- P0319 indicates crankshaft position sensor B circuit fault causing instability.

- Symptoms include misfires, service light, idle issues, power loss, and ABS/traction effects.

- Common causes: bad sensors, wiring, connectors, power circuit faults, magnets, EMI.

- Diagnosis focuses on visual inspection and power/CAN faults, not sensor replacements.

OBD2 error code P0319 is one of the more complex diagnostic issues in modern engine management, referring to a fault in the crankshaft position sensor B circuit. This error can significantly affect drive stability and may cause serious engine damage if not addressed promptly. The engine control module (PCM) detects unexpected variations in crankshaft position, which can lead to unstable and potentially dangerous engine operation.

What the P0319 code means

The PCM has detected a variation in crankshaft position that contributes to unstable and quite dangerous driving. The B sensor indicates a specific area of the rotary sensor circuit and is crucial for the correct engine timing.

When the P0319 code is set

When the PCM detects an unexpected variation in crankshaft position while you are driving, an error code will be stored and a service lamp will illuminate on the dashboard. This condition can appear suddenly or gradually, depending on the nature of the fault.

Symptoms of the P0319 fault code

Symptoms may include:

- Engine misfires accompanied by a stored code

- Service light on on the dashboard

- Idle instability or during acceleration

- Loss of power in certain driving conditions

- Traction control and/or ABS affected by conditions contributing to the stored code

- Abnormal engine vibrations

- Unusual noises from the engine area

Common causes of the P0319 code

Common causes include:

- Rotation sensors missing, unplugged, or faulty

- Damaged wiring for the crankshaft position sensor

- Corroded or poor-contact connectors

- Power circuit faults for the sensor

- Reference magnets of the crankshaft issues

- Electromagnetic interference in the engine management system

Common misdiagnoses

Technicians report that replacing wheel speed sensors, crankshaft position sensors, and camshaft sensors is a misguided maneuver when this code appears. Often the issue lies not with the sensor itself but with power circuits or the CAN communication system.

Diagnosing the P0319 code

Operation of rotation sensors

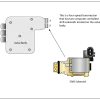

Modern OBD2 systems use rotation sensors to compensate small variations in the crankshaft and camshaft positions, caused by hard or uneven road surfaces during driving. These sensors are typically mounted near the wheels and can number from 1 to 4 sensors.

Sensors are usually variable-resistance devices and work with a stationary rheostat and a support arm. One end of the arm is attached to the sensor, and the other end is attached to the lower control arm or another component that reacts to road conditions.

Step-by-step diagnostic process

- Initial visual inspection

Start diagnostics with a visual inspection of all wiring and connectors. Repair or replace damaged, disconnected, shorted, or corroded wiring, connectors, and components as applicable.

- Code scanning

Connect a scan tool (or code reader) to the diagnostic port and record all stored codes. This information can be extremely helpful in diagnosing intermittent conditions that may have contributed to storing the code.

- Test after clearing codes

After codes are cleared, start the vehicle and drive to see if the code reappears. If the code does not return immediately, you may be dealing with an intermittent condition.

Testing rotation sensors

Checking connectivity

Inspect the connector faces to ensure they are clean, undamaged, and that components, wiring, and connectors are repaired or replaced as needed. A typical voltage reading at the sensor connectors is 5 volts, but check the manufacturer’s wiring diagrams and specifications.

Testing with a digital voltmeter

Using a digital voltmeter, test the sensor signal voltages and ground at the sensor connector. If both the signal and ground are present, reconnect the sensor and test the signal wire at the connector while simulating a fault condition on the road.

CAN (Controller Area Network) system

System complexity

CAN is a communication bus that allows multiple microcontrollers to communicate with each other without a host computer. The CAN bus network is effectively a complex bundle of wires and connectors used as a shared information conduit between two or more automotive control modules.

Interaction of modules

- The PCM receives a speed sensor signal from the vehicle

- This signal is systematically transmitted to affected control modules

- The cruise control module uses the data for speed control

- The traction control system uses the data to regulate traction control

- The ABS system compares the vehicle’s speed with the PCM

Repair recommendations

Diagnostic options

For vehicle owners:

- This type of code is best left to a professional due to the large number of circuits involved

- An experienced technician with a specialized scanner can determine the general fault area much faster

For experienced technicians:

- A specialized CAN diagnostic scanner will display PIN values and PCM operation

- It can diagnose computer and circuit problems accurately by monitoring vehicle operation

Diagnostic challenges

Diagnosing this code with a digital ohmmeter would involve testing thousands of circuits individually. At best, you could attempt a continuity test after disconnecting all control modules—this could take around 40 hours depending on the vehicle.

Advanced diagnostic steps

Testing grounding circuits

The grounding circuits of the control module must be tested to ensure continuity to the battery. An auxiliary ground strap can be useful in diagnosing this code.

Wiring check

Wiring in the vehicle is often left tangled after repairs. Look for disconnected or corroded electrical connectors, as they can raise circuit resistance and cause this code to appear.

Testing with an electrical schematic

Obtain a CAN bus system wiring diagram and a values diagram, then use a digital ohmmeter to test continuity between the individual controller connectors. Compare results with the manufacturer’s reference values and repair broken or shorted circuits.

Conclusion

The P0319 code represents a complex issue that requires advanced knowledge of a modern vehicle’s electronic systems. While the initial diagnosis can be performed by the vehicle owner, complete resolution typically requires the intervention of a specialist equipped with specialized diagnostic tools.