- The gearbox transmits engine power to wheels, controlling speed and torque.

- All engine power passes through the gearbox, regardless of drivetrain layout.

- The transmission system includes clutch, differential, driveshaft, and planetary gears.

- First gear ratio is about 3.5:1 for starting torque.

The gearbox is one of the fundamental components of any vehicle, responsible for efficiently transmitting power from the engine to the wheels. To understand its role, we can think of the principle of a bicycle — pedaling harder up a hill in low gears, or easier on flat ground with high gears.

In driving tests, the question ‘What is the role of the gearbox?’ is common, and the following answer options are all correct: it provides power to the wheels, allows reverse without reversing the direction of the engine’s rotation, and enables stationary with the engine running.

Transmission system and the gearbox’s role

A car’s transmission uses the gearbox to transform the power generated by the engine into rotations of the wheels, with the aim of moving the entire vehicle. The process starts with fuel in the tank, which is drawn by the fuel pump and injected into the cylinders through injectors.

The engine mixes the fuel with air through the intake system, and through a spark (or compression in diesel engines) a small explosion occurs that drives the piston. Each piston is connected to a crankshaft, so named for its distinctive shape, which takes the force and converts it into rotational motion.

The rotational motion of the crankshaft reaches the flywheel — a metal disk with a single- or dual-mass construction — which captures this motion and transfers it to the gearbox via the clutch, specifically the clutch plate.

Difference between the transmission system and the gearbox

It’s important to clarify that the transmission system is not limited to the gearbox. The gearbox is part of a larger, more complex system that includes the clutch, differential, driveshaft, and planetary gears. All these components work together to ensure efficient power transmission.

How the gearbox works: principles and components

All the power from the engine passes through the gearbox before reaching the wheels, regardless of drivetrain type (front-, rear-, or all-wheel drive).

The basic role of the gearbox is to control the speed and torque transmitted to the wheels, allowing adaptation to traffic conditions.

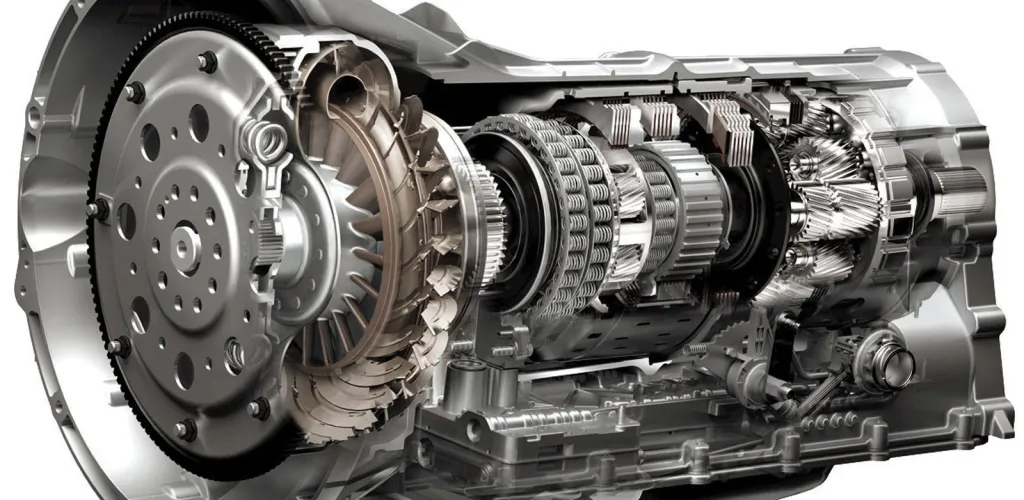

Internal structure

A standard gearbox has two main shafts:

- Main shaft - receives energy (rotational motion) from the flywheel

- Secondary shaft - transmits processed power to the wheels

These two shafts are equipped with gears of different sizes, which create specific ratios for each gear.

Gear ratios and gear wheel operation

The gearbox must adapt to two different requirements:

- At low speeds - requires more torque (e.g., when starting from a standstill in first gear)

- At high speeds - with inertia, does not require as much torque to continue moving

For gear 1, the pinion on the main shaft (about 35 teeth) meshes with a much larger pinion on the secondary shaft (55 teeth), providing a ratio of approximately 3.5:1.

Explanation of the ratio: While the pinion on the main shaft makes 3.5 rotations, the one on the secondary shaft turns only once, resulting in higher output torque. Thus, at the wheels, the gearbox provides an output speed 3.5 times slower than the engine speed, but with significantly higher torque.

Gear-shifting mechanism

The gear lever actuates one or more forks that move gears between positions, selecting the predetermined configuration set by the manufacturer for each gear. As you shift into higher gears, the engaged gears become closer in the number of teeth and size, providing a smooth journey and linear acceleration.

In gears where the ratio falls below 1:1, the pinion on the secondary shaft has fewer teeth than the main, turning faster and providing a stable cruising speed, helping reduce fuel consumption.

The impact of gear selection on fuel consumption

The connection between gear and fuel consumption is direct. The car’s horsepower is determined by torque, and fuel consumption is linked to the power/torque produced by the engine.

To move a 1.5-ton car from a standstill requires more power (torque) than keeping it at a constant cruising speed of 130 km/h on the highway. For this reason, the highest fuel consumption is recorded in urban traffic, where we use gears with high ratios to start from a standstill and accelerate.

Misconceptions about power and consumption

There are misconceptions about cars with a lot of horsepower. A 1.8L turbo gasoline engine with 220 hp can consume as much as a 3.0L biturbo gasoline engine with 500 hp when both engines are used in the same driving conditions. The difference lies in how they are used and the specific demands of the moment.

Practical example of gear ratios

- Gear 1: 3.78:1

- Gear 2: 2.12:1

- Gear 3: 1.36:1

- Gear 4: 0.97:1

- Gear 5: 0.77:1

- Gear 6: 0.65:1

- Reverse: 3.25:1

Note that the reverse gear has a ratio close to that of gear 1, because we need to start from a standstill and thus require greater torque.

Types of modern gearboxes

There are many names and types of gearboxes, especially when it comes to automatics:

- Sequential gearboxes

- Hydramatic gearboxes (older generation automatics)

- DSG (Direct Shift Gearbox) — highly regarded at Volkswagen

- CVT (Continuously Variable Transmission) — popular at Toyota

- Torque-converter gearboxes

- Robotic gearboxes

Differences in cost and maintenance

All gearboxes share the same fundamental role — transmitting power from the engine to the wheels — yet they do not cost or operate the same. An automatic gearbox will always be more expensive than a manual one, due to the complexity of the components.

Modern automatics come with additional features:

- Two clutches that operate directly in oil

- Mechatronic control (absent in manual gearboxes)

- Torque converter (specific to automatic gearboxes)

- Advanced electronic control systems

Gearbox maintenance

Maintenance costs vary by brand and model. However, whether manual or automatic, it is essential to remember that an oil change is necessary in the gearbox periodically.

The concept of ‘Lifetime Oil’ does not exist in reality and is merely a marketing scheme used by manufacturers. The gearbox oil degrades over time and needs replacement to ensure optimal operation and longevity of the components.

Understanding the gearbox’s role and operation can help you make more informed vehicle-buying decisions and keep the transmission in optimal condition through proper maintenance.