- Introduced in 2013 to replace the problematic 1.6 EcoBoost for reliability

- 1498 cc aluminum block with iron sleeves and a 76.40 mm stroke

- BorgWarner turbo with water-to-air intercooler for efficient cooling and quick response

- Direct fuel injection with six-hole injectors and hot powder metallurgy connecting rods

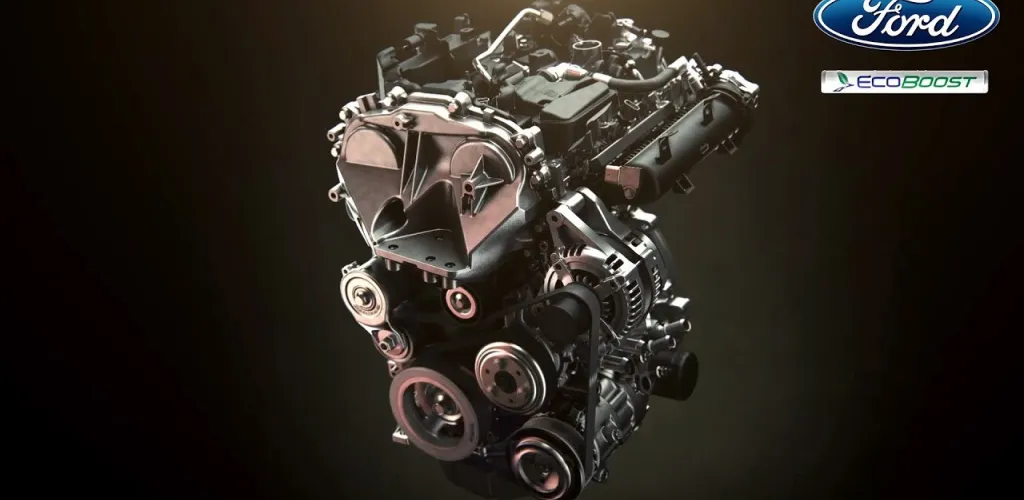

Ford EcoBoost 1.5-liter engine represents an important evolution in Ford’s powertrain range, launched in 2013 in response to issues encountered with the 1.6 EcoBoost version. This unit combines fuel efficiency with decent performance and has been used across a wide range of popular Ford models in Europe and Romania.

Development and technical context

Ford Motor Company designed the 1.5 EcoBoost engine starting from the 1.0-liter EcoBoost I-3 architecture, but adapted to a four-cylinder configuration. This design decision was not accidental - Ford engineers analyzed overheating and reliability issues encountered with the 1.6 EcoBoost engine and implemented improved cooling solutions early in the design phase.

The engine debuted on the Ford Fusion 2014 (known in Europe as Mondeo from 2015) and was quickly extended across Ford’s range of compact and mid-size models. The company’s strategy was to replace almost completely the 1.6-liter version with the new 1.5-liter unit, benefiting from more advanced technologies and higher reliability.

Block and major rotating assembly

Engine block and rotating assembly

The 1.5 EcoBoost uses an aluminum cylinder block with cast iron sleeves, similar to the 1.6 version. The open design of the block allows efficient cooling of the cylinders, preventing hot spots that can lead to detonation or premature wear.

The crankshaft is made of cast iron and features four counterweights for vibration balancing and five main bearings for rigidity and durability. The short stroke of 76.40 mm, combined with the standard bore, yields a displacement of 1498 cc. This configuration provides a good balance between low-end torque and the ability to reach high revs without excessive mechanical stress.

Connecting rods are produced using hot powder metallurgy processing, followed by the finishing steps for the cylinder bores. This technology ensures excellent dimensional precision and superior resistance to cyclic loading. The aluminum pistons are hyper-eutectic with asymmetric skirts coated with a low-friction layer, contributing to the engine’s high mechanical efficiency.

Intake and turbocharging

The engine uses a Borg Warner turbocharger with low inertia and a rapid response, optimized to eliminate throttle lag. The turbocharger is equipped with an active separator that helps reduce crankcase gas emissions and maintain optimal boost pressure.

