- It pressurizes diesel to inject into the combustion chamber.

- It operates via intake and compression strokes with cam-driven or spring-driven designs.

- Common Rail pumps: 300–1000 bar (up to 2000+); PD pumps: lower pressure.

- Surges, power loss, vibrations; bearing flaking and metal chips contaminate injectors.

Fuel injection pumps are among the most complex and critical components of a diesel engine. Without this crucial part, the engine cannot operate, as it provides the pressure needed to push fuel into the combustion chamber. While every diesel driver has heard of the fuel injection pump, few truly understand how it works and the problems it can encounter.

This article explains what the pump does, how it operates, common failure modes, and how to protect or recondition it.

What is the fuel injection pump and how it works

Operating principle

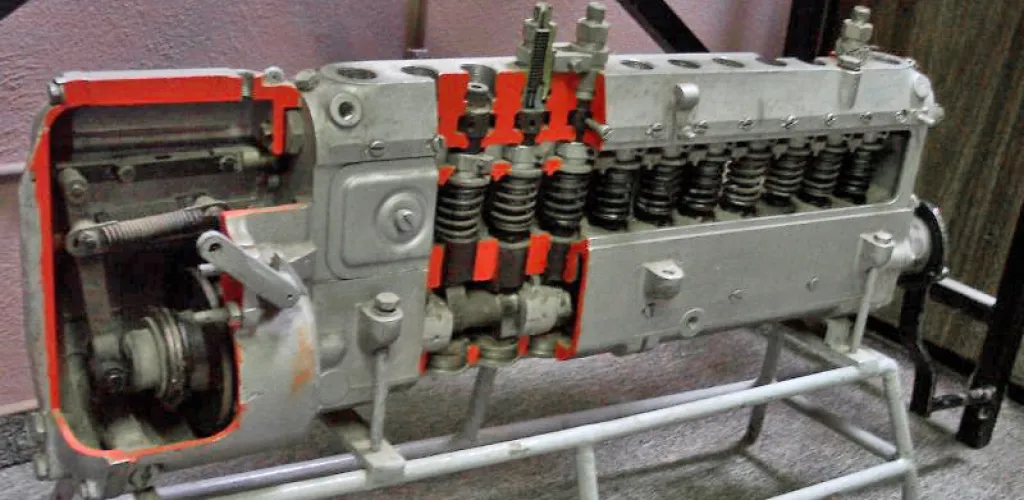

Inside the fuel injection pump there are:

- A small piston connected directly to the drive shaft

- A set of control valves

- A shaft driven by the timing belt or timing chain

The operating principle consists of two piston strokes:

- Intake stroke - the piston draws diesel from the reservoir

- Compression stroke - the piston pushes the diesel under pressure into the injection system

Piston drive types

Rigid cam-driven:

- The piston is driven by a cam with a specific profile

- It enables more precise fuel injection control

- The most widespread system on the market

Spring-driven:

- The piston is driven by a spring

- Injection is no longer dependent on engine speed

- Better fuel metering

- Less precise control of injection

Types of fuel injection pumps according to the fueling system

Common Rail systems

In engines equipped with a common rail injection system, the injection pump (also called the high-pressure pump) operates at extremely high pressures:

- Normal pressures: 300-1000 bar

- Maximum pressures: up to 2000+ bar in modern engines

PD (pump-nozzle) systems

In PD engines, the injection pump operates at lower pressures, because the final injection pressure is produced by individual injectors for each cylinder.

Symptoms of a defective fuel injection pump

Main symptoms

High-speed problems:

- The engine starts to surge and no longer runs smoothly

- Loss of power at constant highway speeds

- The car runs normally for 15-20 km, then starts to stumble for 1-2 km

Excessive vibrations:

- Caused by insufficient pressure in the injection system

- The engine no longer receives fuel at the correct pressure

- Intermittent engine trembling

High-pressure pump-specific issues

Bearing flaking:

- The metallic material (usually aluminum) ends up in the injection system

- This “chip” can block injectors

- Often caused by poor-quality fuels

Production of chips:

- Particulate metal contaminate the entire system

- Can damage injectors and other components

- Requires thorough cleaning of the system

Solutions for a faulty injection pump

Option 1: New pump

Advantages:

- Full warranty

- Optimum performance

Disadvantages:

- Very high cost (hundreds to thousands of euros)

- Not always justified for older cars

Option 2: Used pump

Advantages:

- Affordable price (100-200 EUR)

- Wide availability at breakers

Disadvantages:

- High risk of future failure

- No long-term warranty

- Possibility to produce chips after installation

Option 3: Reconditioning (the most recommended)

Advantages:

- Excellent price-quality ratio

- Workshop warranty

- Performance close to a new pump

Costs:

- Simple pumps: 250-300 lei

- Complex pumps: 1500-2000 lei

Additional requirements:

- Reconditioning of injectors at the same time

- Cleaning of the rail and fuel lines

- Cleaning of the tank and fuel pathway

How to protect your injection pump

Correct fueling practices

Avoid running the tank dry:

- Never drive on the “reserve”

- Always keep at least 1/4 of the tank full

- Impurities settle at the bottom of the tank

Responsible fueling:

- Use the same trusted supplier

- Avoid newly opened or unsafe gas stations

- Prefer premium fuels or additives

- Do not fuel from unknown cans or drums

Maintenance of the fuel filter

Importance of the filter:

- Use only high-quality fuel filters

- Change the filter according to the maintenance schedule

- Cheap filters can let grime through or degrade

Consequences of neglect:

- Impurities in the injection system

- Premature pump wear

- Injector blockage

Risks to avoid

Questionable fuels:

- Red-dyed diesel (industrial diesel)

- Watered-down blends

- Cheap fuels from unknown sources

Signs of contaminated fuel:

- Unusual color

- Suspicious odor

- Price well below the market average

Choosing a reconditioning service

Selection criteria

Experience in the field:

- Track record of working with injection pumps

- Specialized equipment (test benches/measurement rigs)

- References and recommendations

Warning signs:

- “Specialists” without experience

- Suspiciously low prices

- Lack of professional equipment

- Refusal to provide warranty

What not to do:

- Don’t try to dismantle the pump at home

- Don’t rely on inexperienced “handymen”

- Don’t choose based on the lowest price

The professional reconditioning process

Main steps:

- Testing the pump on a specialized test bench

- Complete disassembly

- Replacing worn parts

- Calibration and adjustment

- Final testing

Warranties offered:

- Reconditioning warranty (usually 12-24 months)

- Performance tests

- Guaranteed technical specifications

The fuel injection pump is the heart of the diesel fueling system. Understanding how it works and adopting proper maintenance practices can significantly extend its life and avoid costly repair bills.