- Forms combustion chamber and manages intake, exhaust, coolant, and oil circuits.

- Types include one-piece heads, individual per cylinder, and dual heads for V engines.

- Contains timing system parts, injectors, glow plugs, cooling and oil channels.

- Aluminum alloy heads offer high thermal conductivity and lighter weight.

The cylinder head is one of the most critical components of an internal combustion engine, forming the upper half of the engine block. This complex and multifunctional part plays a key role in the combustion process and in the proper operation of the entire engine assembly. Together with the engine block and piston, the cylinder head forms the combustion chamber where combustion takes place, while simultaneously managing four separate circuits: intake gases, exhaust gases, coolant, and engine oil.

For auto enthusiasts it is important to understand that the correct term is cylinder head (plural: cylinder heads), not “chinhead” as it is often mispronounced. The word comes from the French “culasse” and has been adapted into Romanian in various forms, but the correct variant remains cylinder head.

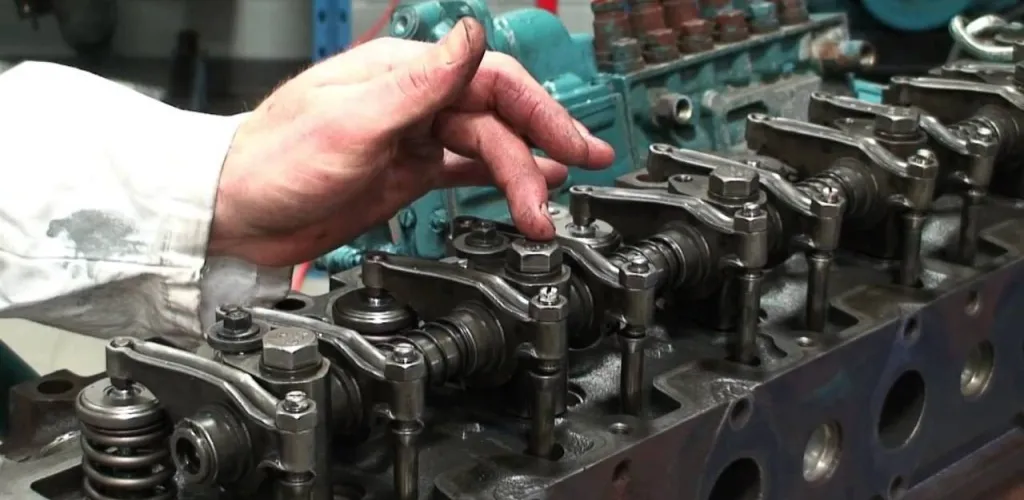

Structure and types of cylinder heads

The cylinder head is the engine component mounted on the top part of the engine block, above the cylinders, and it serves to “close” the combustion chamber. This component must withstand extreme pressures and temperatures up to 2000°C inside the combustion chamber.

Types of cylinder heads by configuration

- One-piece heads: made from a single piece that covers all cylinders — the most common variant on mass-produced cars

- Individual heads: one small head per cylinder — used in competition engines for easier access to each cylinder

- Dual heads: in V engines, where there are usually two cylinder heads, one for each bank of cylinders

Integrated components in the cylinder head

The cylinder head is a multifunctional component with a contorted shape, containing:

- Part of the timing system (valves, springs, camshafts, tappets, lifters)

- Fuel injectors for direct-injection engines

- Glow plugs (in diesel engines)

- The complex cooling circuit with internal channels

- Channels for engine oil circulation

- The combustion chamber with an optimized shape for efficient combustion

Technical specifications and construction materials

Because of its multiple roles, the cylinder head is subjected to extreme mechanical and thermal stresses. High tensions and pressures act unevenly on it, creating significant design challenges.

Performance specifications

A modern cylinder head must meet the following technical requirements:

- Very high mechanical rigidity to withstand combustion pressures of 15-20 bar in naturally aspirated engines and up to 40-50 bar in turbocharged engines

- High thermal resistance to temperatures up to 2000°C in the combustion chamber

- Perfect sealing for coolant, gases and oil

- Uniform temperature distribution for optimal cooling and to avoid hot spots

- Low mass for engine efficiency and reduced inertia

- Optimized combustion chamber shape for maximum performance and reduced emissions

Materials and modern technologies

Aluminum alloy cylinder heads: Used on most modern cars, offering:

- Excellent thermal conductivity (around 200 W/mK)

- 40-50% lighter than cast iron

- Easy machinability for complex shapes

- Production by low-pressure casting for high precision

- Coefficient of thermal expansion similar to aluminum engine blocks

Cast iron cylinder heads: Still used on heavy-duty commercial vehicles and industrial engines, offering:

- Superior hardness and wear resistance

- High mechanical strength under extreme loads

- Lower production costs

- Excellent dimensional stability at high temperatures

For aluminum heads, the valves do not seat directly on the base material; they sit on special seats made of iron or stainless steel, which better withstand the mechanical and thermal stresses generated by repetitive opening and closing.

Correct mounting and torquing procedure

Mounting the cylinder head is an extremely precise operation that requires following strict procedures to avoid deformation and ensure perfect sealing.