A distinctive feature is the water-to-air intercooler integrated directly into the plastic intake manifold. This technical solution offers significant advantages over traditional air-to-air intercoolers: more efficient cooling of boosted air, compact size, and a faster response to load changes. The cooling water circulates in a separate circuit, keeping the intake air temperature at optimal levels even under heavy use.

Fueling and induction

High-pressure direct fuel injection is one of the key components of the EcoBoost engine. The six-hole injectors are mounted centrally in the head, close to the spark plugs, allowing optimal fuel atomization directly into the combustion chamber. This central position ensures homogeneous air-fuel mixing and complete combustion, reducing emissions and improving thermal efficiency.

The high-pressure pump is driven directly by the camshaft and can generate pressures above 200 bar, required for fine fuel atomization. The engine management system Bosch MED17 precisely controls the timing and amount of fuel injected, adapting in real time to operating conditions.

The electronic throttle body (drive-by-wire) eliminates the traditional mechanical linkage, enabling finer control of air flow and optimized response to the accelerator pedal in different driving modes.

Valvetrain and cylinder head

The aluminum cylinder head uses a DOHC (Double Overhead Camshaft) configuration with four valves per cylinder. The two camshafts are driven by a belt or chain (depending on the production year), with variable valve timing to optimize performance across the RPM range.

This system allows the engine to benefit from high torque at low revs (important for urban use) and increased power at high revs, without significant compromises in fuel consumption.

Technical specifications

Manufacturer: Ford plant in Craiova, Romania

Production years: 2014 - present

Architecture:

- Block material: Aluminum with iron sleeves

- Cylinder head material: Aluminum

- Configuration: Inline four-cylinder

- Displacement: 1498 cc

- Bore x stroke: 77 x 76.40 mm

Valvetrain:

- System: DOHC (Double Overhead Camshaft)

- Number of valves: 16 (4 per cylinder)

- Firing order: 1-3-4-2

Performance:

- Max power: 148-181 HP (110-135 kW) at 6000 rpm

- Max torque: 240 Nm between 1500-4500 rpm

- Compression ratio: 10.0:1

Fuel system:

- Type: Direct fuel injection

- Engine management: Bosch MED17

- Boost: Borg Warner turbocharger with water-to-air intercooler

- Emissions: Euro 6

Lubrication:

- Recommended oil: SAE 5W-20

- Oil capacity: 4.1 liters

- Oil change interval: 15000 km (or yearly)

Applications: Ford Focus (2014+), Ford C-Max (2015+), Ford Fusion/Mondeo (2014+), Ford Escape/Kuga (2016+), Ford Galaxy (2015+), Ford S-Max (2015+)

Versions and power levels

The 1.5 EcoBoost engine is available in several power configurations, tailored to the needs of each model:

- 150 HP version - the most widespread variant, offering an optimal balance between performance and consumption. The 240 Nm torque available from 1500 rpm ensures strong acceleration in urban traffic and adequate overtaking capability.

- 160-165 HP version - used on sportier or heavier models, such as the Kuga. This version benefits from a slightly different ECU calibration and possibly slightly higher boost pressure.

- 180-182 HP version - the most powerful variant, reserved for models like Mondeo and S-Max in sport configurations. This version may include additional modifications to exhaust and cooling systems.

Advantages and strengths

Efficiency and performance

The combination of turbocharger and direct injection ensures high thermal efficiency, with average consumption around 5.5-7 L/100 km depending on the model and driving style. The torque available from low revs makes the engine very pleasant in daily use, eliminating the need for frequent gear changes.

Reliability improvements over the 1.6 EcoBoost

The major issue of the 1.6 EcoBoost engine - head overheating and cracking in critical areas - was addressed in the 1.5-liter version through an improved cooling system. The open block design and optimized cooling circuits prevent hot spots.

The turbocharger benefits from lower operating temperatures due to more efficient exhaust flow, translating to greater durability. Many owners report functional turbos after over 200,000 km without major interventions.

Reasonable maintenance costs

Compared with other turbocharged gasoline engines in the segment, the 1.5 EcoBoost does not present exaggerated maintenance costs. Parts are relatively affordable, and Ford’s service network is widespread in Romania.

