- Turbochargers compress intake air using exhaust energy to boost power.

- Modern cars use turbos on gasoline and diesel to improve efficiency and enable downsizing.

- Diesel engines compress air before fuel injection; turbo is essential for performance.

- Gasoline engines gain power from turbos, enabling smaller, lighter engines and lower emissions.

A turbocharger is one of the most efficient devices for increasing the power and efficiency of an internal combustion engine. By compressing the air entering the combustion chambers, the turbine enables the engine to burn more fuel and thus produce more power without increasing the engine size. While turbochargers were once considered specialized equipment, today nearly every automaker integrates them into their engine lineup, for both gasoline and diesel.

What is a turbocharger

A turbocharger, also known as a turbo supercharger or simply a turbo, is a forced-induction device driven by a turbine that increases the power of an internal combustion engine by forcing additional compressed air into the combustion chamber. Unlike a naturally aspirated engine that relies solely on atmospheric pressure to push air into the cylinders, the turbine uses exhaust gas energy to compress the intake air.

The operating principle is based on a simple reality: the more air you push into the engine, the more you can burn fuel, and that means more power. The on-board computer of a modern car constantly and precisely calculates the required air–fuel mixture to reach the desired performance. However, each engine is limited by the intake system and the amount of air that can reach the cylinders naturally.

A turbocharger solves this fundamental limitation by compressing the air before it enters the engine. When air is compressed, the oxygen molecules bond more tightly, and the same volume of space contains many more oxygen molecules. This means you can introduce the same amount of air into a smaller space, or more air into the same space - exactly what the turbine provides.

Differences between turbocharged and naturally aspirated engines

One essential difference between a diesel engine with turbocharging and a traditional naturally aspirated gasoline engine is the timing and manner in which air is compressed. In diesel engines, air is compressed before fuel is injected, and the compression ratio is significantly higher than in gasoline engines. For a diesel, the turbocharger becomes practically essential for performance and efficiency, not just an accessory for extra power.

In gasoline engines, the turbine primarily provides a significant increase in power, allowing a smaller engine to produce the same power as a much larger naturally aspirated engine. For example, a 1.5-liter turbo engine can produce the power of a 2.5-liter naturally aspirated engine, while retaining the benefits of a smaller engine: reduced weight, lower fuel consumption in normal operation, and lower emissions.

This improved combustion efficiency allows automakers to practice “downsizing” - reducing engine size while maintaining or even increasing performance. A smaller turbocharged engine weighs less, takes up less space in the engine bay, and can achieve an overall improved fuel economy, especially in urban driving conditions where the turbo is not required at full capacity.

How much additional power does a turbocharger provide

The question of how much power a turbocharger actually adds is complex and depends on many technical factors. In general, a standard turbocharger can offer a power increase between 20 and 40 percent versus an identical naturally aspirated engine. For context, if an atmospheric engine produces 100 CP, the turbocharged version of the same engine can reach 120–140 CP, or even more.

However, the exact power gain varies depending on several factors:

- Size of the turbocharger: Larger turbines can compress more air, but may suffer from turbo lag

- Boost pressure: As the turbine compresses more air (measured in bar or PSI), power rises, but so does mechanical stress on the engine

- Air cooling system: A high-efficiency intercooler cools the compressed air, increasing density and therefore power

- Engine calibration: The ECU must be reprogrammed to correctly manage the extra air and fuel

- Component strength: Pistons, connecting rods, and crankshaft must withstand the added power and pressure

In addition to the raw horsepower, the turbo also significantly improves engine torque (measured in Newton-meters, Nm). This increased torque at mid-to-low RPMs makes the car feel much more powerful in everyday use, delivering better acceleration and overtaking capability.