Head bolt tightening sequence

Head bolts are always tightened in an X-cross pattern — if you tighten a bolt in one corner, the next should be the bolt in the opposite corner. This is the standard order for most engines:

- First tightening: 40 Nm with the torque wrench for initial seating

- Clamp tightening: 60 Nm for even seating

- Loosening: half a turn on all bolts to relieve stresses

- Second tightening: 50 Nm for pre-load

- Final tightening: a quarter-turn twice for final load

Important: Cylinder head bolts are single-use (TTY – Torque To Yield) and must not be reused after full torque, as they are stretched beyond the elastic limit.

Checks before mounting

- Thorough cleaning of the contact surface

- Flatness check with a straightedge and a feeler gauge

- Inspect the condition of the new bolts

- Check that the gasket does not protrude beyond the edges

- Lightly lubricate the bolt threads

Integrated cooling system

Inside the cylinder head are complex channels through which the coolant circulates. This cooling is crucial because temperatures in the combustion chamber reach 1800-2000°C, and near the exhaust valves they can reach 700-800°C.

Cooling channel design

The cooling channels in the cylinder head are designed to:

- Prioritize cooling of the exhaust valve areas

- Distribute temperature evenly to avoid thermal stresses

- Provide optimal flow for efficient heat transfer

- Eliminate air pockets through an inclined design

- Offer frost protection at low temperatures

Valve configuration and thermal management

The position of the valves in the cylinder head considers:

- The number of cylinders and the firing order for thermal distribution

- Avoiding exhaust valve positions near the separator walls

- Different valve sizes: intake valves are larger for optimal filling

- Valve angles for efficient flow and controlled turbulence

In naturally aspirated engines, intake valves have diameters 15-20% larger because air intake is more challenging than the exhaust gases, which are under pressure.

Sealing and cylinder head gasket

The cylinder head manages four distinct circuits that must not mix:

- Intake gases (negative pressure)

- Exhaust gases (positive pressure, high temperature)

- Coolant (1-2 bar, 90-110°C)

- Engine oil (2-6 bar, 80-120°C)

Perfect sealing between these circuits is ensured by the cylinder head gasket, which must withstand extreme pressures and temperatures for tens of thousands of kilometers.

Types of modern gaskets

- Multi-layer steel (MLS) gaskets: with 3-5 layers of stainless steel

- Composite gaskets: with metallic inserts and elastic material

- Ceramic-coated gaskets: for high-performance engines

Symptoms of sealing problems

- White smoke from exhaust: coolant in cylinders — most visible on cold starts

- Blue smoke: oil in the combustion chamber — visible on acceleration

- Power loss: compression leaks between cylinders

- Overheating: issues with coolant circulation

- Oil emulsion: oil-coolant mixture visible on the valve cover

- Air bubbles in the expansion tank: combustion gases in the cooling system

Repairs and reconditioning procedures

Specialized service operations

Inspection and repair of the contact surface:

- Planing: removal of deformed material (maximum 0.1-0.2 mm)

- Flatness measurement: tolerance of 0.05 mm across the entire surface

- Crack inspection: using penetrant liquids or pressure methods

Reconditioning the valve system:

- Resurfacing of valve seats: for new valves with the correct angle (45° or 30°)

- Valve lapping: for perfect sealing

- Gland/guide replacement: when wear exceeds permissible limits (0.1-0.15 mm)

- Spring checks: for correct force and length

Timing system:

- Tappet configuration: on models without hydraulic self-adjustment

- Camshafts inspection: for wear and ovality

- Tension checks: for proper operation

DIY valve seal test

You can check valve sealing at home with a simple test:

- Thoroughly clean the cylinder head of any residues

- Turn it upside down with the valves facing up

- Pour gasoline into the combustion chambers

- Wait 10-15 minutes

- Check if gasoline leaks through the intake/exhaust ports

If gasoline leaks, the valves no longer seal and require reconditioning.

Preventive maintenance and protective measures

Recommendations for maximum longevity

Cooling system:

- Do not use only water in the cooling system — small channels can clog from limescale and rust deposits

- Change the coolant at the recommended intervals (2-5 years)

- Check the antifreeze concentration: 50-60% for optimal protection

- Check system pressure with a specialized tester annually

Ongoing monitoring:

- Monitor engine temperature on the dashboard continuously

- Periodically inspect cooling hoses for cracks

- Check the coolant level weekly

- Observe the color of exhaust smoke

Warning signs requiring immediate shutdown:

- Temperature above 110°C

- Abundant white smoke from the exhaust

- Major coolant leaks

- Metallic noises from the engine

Repair costs and replacement parts

Repairing a cylinder head can cost between 800-2500 lei depending on:

- The engine’s complexity (number of valves)

- The head material (aluminum or cast iron)

- The degree of wear

- The need to replace components (valves, guides, springs)

Conclusion

The cylinder head is the heart of the engine’s combustion system, a fundamental component whose complexity and importance should not be underestimated. Given the extreme stresses it endures — pressures of tens of bars and temperatures of thousands of degrees — preventive maintenance and correct mounting procedures are essential for optimal engine performance and longevity.

Understanding how the cylinder head works helps you appreciate the complexity of modern engines and make informed decisions about vehicle maintenance. At any sign of trouble — overheating, colored exhaust smoke, or loss of power — turning to an experienced, specialized workshop is the safest option to avoid costly repairs that can reach up to half the car’s value.

Investing in preventive maintenance of the cooling system and respecting service intervals can significantly extend the life of the cylinder head and the entire engine.

Photo sources: manciniracing.com, indiamart.com, carid.com, youtube.com, gumtree.co.za