- P0324 indicates knock sensor circuit fault with abnormal cylinder readings.

- It can appear with P0325–P0327 related codes.

- The knock sensor is a piezoelectric device signaling the PCM to adjust timing.

- Voltage variation exceeding 10% from spec triggers the code.

Introduction

OBD2 code P0324 indicates a fault in the engine knock (detonation) sensor circuit. This issue can affect engine performance and requires a systematic approach for diagnosis and repair. The Powertrain Control Module (PCM) detects an abnormal knock sensor voltage reading for a cylinder that falls outside the manufacturer’s preset limits.

The knock sensor plays a crucial role in optimizing engine operation by continuously monitoring potential abnormal noises and transmitting this information to the control unit. When these values stray from normal, the P0324 code is triggered.

What P0324 Code Means

The PCM has detected a knock sensor circuit input reading for a cylinder that is not within the manufacturer’s preset limit. This code may appear alongside other related codes, such as P0325, P0326 or P0327, which refer to different aspects of the knock sensor system.

How the Detonation Sensor Works

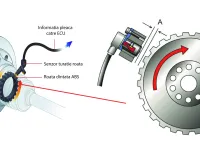

The detonation sensor is a piezoelectric component that detects abnormal engine vibrations caused by detonation (engine knocking). When it detects such vibrations, the sensor generates an electrical signal that is sent to the PCM. Based on this information, the PCM can adjust ignition timing to prevent engine damage.

Code Parameter Settings

Typical detonation sensor circuits consist of a single wire carrying a 5-volt signal. If the voltage readings vary by more than 10% from the manufacturer’s reference voltage, a code is stored in the PCM and a Fault/Check Engine lamp on the dashboard will illuminate.

Some models require multiple fault cycles before the MIL (Malfunction Indicator Lamp) lights. This feature is implemented to avoid false alarms and to ensure the issue is real and persistent.

Detection Conditions

- The engine must be at its normal operating temperature

- Engine RPM must be within a manufacturer-specified range

- Engine load must be sufficient to allow detonation detection

Symptoms of OBD2 Code P0324

These may include a loss of power, poor acceleration, and a service engine light on the vehicle’s dashboard. The MIL may stay on, illuminate and fade intermittently, or stay on for long periods and then go off for short or long periods.

Additional Symptoms

- Audible detonation: A distinct metal knocking sound (“pinging”), especially under load

- Increased fuel consumption: Due to suboptimal ignition timing

- Reduced performance: Poor acceleration and delayed throttle response

- Safety/limp mode operation: The PCM may limit power to protect the engine

Common Causes of OBD2 Code P0324

Because the detonation sensor is responsible for making the PCM aware of unexpected engine noises (primarily caused by an incorrect air/fuel mixture), this code is often the result of a more serious problem.

Primary Causes

- Faulty detonation sensor: Most likely culprit when other systems function normally

- Damaged wiring: Broken, shorted, or corroded wires

- Loose or corroded connectors: Weak connections between the sensor and PCM

- Mechanical engine problems: Bearing wear, issues with rings or valves

Locating the Sensor

If you have other codes, repair them before diagnosing this code. If the engine runs smoothly and the code persists, the most probable cause is a faulty knock sensor.

Some models locate the knock sensor near the starter, and the knock sensor connector is often damaged during starter replacement. This situation is common on high-mileage vehicles that have needed a starter replacement.

Common Diagnostic Mistakes

Replacing the knock sensor incorrectly when the problem lies elsewhere. Make sure the knock sensor is actually doing its job before replacing it.

Common Mistakes

- Premature sensor replacement: Without prior wiring checks

- Ignoring other codes: Overlooking related codes that could indicate the root cause

- Superficial testing: Checking only the sensor without evaluating the entire circuit

Diagnosing OBD2 Code P0324

Many manufacturers use one or more knock sensors fitted to the engine block. Typically, V-shaped engines will require at least 2 knock sensors, one for each bank of cylinders. Other manufacturers equip vehicles with a knock sensor for each cylinder.

Bank Identification

Bank 1 refers to the bank of the engine that contains cylinder 1, while Bank 2 refers to the bank that does not contain cylinder 1. This identification is crucial for correctly locating the defective sensor.

How It Works

The knock sensor is a single-wire device that uses a low-voltage signal to detect excessive engine noise. The PCM constantly monitors the knock sensor voltage and responds accordingly. Once the PCM receives an abnormal signal from the knock sensor, it can adjust the engine timing to reduce knocking or prevent further engine damage.

Diagnostic Procedure

A scanner (or code reader) and a digital voltmeter/ohmmeter are useful for diagnosing this code.

Step 1: Visual Inspection

Begin diagnosis with a visual inspection of all wiring and connectors. Repair or replace damaged, disconnected, shorted, or corroded wiring, connectors, and components as applicable.

Always retest the system after repairs to ensure success.

Step 2: Code Scanning

If all wiring, connectors, and components (including fuses) appear normal, connect the scanner to the OBD diagnostic port and record all stored codes.

This information can be extremely helpful in diagnosing intermittent conditions that could have contributed to the code storage.

Step 3: System Testing

After clearing codes, start and drive the vehicle to see if the code reappears. If the code does not return immediately, you may have an intermittent condition.

Intermittent conditions can prove challenging to diagnose and, in extreme cases, can worsen the situation before a proper diagnosis.

Detailed Diagnostic Steps

Preliminary Check

Ensure the engine has adequate oil by checking with a dipstick. Continue diagnosing while listening for excessive engine noises. If the PCM stores other codes, diagnose and repair them before attempting to diagnose this code. It may be a reaction to another engine issue.

Oil Pressure Testing

If abnormal engine noises are detected, perform a manual oil pressure test and compare your findings with the manufacturer’s recommendations. Replace worn or defective components as needed. Clear the codes and drive the car to verify that the repair was successful.

Sensor Testing

If the engine sounds normal and there are no other codes, disconnect the electrical connector from the affected sensor and test the sensor resistance. Compare your findings with the manufacturer’s specifications. Replace the sensor if necessary. Clear the codes and drive the vehicle to ensure the repair was successful.

Circuit Checking

If the sensor is functioning, disconnect the knock sensor connector and test the reference voltage. If there is no reference voltage, inspect the circuit and look for burnt, shorted, or damaged wiring of the knock sensor. Oil that has leaked onto the sensor wiring can cause major failures. If the system wiring appears to be in good condition, disconnect the connectors from the knock sensor and from all connected controllers.

Continuity Testing

Perform a continuity and resistance test on all affected circuits. Compare your findings with the manufacturer’s specifications. Clear the codes and test to ensure the repair was successful.

Special Precautions

Some knock sensors are located in engine areas that are very difficult to access; they will be hard to test without removing major engine components.

Vehicles equipped with such knock sensors must be diagnosed carefully, and the knock sensor should be the last possible cause of failure.

Important Warnings

When replacing the knock sensor, ensure that it is not located in an engine block cooling passage. Removing the knock sensor from a cooling passage can cause extremely severe burns to the hands.

Repair Recommendations

- Always use OEM or equivalent quality parts

- Follow the torque specifications provided by the manufacturer

- Check the oil condition before and after the repair

- Perform a full test drive after the repair