How a turbocharger works – components and principles

Basic structure

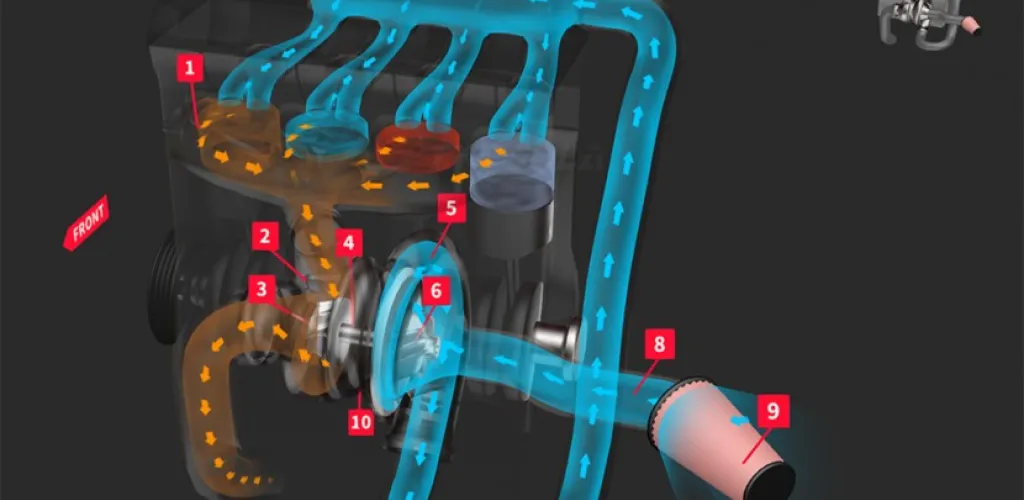

A turbocharger consists of two main halves connected by a forged steel shaft.

-

The turbine side (hot wheel): This half is connected to the exhaust system. Hot exhaust gases, which would otherwise be expelled into the atmosphere, are directed toward the turbine wheel. These gases, moving at very high speeds and temperatures that can exceed 900°C, strike the turbine blades, driving them to rotate at incredible speeds — typically 80,000 to 200,000 rpm, depending on size and type.

-

The compressor side (cold wheel): On the other side of the shaft sits the compressor wheel, which draws air from the atmosphere and compresses it. When the turbine spins the shaft, the compressor wheel spins at the same speed, drawing in air and compressing it before sending it to the engine.

Step-by-step operating process

-

Exhaust gas flow: When the engine runs, pistons push exhaust gases through the exhaust valves. These gases, still very hot and pressurized, are directed toward the turbine rather than going straight to the exhaust pipe.

-

Turbine rotation: The kinetic energy in the exhaust gases hits the turbine blades, causing them to spin at extremely high speeds. The blade shape is designed to extract the maximum energy from the gas flow. After driving the turbine, the gases continue to the exhaust system and catalytic converter.

-

Intake and compression: The turbine rotating the shaft drives the compressor wheel to the same velocity. This rapid rotation creates a vacuum that draws air in from the atmosphere through the air filter. The compressor blades accelerate this air to very high speeds.

-

Air diffusion: The compressor housing is purpose-built to convert the high-velocity, low-pressure air flow into a high-pressure, low-velocity air flow. This process is called diffusion and it is crucial for turbo efficiency. The compressed air becomes denser and hotter.

-

Air cooling (optional but recommended): In most modern systems, the compressed air then passes through an intercooler — a heat exchanger that cools the air. Cooler air is denser than hot air, so cooling further improves efficiency. An intercooler can reduce air temperature by 50–70°C.

-

Entry into the engine: Finally, the compressed and cooled air is forced into the engine cylinders through the throttle body and intake runners. The ECU detects this increased amount of air and injects proportionally more fuel. The enriched air–fuel mixture produces a stronger combustion, generating more power.

Lubrication and cooling system

The turbine shaft spins at speeds so high that friction would destroy bearings within seconds without proper lubrication. For this reason, the turbocharger is connected to the engine’s lubrication system via a dedicated oil feed line. Pressurized oil forms a film around the shaft, allowing it to rotate with minimal metal-to-metal contact.

Additionally, oil helps cool the internal turbine components, which reach extremely high temperatures. Some modern turbines also have cooling from the engine coolant, which improves durability and allows higher boost pressures.

Advantages and technical considerations

Benefits of turbocharging

- Power increase without increasing engine size

- Improved efficiency: smaller turbocharged engines can be more efficient than larger naturally aspirated engines

- Reduced emissions: smaller engines typically emit less under normal conditions

- Increased torque at low revs: useful in traffic and overtaking

- Reduced weight: smaller engine means lighter car and better dynamics

Maintenance considerations

Modern turbochargers are fairly reliable but require adherence to maintenance rules:

- Change oil at recommended intervals with high-quality oil

- Let the engine idle for 30–60 seconds before shutdown after sustained driving

- Use the recommended fuel (correct octane rating)

- Check and replace the air filter as scheduled

Ignoring these aspects can lead to premature turbine wear, and replacing a turbocharger can cost between 5,000 and 15,000 RON, depending on the vehicle model and brand.

In conclusion, the turbocharger is one of the most efficient ways to increase power and efficiency in an internal combustion engine, converting residual energy from exhaust gases into usable extra power. With proper maintenance and correct use, a turbocharger can operate trouble-free for the vehicle’s lifetime.