- Diesel injection systems include single-point, multi-point, pump-injector, and common-rail designs.

- Pump-injector benefits: reliability and simple maintenance; drawbacks: limited ECU control and fixed pressure.

- Common-rail benefits: lower fuel consumption, reduced NOx, precise control; drawbacks: complexity, cost.

- Common injector faults include loss of spring elasticity causing premature injection.

Fuel injectors are precision components essential for the correct operation of the engine, responsible for spraying fuel into the cylinders at the correct pressure and timing. The evolution of these components has been remarkable, moving from carburetors to increasingly sophisticated electronic injection systems.

Until the 1990s, diesel engines operated with mechanical injection systems, while gasoline engines used carburetors. With technological progress, carburetors were replaced by electronic injection systems, offering higher efficiency and lower emissions.

Types of injection systems

- Single-point electronic injection – one injector for all cylinders

- Multi-point injection – one injector per cylinder

- Pump-injector system – the injector also acts as a high-pressure pump

- Common-rail system – a common rail feeds all injectors

In turbocharged cars, injection systems operate at very high pressures, even 500–1000 bar in modern diesel engines.

Popular injection systems

The most widespread systems are:

- Bosch, Delphi, and VDO – electronic systems

- Bosch CR, Delphi CR, Siemens CR – common-rail systems

- Denso – high-performance systems

How the pump-injector system works

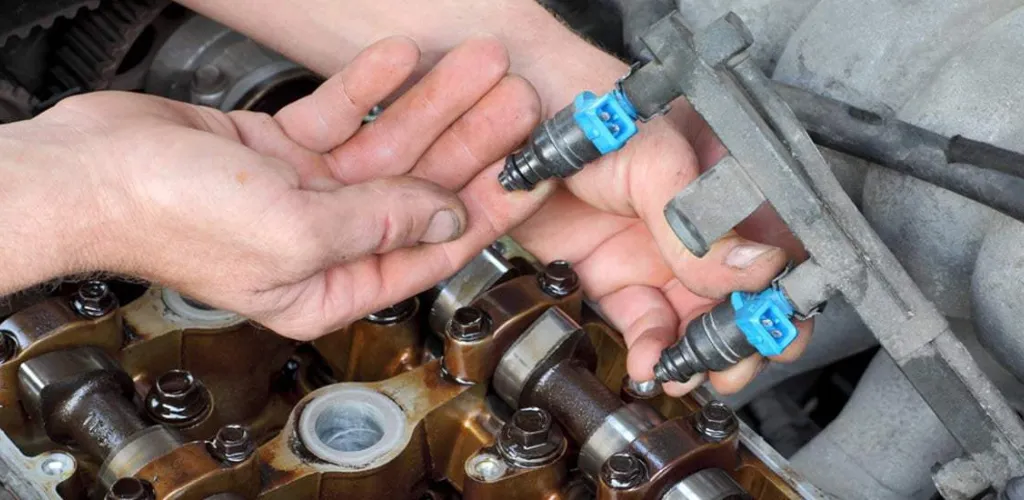

The pump-injector system is an ingenious technical solution in which each injector both injects fuel and acts as a high-pressure pump. These components work like small syringes with springs that atomize diesel when actuated by the camshaft.

Advantages of the pump-injector system:

- High long-term reliability

- Robust construction

- Simpler maintenance

- Resistance to high mileage

Disadvantages of the system:

- Injection pressure is constant regardless of engine speed

- Lower efficiency at high revs

- Higher NOx emissions

- Limited control from the ECU

The common-rail system and its advantages

The common-rail system uses a common rail to feed all injectors at high pressure simultaneously. Diesel is drawn from the tank by a low-pressure pump, then compressed by a high-pressure pump and distributed evenly to all injectors.

Advantages of the common-rail:

- Lower fuel consumption

- Reduced NOx emissions

- Superior performance

- Precise injection control

- ECU programming flexibility

Disadvantages of the system:

- High technical complexity

- Requirement for perfect synchronization

- Reduced long-term reliability

- Sensitivity to fuel quality

- Higher maintenance costs

The aluminum high-pressure pump is vulnerable to poor-quality diesel, producing metal particles that can clog the entire injection system.

Common injector faults

Injectors can fail in several ways, with each failure type manifesting specific symptoms:

1. Loss of spring elasticity

Springs lose elasticity, and the opening pressure of the injectors decreases. This problem causes:

- Premature fuel injection

- Reduced injection pressure

- Insufficient fuel quantity

- Decreased engine efficiency

2. Misalignment or nozzle clogging

Carbon deposits from burning low-quality fuel can:

- Alter the direction of the fuel jets

- Cause incomplete combustion

- Reduce engine performance

- Increase pollutant emissions

3. Electronic system failures

In Delphi injection, the return valve or control valve can fail, leading to:

- Loss of control over the fuel return

- Fuel leakage

- Affects system pressure

- Reduces injection efficiency

Why injectors fail

The main causes of injector failure in Romania are related to specific usage conditions:

- Predominantly urban driving – low speeds, short distances

- Frequent starts and stops – thermal stress on components

- Cold engine for long periods – incomplete combustion

- Constant low RPM – carbon deposits

- Poor fuel quality – impurities and particles

For diesel engines, if injectors are not exercised periodically at high revs, carbon builds up and gradually clogs them.

Symptoms of a faulty injector

Early recognition of symptoms can prevent costly damage:

General symptoms:

- Drastic loss of engine power

- Appearance of black smoke in the exhaust

- Difficult starting when cold

- Illumination of the