- Turbochargers use exhaust energy to compress intake air, boosting power and efficiency

- Popular since the 1980s, delivering more power with the same displacement

- How they work: exhaust drives turbine, compressor boosts air to cylinders

- Maintenance: timely oil changes are crucial for lubrication and cooling; failures costly

Turbochargers are one of the most efficient ways to boost engine performance while delivering remarkable fuel economy. This technology, which has become increasingly popular in the automotive industry, uses energy from exhaust gases to force more air into the engine cylinders, resulting in greater power without increasing displacement.

Although the operating principle may seem complex, understanding how a turbocharger works and knowing the maintenance requirements can significantly extend its life and prevent costly repairs.

History and Evolution of Turbochargers

Turbochargers entered showrooms in the 1980s when Porsche released a sports car equipped with this revolutionary technology. To grab public attention, automakers began labeling vehicles with the “Turbo” badge, creating an aura of prestige and performance around this technology.

From that period to the present, cars equipped with turbochargers have become increasingly sought after. This popularity is justified by the fact that a turbocharger significantly increases engine performance while offering a fuel economy superior to naturally aspirated engines of the same power.

Turbocharger Operating Principle

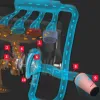

The turbocharger is strategically positioned between the engine and the exhaust system, where it can harvest energy from exhaust gases that would otherwise be wasted through the exhaust pipe.

Main Components

Inside a turbocharger are two wheels mounted on the same shaft:

- Turbocharger turbine wheel (hot side) - captures energy from exhaust gases

- Compressor wheel (cold side) - compresses fresh air and sends it to the engine

Operating Process

- Energy capture: Hot exhaust gases spin the turbine wheel at extreme speeds (up to 300,000 rpm)

- Air compression: Via the common shaft, the compressor wheel is driven and compresses the intake air

- Fueling the engine: The compressed air is directed to the engine cylinders, allowing more fuel to be burned

- Result: A more powerful engine with the same displacement and reduced fuel consumption at partial load

Advantages of Operation

When the driver is cruising and does not need extra power, the turbo operates at minimal load, resulting in a low fuel consumption. When acceleration is required, the turbo system provides the additional power requested.

Turbocharger Maintenance

Although the principle of operation is relatively simple, proper maintenance is crucial to avoid costly failures. A defective turbocharger can cost from a few hundred to several thousand euros, depending on the make and model of the vehicle.

Critical Factors for Turbocharger Longevity

Quality and Timely Oil Change

Motor oil plays a fundamental role in turbocharger operation:

- Lubrication: The turbo shaft spins at extreme speeds and requires constant lubrication

- Cooling: Oil helps dissipate the heat generated by operation at high temperatures

- Cleanliness: Clean oil prevents buildup of residues in internal passages

Oil change at the intervals recommended by the manufacturer is mandatory for keeping the turbo system running. Degraded or insufficient oil can cause:

- Bearing seizure

- Premature shaft wear

- Permanent turbocharger failure

Periodic Service Checks

Experts can detect signs of wear in time and prevent major failures by:

- Checking oil pressure

- Inspecting the intake and exhaust systems

- Testing turbocharger response

- Inspecting engine management systems

Consequences of Neglecting Maintenance

Drivers who do not follow the maintenance schedule risk facing:

- High repair costs: Replacing a turbocharger can cost more than the vehicle’s value in older cars

- Cascading failures: A defective turbocharger can affect other engine components

- Accelerated depreciation: Turbo problems significantly reduce resale value

Repair and Reconstruction Options

When the turbocharger shows wear-related defects, there are alternatives to replacing it with a new unit.

Turbocharger Reconstruction

Reconstruction is an economical alternative that can offer a longer service life at a substantially lower cost than buying a new unit.

Reconstruction Process

-

Complete disassembly

- Demolition with specialized tools

- Identification of carbon traces left by overheated oil

- Evaluation of oil passages

-

Cleaning and inspection

- Measuring inner and outer diameters

- Assessing the condition of each component

- Determining reusable parts

- Identifying components needing replacement (e.g., cracked exhaust housing)

-

Balancing

- Individual balancing of the rotor and turbine

- Balancing the complete assembly

- Checking concentricity and vibrations

-

Reassembly

- Assembly with new gaskets and bearings

- Checking shaft rotation in the oil layer

- Inspecting clearances and sealing

Common Problems and Symptoms

Worn Bearings

Damaged bearings create play at the shaft, allowing oil to pass the seals. The main symptom is blue smoke coming from the exhaust pipe, indicating oil burning in the combustion chamber.

Final Checks

Before putting the system back into operation, verify:

- Oil pressure at all operating regimes

- Proper opening of the exhaust system

- Acceleration response

- Sealing at all connections

Safety Recommendations

Turbo system work requires strict adherence to safety measures:

- Personal protective equipment: gloves, goggles, safety footwear

- Specialized tools: for disassembly and assembly

- Technical knowledge: complex operations should be performed only by specialists

Proper maintenance of the turbocharger not only prolongs its life but also ensures optimal operation of the entire engine system. Investment in preventive maintenance is always cheaper than major repairs, making it a wise choice for any vehicle owner equipped with a turbo.