in the Panamera Turbo.

- Nissan made history with the RB26DETT twin turbo engine in the legendary GT-R R34, and the modern version continues the tradition with the VR38DETT engine.

Conclusion

In the end, the difference between the terms ‘biturbo’ and ‘twin turbo’ is more linguistic and marketing-oriented than technical. Both terms describe the same concept: an engine equipped with two turbochargers that work together to increase performance.

The only real technical distinction in the world of multi-turbo engines is between the sequential configuration (where differently sized turbos operate at different RPM ranges) and the parallel configuration (where two identical turbos operate simultaneously).

When you drive a vehicle equipped with such a system, you will enjoy superior performance, abundant torque, and excellent acceleration response. Whether the manufacturer calls the system “biturbo”, “twin turbo”, or something else, what truly matters is the quality of its implementation, proper maintenance, and the pleasure of driving a car with a powerful and efficient engine.

For automotive enthusiasts seeking maximum performance, twin-turbo systems represent the pinnacle of current turbocharging technology, offering an excellent mix of power, efficiency, and driving pleasure.