- High-pressure injectors (up to 2000 bar) require preventive fuel system maintenance.

- Fuel additives help clean injectors and protect the system when added at 10,000 km.

- Let engine idle 1-2 minutes after aggressive driving to prevent deposits.

- Choose fueling stations with high volume, good reputation, and modern filters.

Fuel system is one of the vital components of any internal combustion engine. The performance and condition of this system directly affect the engine’s power, fuel economy, and reliability. A compromised fuel system can cause major, costly problems, so preventive maintenance is essential.

Fuel quality and proper maintenance of the fuel system components are key factors for the long-term performance of the engine. Contaminated or low-quality fuel can cause injector clogging and damage other critical components.

Why fuel system maintenance is crucial

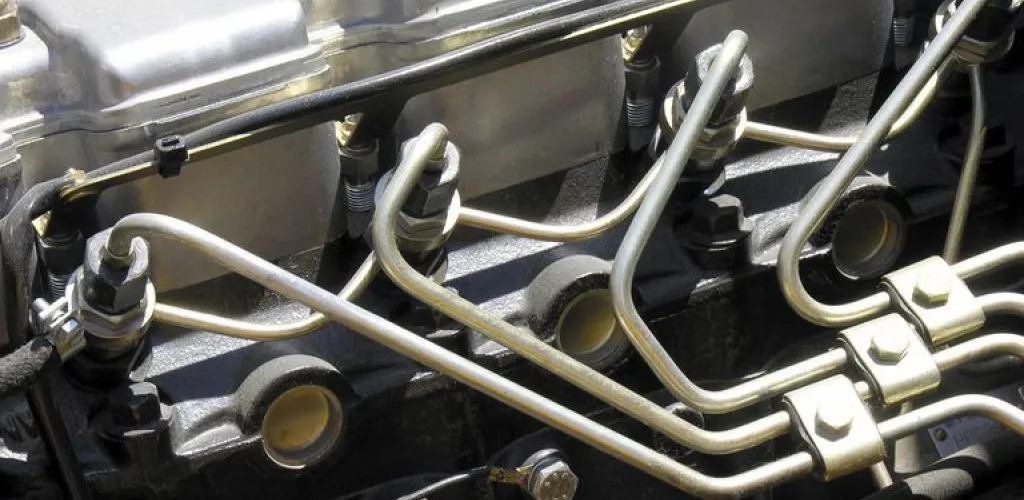

Modern engines are equipped with high-pressure injection systems that operate with extremely tight tolerances. Injectors are precision components that spray fuel into the combustion chamber at pressures that can reach up to 2000 bar in modern diesel engines.

These sensitive components are constantly exposed to:

- Fuel of variable quality

- Exhaust gases resulting from the combustion process

- Extreme temperatures in the combustion chamber

- Vibrations and high pressures

Over time, these adverse conditions lead to the formation of carbon deposits and other residues that can compromise injector performance.

How to maintain the fuel system

Using fuel additives

An efficient and affordable way to keep injectors clean is periodic use of special additives. These are added to the tank at around 10,000 kilometers and mix with a full tank of fuel.

Quality additives contain:

- Detergents that dissolve existing deposits

- Cleaning agents for the fuel system

- Stabilizers that improve fuel quality

- Corrosion inhibitors for protecting metal components

Driving practices to protect the system

An often overlooked aspect is how you shut off the engine after aggressive driving. When you shut off the engine abruptly after dynamic driving, the engine remains overheated and inside the cylinders residues of fuel and burnt gases persist.

These residues, due to the high temperature, carbonize and deposit on all components near the combustion chamber, including the injectors. To avoid this situation:

- Let the engine idle for 1-2 minutes after aggressive driving

- Avoid abrupt accelerations before stopping the engine

- Allow the cooling system to stabilize the temperature

Choosing fueling stations

Fuel quality varies significantly between suppliers. Constant fueling at stations with a poor reputation can introduce impurities into the system that accelerate wear on components.

Criteria for choosing a fueling station:

- High sales volume (fresh fuel)

- Provider reputation

- Presence of filters and modern cleaning systems

- Avoid stations with suspiciously low prices

How to clean fuel system components

Professional injector cleaning

When carbon deposits are already present, professional cleaning becomes necessary. Specialized services use ultrasonic equipment and specific chemical solutions to restore injectors to original specifications.

The professional cleaning process includes:

- Removing injectors from the engine

- Stand testing of operating parameters

- Ultrasonic cleaning in specialized benches

- Replacing worn filters and gaskets

- Re-testing and final calibration

Costs for this operation range from 200-500 RON per injector, depending on system complexity and contamination level.

Fuel tank maintenance

The tank can accumulate sediments, water, and other contaminants that affect fuel quality. Cleaning the tank is a more complex operation that requires:

- Complete draining of the fuel

- Disassembly and internal cleaning

- Checking and possibly replacing the fuel pump

- Cleaning the supply lines

This operation is recommended at 100,000-150,000 km or when recurring fuel quality problems appear.

Replacing fuel filters

The fuel system includes several stages of filtration. The main fuel filter should be replaced according to the maintenance schedule—usually at every major service (15,000-20,000 km).

Signs of a clogged filter:

- Power loss during acceleration

- Uneven engine operation

- Difficult starting when cold

- Increased fuel consumption

Benefits of proper maintenance

A well-maintained fuel system offers:

- Optimal performance: The engine delivers its nominal power

- Lower consumption: Efficient combustion reduces consumption by up to 10%

- Lower emissions: Complete combustion reduces pollution

- Increased reliability: Lower risk of costly failures

- Higher residual value: The engine depreciates more slowly

Conclusion

Fuel system maintenance isn’t just about performance; it’s an investment in the engine’s longevity. By following simple practices — regular use of additives, choosing reliable fueling stations, and preventive maintenance — you can avoid costly repairs and keep the engine in optimal condition for many years.

Remember that prevention is always cheaper than repair, and a clean fuel system is the guarantee of a pleasant and economical driving experience.