Common problems and reliability aspects

Injector clogging

The most frequently reported issue by owners is progressive clogging of the fuel injectors. This problem is mainly caused by the quality of fuel used. In Romania, where fuel quality can vary significantly between stations, it is essential to refuel at trusted fueling stations, preferably from larger networks.

Symptoms include: rough idle, difficult cold start, power loss on acceleration, increased consumption, and the check engine light coming on. Cleaning injectors can cost between 400 and 800 lei, depending on the service, and in severe cases replacement may be necessary (1500-2500 lei per injector).

Deposits on intake valves

A common issue with direct-injection systems is the buildup of carbon deposits on the rear face of the intake valves. In engines with intake-side injection, the sprayed fuel naturally cleans these valves. With direct injection, fuel goes directly into the chamber, leaving the valves exposed to oil vapors and crankcase gases.

These deposits accumulate over time and can cause: uneven idle, power loss, increased fuel consumption, and starting difficulties. Professional cleaning via walnut blasting (cracking walnut shell blowing) costs approximately 600-1000 lei and is recommended every 80,000-100,000 km as a preventive measure.

Importance of oil quality

Turbocharged engines require strict oil standards. The turbocharger operates at very high temperatures (over 700°C on the exhaust side) and very high RPMs (over 100,000 rpm). The oil not only lubricates the turbocharger bearings but also cools it by dissipating heat.

Using lower-quality oil or exceeding oil-change intervals can lead to premature wear of the turbocharger. The cost of a new or remanufactured turbocharger typically ranges from 3,000 to 5,000 lei, plus installation.

Oil maintenance recommendations:

- Use only SAE 5W-20 oil of Ford WSS-M2C948-B specification

- Respect the 15000 km or 1-year oil-change interval

- For severe conditions (urban driving, towing, sporty driving), reduce the interval to 10000 km

- Periodically check oil level, especially on higher-power variants

Minor reported issues

Beyond the issues above, the 1.5 EcoBoost has proven relatively reliable. Some owners have reported:

- Minor oil leaks from the valve cover gasket at high mileage

- Premature ignition coil wear (more common on vehicles using lower-quality fuel)

- Noise from the accessory belt tensioner after around 100000 km

These are minor issues with affordable repair costs and do not significantly affect overall reliability.

Durability and mileage

With proper maintenance and the use of recommended fluids, the 1.5 EcoBoost can reliably exceed 250,000-300,000 km. There are taxi vehicle reports featuring this engine that have surpassed 400,000 km without major engine interventions.

Key longevity factors:

- Observance of service intervals

- Use of quality parts and consumables

- Allowing the engine to warm up before demanding loads

- Avoiding excessive revs when cold

- Fuel quality

Evolution toward Dragon 1.5 EcoBoost

In 2018, Ford introduced a new generation of 1.5 EcoBoost engines based on the three-cylinder architecture – the Dragon 1.5L I-3 EcoBoost. This new generation brings significant improvements:

- Cylinder deactivation for increased efficiency

- Reduced emissions to meet Euro 6d standards

- Improved cooling technology

- Weight reduction of about 8 kg compared to the four-cylinder version

However, the I-4 version continues to be produced and used in certain markets and models, proving that both architectures have their advantages.

Conclusion

The Ford EcoBoost 1.5 I-4 engine remains a solid choice for those seeking a balance between performance, efficiency, and reliability. While it requires attention to fuel quality and oil intervals, along with regular maintenance, this engine has proven to be much more reliable than its 1.6 predecessor.

For prospective used-car buyers equipped with this engine, it is important to check the maintenance history and ensure that services have been performed on time. A careful test drive can reveal injector or valve issues through rough idle or hesitations during acceleration.

With production in Craiova, Romania, this engine also supports the local auto industry, serving as an example of modern technology implemented at a Romanian plant. For car enthusiasts who value an efficient engine with character and sufficient power for daily use, the 1.5 EcoBoost is definitely worth considering.

Photo sources: tu-auto.com, youtube.com, rac.co.uk