- P0106 signals abnormal MAP sensor voltage compared to engine conditions and barometric pressure

- Activation requires MAP error for at least four seconds and out-of-range readings

- Symptoms include weak acceleration, rough idle, possible stalling and check engine light

- Causes: faulty MAP or barometric sensors, contamination, damaged wiring or connectors

The OBD2 error code P0106 is one of the more complex technical issues that modern vehicle owners may encounter. This error refers to the Manifold Absolute Pressure (MAP) sensor, which plays a crucial role in optimal engine operation. When this sensor does not function within normal parameters, it can significantly affect the vehicle’s performance.

Understanding this error code and how to resolve it can save time and money at the shop. Below, we explore in detail all aspects related to P0106, from causes and symptoms to diagnostic and repair methods.

What the P0106 error code means

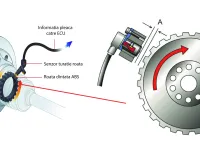

The P0106 code indicates that the engine control module (PCM/ECU) has detected an abnormally high or low voltage signal from the intake manifold pressure sensor. This signal may be incorrect for the engine’s current operating conditions (engine load and throttle angle) or may not correlate with the barometric pressure sensor.

The MAP sensor measures the absolute pressure in the intake manifold and transmits this information to the PCM as an electrical signal. When this signal falls outside preset parameters, the P0106 fault code is triggered.

Activation conditions of the P0106 code

For this code to be stored in the ECU memory, several specific conditions must be met:

- The air pressure sensor error persists for at least four seconds

- The sensor reading is outside the acceptable range compared to the reference voltage

- The difference between the measured pressure and the expected pressure exceeds the manufacturer’s threshold

- The engine operating conditions do not justify the sensor readings

Symptoms associated with the P0106 code

When this problem manifests, drivers may notice the following symptoms:

Performance issues

- Weak acceleration: The engine does not respond properly to the accelerator command

- Loss of power: General reduction in engine performance

- Rough idle: The engine may have idle stability problems

- Stalling: In severe cases, the engine may stall while driving

Visual and audible indicators

- Check Engine light: The warning lamp on the vehicle dashboard illuminates

- Unusual noises: The engine may produce unusual sounds

- Exhaust smoke: Possible appearance of blue or black smoke

Fuel consumption issues

- Increased fuel consumption: Notable rise in fuel usage

- Increased emissions: Emission levels exceed normal limits

Common causes of the P0106 fault

Identifying the exact cause requires a systematic analysis of several components:

Sensor-related issues

- Faulty MAP sensor: Internal sensor deterioration

- Barometric sensor degraded: Problems with the atmospheric pressure sensor

- Contamination on the sensor: Oil deposits, dirt, or other substances

Electrical problems

- Damaged wiring: Broken wires, shorts, or loose connections

- Corroded connectors: Oxidation or deterioration of electrical connectors

- Incorrect power supply: Issues with the sensor’s power circuit

Mechanical problems

- Vacuum leaks: Cracks in vacuum lines or intake manifold

- Clogged air filter: Restricted air flow to the engine

- Catalytic converter issues: Blocked exhaust system

- Throttle body problems: Malfunction of the throttle plate

PCM issues

- Defective control module: PCM failure (rare but possible)

- Corrupted software: Problems with PCM programming

Common diagnostic mistakes

Many mechanics make certain common errors when diagnosing this code:

Premature sensor replacement

Often, MAP or air flow sensors are replaced without a complete diagnosis, when the problem could be resolved by:

- Cleaning existing sensors

- Repairing electrical connections

- Checking the vacuum system

Ignoring basic mechanical issues

Before focusing on electronic components, it is essential to check:

- Overall engine condition

- Intake and exhaust systems

- Air and fuel filters

Detailed diagnostic procedure

Preparation for diagnosis

For accurate diagnostics, you’ll need:

- Professional OBD2 scanner

- Digital multimeter

- Manufacturer service manual

- Vacuum/pressure verifier

- Electrical contact cleaner

Diagnostic steps

1. Initial visual inspection

Always start with a thorough visual check:

- Inspect all wiring: Look for damage, cuts, or burn marks

- Check connectors: Ensure they are firmly connected and free of corrosion

- Inspect vacuum hoses: Look for cracks or loose connections

- Check the air filter: A clogged filter can affect sensor readings

2. Error code scanning

- Connect the OBD2 scanner to the diagnostic port

- Record all stored codes and freeze-frame data

- Note the conditions under which the error occurred

- Clear the codes and restart the engine to test for persistence

3. MAP sensor testing

- Check power supply: Measure reference voltage (usually 5V)

- Test the signal: Check sensor output at idle and under load

- Compare with specifications: Refer to the service manual for expected values

- Test with external vacuum: Apply different vacuum levels and monitor response

4. Electrical circuit verification

- Disconnect the MAP sensor connector

- Check continuity of wires between sensor and PCM

- Measure circuit resistance

- Look for short circuits or open circuits

5. Vacuum system analysis

- Inspect all vacuum lines

- Test the intake manifold for leaks

- Check throttle body operation

- Inspect the PCV system (Positive Crankcase Ventilation)

Specific tests for the MAP sensor

Static pressure test

With the engine off:

- Connect a vacuum pump to the MAP sensor

- Apply 20 inHg of vacuum

- The voltage should drop to about 1V

Dynamic test

With the engine running:

- At idle: voltage should be between 1-2V

- During sudden throttle input: voltage should rise to 4-5V

- The transition should be smooth, without jumps

Solutions and repairs

Simple repairs

Many P0106 issues can be resolved by:

- MAP sensor cleaning: Use electrical contact cleaner

- Repairing connections: Cleaning and tightening connectors

- Replacing the air filter: A clean filter improves air flow

Intermediate repairs

- Repair vacuum hoses: Replace damaged segments

- Clean the throttle body: Remove carbon deposits

- Repair wiring: Replace damaged wires

Complex repairs

- MAP sensor replacement: When the sensor is irreversibly damaged

- Repairing the intake manifold: In case of cracks or leaks

- PCM reprogramming: Very rare cases when the module is defective

Preventing future issues

To prevent recurrence of code P0106:

Regular maintenance

- Replace the air filter as per schedule

- Periodically clean the MAP sensor

- Check vacuum hoses annually

Monitoring vehicle health

- Periodically use an OBD2 scanner for preventive checks

- Be alert to changes in engine behavior

- Do not ignore minor symptoms that can worsen

Choosing quality parts

- Use OEM or equivalent quality parts

- Avoid questionable aftermarket sensors

- Ensure proper installation

Conclusion

The P0106 error code may seem complex at first glance, but with a systematic approach and the right tools, it can be diagnosed and repaired efficiently. The key is to avoid jumping to conclusions and to follow a logical diagnostic procedure.

If you lack the experience or tools, we recommend consulting a qualified automotive specialist. A correct initial diagnosis can save significant time and money, preventing unnecessary replacement of components that are functioning normally.