- P0299 signals turbocharger under-boost due to low pressure detected by PCM.

- Symptoms include reduced power, unusual noises, stored code, and MIL illumination.

- Common causes: clogged/faulty turbo, air restriction, bad pressure sensor, wastegate.

- Misdiagnosis: turbo replacement common; inspect turbine blockage and wastegate first.

OBD2 Error Code P0299 refers to the turbocharger error - its poor performance.

Indicator

This code indicates that a low-pressure condition has been detected by the PCM.

Code Setting Parameters

If the MAP sensor provides the PCM with data indicating that the pressure of the turbine or turbocharger has reached a level lower than the manufacturer’s preset amount, an error code will be stored and a malfunction indicator light will turn on the vehicle’s dashboard.

Symptoms of OBD2 P0299 Error Code

Symptoms can include reduced engine power, strange engine noises, a stored error code, and a service indicator light on the vehicle’s dashboard. Possible causes include a faulty turbocharger.

Common Causes of OBD2 P0299 Error Code

The most frequent causes include a clogged or faulty turbocharger, an air restriction or loss, a defective pressure sensor, or a faulty wastegate valve regulator. Various engines, actuating arms, diaphragms, and doors may also fail. Turbo pressure release valves are often replaced with adjustable high-performance aftermarket valves. This is done to achieve greater turbine pressure and increased power.

Common Misdiagnoses

The turbocharger is often mistakenly replaced due to the appearance of this code. Turbine blockage and wastegate valve malfunction are the main causes of this code.

Diagnosis of OBD2 P0299 Error Code

To successfully diagnose forced air induction turbines, we must understand how the forced air induction system works and how it is monitored. Forced air induction introduces excessive amounts of air into an engine to promote power gains. While a naturally aspirated engine uses the vacuum created by the downward piston movement to draw a controlled air/fuel mix into the engine’s combustion chambers, the forced air induction engine forces fuel and air into the combustion chambers using an alternatively driven device. Turbines are specifically designed for this task.

These forced air induction devices fall into three basic categories: turbochargers, radial compressors, and centrifugal compressors. Turbochargers use the engine’s exhaust pressure to propel rotors in a two-chamber housing. The two chambers are entirely separate from each other.

Exhaust pressure spins the rotor in chamber A, which in turn rotates a rotor in chamber B. The rotor in chamber B collects fresh air through the turbocharger’s intake system (and intercoolers) and forces the cooler, denser air into the engine.

Both types of compressors are belt-driven devices. The radial compressor sits on top of the engine and is bolted in place of the intake manifold. The centrifugal compressor is mounted at the front of the engine, much like an air conditioner compressor or an alternator.

Unlike the turbocharger, which uses engine exhaust for propulsion, the compressor has only one chamber.

Air is drawn into the device, compressed, and forced into the engine’s combustion chamber using a pair of independent rotors.

The centrifugal compressor uses a centrifugal mechanism to draw air into the housing, where it is compressed and reintroduced into the engine as cooler, denser air (in excessive amounts). Compressors also use intercoolers to cool the air before compressing and forcing it into the engine.

The denser air allows fuel to atomize more efficiently, thereby promoting greater engine power. Naturally, as the engine’s RPM level increases, turbochargers spin even faster.

The typical turbocharger doesn’t start working until the engine reaches 1,700 to 2,500 RPM, but it can operate at speeds of up to 250,000 RPM under maximum pressure (internal blade rotation speed). Extreme RPMs are required for the device to produce air pressure greater than atmospheric pressure.

These high air pressure levels are known as “boost pressure.” Each engine manufacturer provides minimum recommended pressure specifications programmed into the PCM.

When these specification limits aren’t met, a P0299 code is stored in the PCM, and a malfunction indicator light will illuminate on the vehicle’s dashboard.

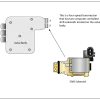

A scanner (or code reader) and a digital volt/ohmmeter will be useful for successfully diagnosing this code.

Begin the diagnosis with a visual inspection of all wires and connectors.

Repair or replace any damaged, disconnected, shorted, or corroded wiring, connectors, and components, as needed.

Always retest the system after completing repairs to ensure success. If all system wiring, connectors, and components (including fuses) appear in good order, connect the scanner (or code reader) to the diagnostic connector and record all stored codes.

This information can be extremely useful in diagnosing intermittent conditions that might have contributed to storing this code.

After clearing the codes, start and drive the vehicle to see if the code returns. If the code doesn’t return immediately, you might have an intermittent condition.

Intermittent conditions can be challenging to diagnose, and in extreme cases, the situation might worsen before a correct diagnosis is achieved.

Most malfunctions will be associated with a faulty pressure sensor or a faulty wastegate valve.

Suspect a faulty turbine when fuel consumption dramatically increases or when oil consumption is excessive.