- Poor-quality fuel causes 5-10 HP loss.

- Clogged air and fuel filters reduce air intake and power.

- Diesel engines suffer carbon buildup and EGR/DPF issues from city driving.

- DPF/EGR clogging can trigger safe mode; cleaning with high-pressure water is required.

It may have happened to you as well: one day your car’s engine no longer pulls as it used to, and acceleration feels much slower than usual. Power losses in engines are a common problem for both gasoline and diesel engines and can have many causes, from simple issues like clogged filters to wear of key components.

Over time, after many kilometers, engines begin to lose part of their initial power due to component wear and carbon deposits. Understanding the causes of these problems can save you time and money, helping you choose the right remediation.

Fuel quality – the primary cause of power loss

The most common cause of reduced power in an engine is poor fuel quality. Romania is among the countries with the lowest quality fuel in Europe, and recent studies show that this issue is not negligible.

A recent study showed that poor-quality fuel can cause you to lose around 5-10 HP. This finding was confirmed by dynamometer tests, proving that the impact is real, measurable, and not just theoretical.

Poor-quality fuel contains impurities that deposit in the injection system, on the valves, and in the combustion chamber, affecting the combustion process and reducing engine efficiency.

Filters and clogged lines – maintenance issues

After discussions with automotive service specialists, a worrying reality has emerged: many cars are not serviced correctly. There are vehicles that arrive with the air filter Never changed for 10 years!

Air filter and its impact on power

The air filter becomes clogged with time, leading to:

- Significantly poorer air circulation

- Difficulties in air intake

- Decreased engine power

- Higher fuel consumption

Fuel filter – an overlooked component

Equally important is the fuel filter. There are cars that travel with the original fuel filter, never replaced. Many owners adopt the mindset of “it will still run” and then wake up to a car that no longer pulls.

There have been cases where the fuel filter contained a black paste (similar to tar), and fuel could barely pass through the filter.

Problems specific to modern diesel engines

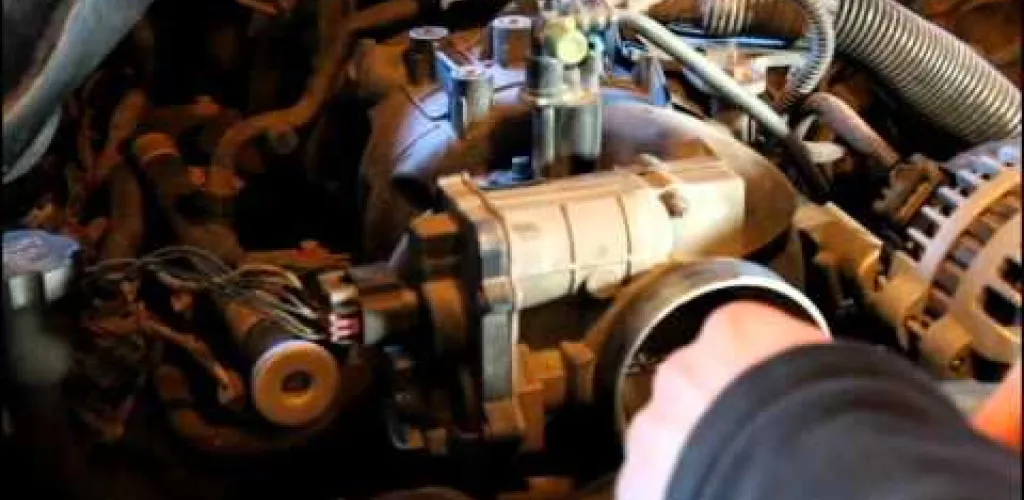

With the growth of diesel engines in Romania, especially the newer models equipped with DPF and EGR, more cases of clogged intake and EGR have appeared.

Carbon buildup – the enemy of diesel engines

Diesel cars that operate predominantly in city traffic, stop-and-go, at low revs, accumulate massive carbon buildup deposits. There have been cases where the intake was so clogged with carbon that air could only pass through a channel as wide as a finger.

Problems with the DPF and EGR

The DPF (diesel particulate filter) and the EGR (exhaust gas recirculation) are critical components that can clog:

- The DPF clogged by 90-95%

- The car refuses to pull

- It enters a safe mode

- It regenerates continuously

For these issues, the only effective solution is mechanical removal and cleaning with a specialized solution and high-pressure water.

Wear and tear in gasoline engines

Spark plugs – the spark of power

In gasoline engines, many drivers forget to replace the spark plugs, which over time wear out and no longer deliver optimal performance:

- The spark loses power

- Combustion becomes incomplete

- Power loss inevitably occurs

- Fuel consumption increases

Faulty sensors and their impact on the ECU

When sensors no longer read parameters correctly, the ECU cannot optimally control the engine, leading to:

- Considerable power loss

- Irregular operation

- Higher fuel consumption

- Higher pollutant emissions

Engine tuning and synchronization

If the engine is not properly tuned, it will not develop all of its power:

Non-synchronized timing

- The engine will not run properly

- It will not develop all available power

- Long-term engine problems may occur

Incorrect ignition timing

- The engine will be much lazier

- Fuel consumption will increase

- Power will drop significantly

Problems with the turbocharging system

Turbo wear

The turbocharger consists of two parts:

- The hot side (driven by exhaust gases)

- The cold side (which compresses the air)

To create boost in the intake, the turbine wheel inside the cold side has a very small clearance. If it wears even a little:

- It starts to lose pressure

- It fails to build the correct boost

- Power naturally drops

Variable geometry stuck

If the turbo’s variable geometry is stuck or does not slide properly, the turbine will not operate at optimum.

Injection system and its impact on power

A worn injection system can cause major problems:

Injector wear

- It no longer injects the correct amount of fuel

- The timing of injection is no longer optimal

- The engine no longer develops the same power

Nozzles clogged

- The nozzles wear or clog with carbon buildup

- They no longer spray fuel properly

- Incomplete combustion occurs

- Additional carbon deposits form

General engine wear

Engine wear is inevitable, especially in gasoline engines:

Piston ring wear

- Wears over time, especially with a sporty driving style

- Neglecting oil changes accelerates wear

- Compression and consequently power decrease

Valve stem seal wear

- Wears faster if the oil quality is poor

- Bluish smoke from the exhaust

- Oil consumption increases

- Oil enters the combustion chamber

Unusual cases and correct diagnosis

Sometimes the causes of power loss can be unexpected. A funny case involved a driver who presented with the problem “the car won’t pull.” After several mechanics looked at the engine and found nothing, the computer diagnostic technician discovered that the handbrake was engaged, but the indicator on the dashboard was not lit.

This driver had been driving for a long time with the handbrake engaged, thinking the car had engine problems!

Recommendations for diagnosis and repairs

Finding the cause of power loss is a complex process that requires:

Professional computer diagnostics

- Checking the engine operating parameters

- Ensuring there are no electrical problems

- Verifying proper sensor function

Avoiding repairs “by ear”

Dealing with the problem without professional diagnostics can lead to:

- Unnecessary replacement of many parts

- Worsening the situation

- Much higher costs in the long term

The importance of a specialized service

It is best to call on a specialized workshop for:

- Accurate diagnostics

- Correct repairs

- Avoiding future problems

- Saving time and money

Regular preventive maintenance and timely diagnostics can prevent major power losses and keep engine performance at an optimal level in the long term.