- P0155 signals a heater circuit fault in Bank 2 Sensor 2 O2 sensor.

- Symptoms: poor performance, reduced fuel economy, idle instability, and check engine light.

- Common causes: faulty sensor or wiring, fuel pressure issues, fuses, PCM, or grounding.

- Diagnostics focus on wiring and resistance, with heater resistance about 8 ohms (+/-10%).

The P0155 error code indicates a fault in the heated oxygen sensor (HO2S) circuit for cylinder 2, sensor 2 (B2S2). This issue can affect engine performance and fuel economy, so diagnosing and repairing it promptly is important to maintain the efficiency of the engine-management system.

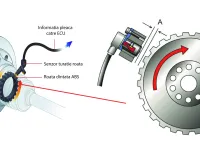

The B2S2 oxygen sensor is located behind the catalyst on cylinder 2 and monitors the efficiency of exhaust gas conversion. The built-in heater allows the sensor to operate optimally soon after the engine starts.

What the P0155 code means

Nomenclature explanation:

- B2 represents cylinder 2 of the engine block

- S2 indicates that the fault is in sensor 2 or the downstream sensor (behind the catalytic converter)

Code-triggering parameters

An universal heater resistance of about 8 ohms is normal for this circuit. Variations greater than 10% in either direction will result in a stored code and a check engine light.

Specific triggering conditions:

- The heater circuit voltage overlaps with the battery voltage, with a variance of 10%

- The engine running in closed-loop

- Oxygen sensor readings remaining constant for an extended period (usually more than 8 seconds)

Symptoms of the P0155 code

The following symptoms may indicate the presence of this fault:

- Poor engine performance - irregular accelerations, unstable idle

- Decreased fuel efficiency - increased fuel consumption

- Black smoke from the exhaust pipe - incomplete combustion of the air-fuel mixture

- Check Engine light on on the dashboard

Common causes of the P0155 code

Possible causes include:

- Faulty oxygen sensor - the most common reason

- Faulty electrical connector at the oxygen sensor

- Damaged or shorted wiring in the oxygen sensor circuit

- Low or excessive fuel pressure

- Faulty PCM (less common fault)

- Blown fuses in the power circuit

- Grounding problems in the electrical circuit

Common diagnostic mistakes

Technicians often resort to replacing oxygen sensors when engine running issues occur, without first checking the electrical circuits. Incorrect replacement of the oxygen sensor is also a frequent possibility.

Common diagnostic mistakes:

- Replacing the sensor without checking wiring

- Neglecting circuit resistance testing

- Ignoring power supply issues

Diagnostic process for P0155

Understanding how the system works

For the engine to run correctly, a 14:7 air-fuel mixture is required. The PCM controls fuel delivery, ignition timing, and the fuel injector pulse.

The PCM collects input signals from various sensors to calculate the fuel delivery strategy. The heated oxygen sensor is one of the most important sensors, used to detect the oxygen levels in the exhaust system.

The oxygen sensor heater function

The heater portion of the oxygen sensor is a dedicated electrical circuit solely for heating the oxygen sensors. Most oxygen sensors in vehicles equipped with OBD-II are heated, each with its own built-in heater.

Advantages of heating:

- Allows the sensor to become operational sooner

- Reduces emissions during cold starts

- Shortens the time required to enter closed-loop mode

Tools needed for diagnostics

- OBD-II scanner or code reader

- Digital multimeter for measuring voltage and resistance

- Manufacturer service manual

- Oscilloscope (optional, for advanced analyses)

Detailed diagnostic steps

1. Initial visual inspection

Begin diagnostics by visually inspecting all wiring and connectors:

- Look for physical damage, corrosion, or disconnections

- Inspect circuit fuses

- Examine wiring for signs of wear or cuts

2. Reading and analyzing codes

Connect the scanner to the diagnostic port and:

- Record all stored codes

- Note the freeze-frame data

- Clear the codes and check if they reappear

3. Testing the oxygen sensor

Visual check of the sensor:

- Remove the sensor if accessible

- Check for signs of residues or discoloration

- Check the physical condition of the heater element

Electrical testing:

- Measure heater resistance (normal around 8 ohms)

- Check circuit continuity

- Test the power supply (12.6-13.8V)

4. Sensor signal analysis

The heated oxygen sensor (pre-catalyst) should fluctuate consistently between roughly 100-900 millivolts once the engine reaches normal operating temperature and the PCM enters closed-loop operation.

5. Testing system circuits

If the sensor is functioning correctly:

- Test the circuits for resistance and continuity

- Check the power supply

- Check the ground circuit

- Compare results with the manufacturer specifications

Repairs and solutions

Common repairs

- Replacing the oxygen sensor - if tests confirm the fault

- Repairing or replacing faulty wiring

- Cleaning or replacing corroded connectors

- Replacing burnt fuses in the power circuit

Post-repair verification

After any repair:

- Clear the error codes

- Start the engine and allow it to warm up

- Perform a road test to confirm the repair

- Re-check with the scanner to ensure codes do not reappear

Special cases

If all circuits and components are in good condition, a PCM fault may be possible, though rare. In this case:

- Check all PCM connections

- Consult a specialist for PCM reprogramming

- Consider module replacement only as a last resort

Preventing future problems

To avoid recurrence of code P0155:

- Perform regular exhaust-system maintenance

- Use high-quality fuel to prevent deposits

- Periodically check oxygen sensor condition

- Replace sensors according to the recommended maintenance schedule

Estimated repair costs

Costs can vary by make and model:

- New oxygen sensor: 200-600 RON

- Diagnostic labor: 100-300 RON

- Wiring repairs: 150-500 RON

- PCM replacement: 2000-5000 RON (rarely required)

Correct diagnosis is essential to avoid unnecessary and costly replacements. A qualified technician can quickly identify the real cause and perform the necessary repair efficiently.