- FSI injects fuel directly into the combustion chamber at 30-110 bar

- Direct injection cools the combustion chamber via fuel evaporation

- Higher compression improves efficiency and performance

- Two-stage intake boosts torque up to 15% at low revs

FSI technology (Fuel Stratified Injection) represents a significant evolution in internal combustion engines, having been widely adopted by manufacturers such as Volkswagen and Audi. This direct injection technology brings numerous benefits in terms of performance, fuel efficiency, and emissions.

What FSI Means and How It Works

FSI stands for Fuel Stratified Injection and marks a fundamental difference from traditional injection systems. Unlike the previous model, when the fuel/air mixture was formed in the intake manifold, with FSI fuel injection takes place directly in the cylinder bore, inside the combustion chamber.

FSI injectors calculate the volume of fuel with millisecond precision and can inject fuel at pressures between 30 and 110 bar. This high pressure means the fuel does not ‘flow’ into the cylinder, but is sprayed inside, creating a very fine atomization of the fuel droplets.

Technical Advantages of FSI Technology

Cooling of the combustion chamber

An important benefit of direct injection is cooling of the cylinder walls. When the fuel is injected directly into the combustion chamber, its evaporation extracts heat from the metal of the cylinder, helping to maintain an optimal operating temperature.

Detonation prevention

Detonation is extremely harmful for any engine and can lead to high repair costs, causing damage to pistons, piston rings, and even the engine block.

Higher compression

FSI engines benefit from a greater geometric compression than conventional injection systems. This increased compression translates to superior thermal efficiency and improved performance.

Two-stage Intelligent Air Intake System

The intake manifold of FSI engines features a significant innovation—a system that operates in two distinct stages:

First stage — Short path

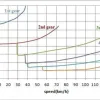

The first stage uses a shorter intake path, aiding the engine at high revs and contributing to higher performance. This optimized path reduces resistance to air flow and allows more efficient filling of the cylinders.

Second stage — Long path

The second stage uses a longer intake path, activated when the engine runs at low revs or under sub-maximum load. In this configuration, torque can increase by up to 15%, improving throttle response in urban driving.

Intelligent Airflow Control

With the help of an additional air valve, the airflow inside the intake manifold can be adjusted by the on-board computer according to the engine’s needs:

- During relaxed driving: More air enters the engine to improve fuel economy and reduce emissions

- During strong accelerations: Air is drawn into the engine with minimal losses, ensuring that the engine power and torque are at maximum

Evolution of Technology — Valve Control

The latest generation of Audi V6 FSI engines is equipped with an intelligent intake valve control system. The valves open differently depending on engine speed, simultaneously delivering fuel economy and maximum power.

Comparison with Other Technologies

The current FSI system shows similarities with Honda’s VTEC system, which also controls intelligent valves according to engine speed, adjusting the parameters of the four-stroke cycle to optimize performance.

Conclusion

FSI technology represents a mature technical solution that combines high performance with fuel efficiency and lower emissions. Through direct fuel injection and intelligent intake and valve control systems, FSI engines offer a superior driving experience and reduced operating costs.