- P0014 signals camshaft timing out of sync with crankshaft due to VVT/VCT

- B-code indicates exhaust-side cam position; timing variations trigger fault around 10 degrees

- Symptoms include Check Engine light, poor economy, reduced performance, hard starts, limp mode

- Common causes: VVT solenoid, electrical issues, worn timing components, faulty sensors

P0014 is one of the more complex OBD-II fault codes that can appear on modern vehicles. This issue refers to camshaft position timing errors and the performance of the variable timing system on cylinder 1. Understanding this code is essential for accurate diagnostics and to avoid unnecessary repairs.

What the P0014 Code Indicates

This fault code directly involves VVT (Variable Valve Timing) or VCT (Variable Camshaft Timing) components and the Powertrain Control Module (PCM) or Engine Control Module (ECM). An important note is that the “B” in the full code indicates the camshaft is positioned on the exhaust side of the cylinder head, not on the intake side.

VVT and VCT systems are advanced technologies that allow the timing of valve opening and closing to be adjusted based on engine operating conditions. This flexibility improves performance, fuel economy, and emissions.

P0014 Code Setting Conditions

The P0014 code is stored in the PCM memory when timing variations between the camshaft and crankshaft exceed the manufacturer’s reference value. The typical limit is about 10 degrees at idle, but it can vary by make and model.

The control module constantly monitors the synchronization of these components via dedicated sensors. When it detects a difference beyond normal parameters, it automatically triggers this fault code.

Specific Symptoms of the P0014 Code

Symptoms can vary in intensity, but the most common include:

- Check Engine light illuminated on the dashboard

- Higher fuel consumption than normal

- Reduced engine performance, especially under acceleration

- Difficult starts or rough idle

- Excessive engine vibration

- In severe cases, the engine may enter an emergency/limp mode

Common Causes of the P0014 Code

Correctly identifying the cause is crucial for an effective repair. The main causes are:

Problems with the VVT/VCT Solenoid

- Faulty or sticking solenoid

- Insufficient electrical power to the solenoid

- Buildup of deposits in the solenoid

Electrical Circuit Failures

- Damaged or broken wires

- Corroded or oxidized connectors

- Short circuits in the electrical system

Mechanical Timing System Problems

- Worn timing belt/chain

- Faulty or stretched tensioner

- Worn timing gears

- Worn or damaged camshaft

Problems with the Sensors

- Faulty crankshaft position sensor

- Faulty camshaft position sensor

- Incorrect distance between sensor and target

Common Diagnostic Mistakes

A frequent mistake in diagnosing this code is quickly replacing sensors or even the PCM without thorough verification. These components are rarely defective, and replacing them without proper diagnosis can lead to unnecessary costs.

Other common errors include:

- Ignoring the timing system inspection

- Neglecting VVT solenoid cleaning

- Not monitoring engine oil quality

- Skipping electrical circuit testing

Detailed Diagnosis of the P0014 Code

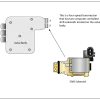

Principle of Sensor Operation

The crankshaft and camshaft positions are monitored by electronic Hall-effect or inductive sensors. They detect notches, grooves, or lobes on the engine shafts to determine the exact position.

Sensors generate variable voltage signals depending on interruptions in the magnetic field. These variations are interpreted by the PCM as degrees of rotation and are used to calculate ignition and injection timing.

Diagnostic Equipment Needed

For a correct diagnosis you will need:

- A professional OBD-II scanner or code reader

- A digital multimeter for electrical measurements

- An oscilloscope for waveform analysis

- The manufacturer’s service manual

- A timing system-specific tool kit

Step-by-step Diagnostic Procedure

Step 1: Visual Inspection Start by inspecting all wiring, connectors, and visible components. Look for signs of damage, corrosion, or loose connections. Also check the oil level and quality.

Step 2: Scan the Codes Connect the OBD-II scanner and record all stored codes. Information from other codes can provide clues about the underlying issue.

Step 3: Intermittent Testing

- Clear the code and restart the engine to see if it reappears quickly. If it does not return immediately, you may be dealing with an intermittent issue.

Step 4: Check Power Supply

- Test the reference signal (typically 5V) and ground at the sensor connector. If they are missing, trace the circuit back to the PCM.

Step 5: Waveform Analysis

- Use an oscilloscope to monitor sensor signals. Look for anomalies in the waveforms that could indicate sensor or mechanical target problems.

Step 6: Mechanical Verification

- If electrical tests are within spec, inspect the mechanical timing components, including correct tensioning and alignment of timing marks.

Special Considerations for Repairs

In some applications, repair may require replacing both the camshaft and crankshaft. This is a complex operation that requires full timing re-alignment and potentially PCM reprogramming.

Always consult the vehicle’s service manual for procedures specific to your vehicle, as methods can vary considerably between manufacturers and models.

Preventing P0014 Code Problems

To avoid the appearance of this code in the future, follow these recommendations:

- Perform regular oil changes with the appropriate quality oil

- Periodically check the timing belt/chain tension

- Avoid aggressive driving that can accelerate component wear

- Perform maintenance according to the manufacturer’s recommended schedule

Correct diagnosis of the P0014 code requires a methodical approach and proper equipment. While it may seem complex, a clear understanding of the systems involved and a structured diagnostic procedure can lead to rapid identification and resolution of the problem.