- Hydraulic pump creates high-pressure fluid to assist steering (up to 100–150 bar).

- Two types: mechanical belt-driven and electro-hydraulic with variable assist.

- Symptoms include stiff steering at low speeds and unusual noises.

- Rotary valve directs pressurized fluid to the steering cylinder for turning.

Power steering pumps are a key component of hydraulic steering that makes wheel handling effortless. Without this technology, steering a modern vehicle would require enormous physical effort, especially during parking or at low speeds. This vital part for road safety converts mechanical effort into smooth, controlled motion.

What is the power steering pump and how it works

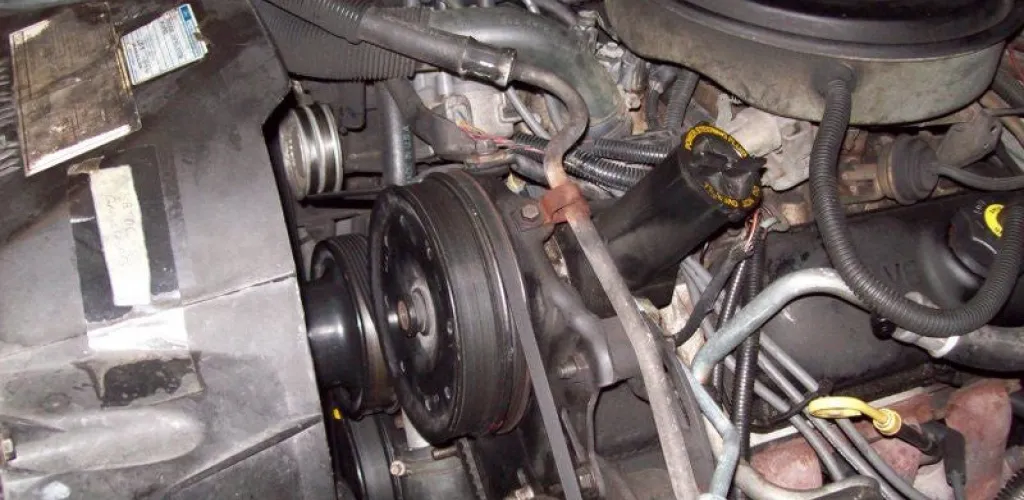

The power steering pump is a hydraulic pump mounted at the front of the engine, driven by the accessory belt. Its main role is to create high pressure in the hydraulic system and send the fluid under pressure to the steering gear.

Power steering works by transporting a special fluid from a dedicated reservoir, applying pressure to rotate the steering mechanism. This process allows the wheels to turn with minimal physical effort.

The system works on a simple principle: when you turn the wheel, a rotary valve in the steering gear directs the fluid under pressure to the corresponding hydraulic cylinder. The hydraulic pressure can reach up to 100-150 bar, providing a multiplier of force that turns a light steering motion into the precise turning of the wheels.

Types of power steering pumps

Mechanical hydraulic pumps

These are the most common type, driven mechanically by the engine via the accessory belt. They provide constant assistance and are very reliable, operating at speeds proportional to the engine RPM.

Advantages:

- Increased reliability

- Constant steering assist

- Simple maintenance

- Low repair costs

Disadvantages:

- Continuous power draw from the engine

- Assistance does not adapt to vehicle speed

Electro-hydraulic pumps

Used in modern vehicles, they run on electrical power and can be programmed to provide variable assistance based on vehicle speed. They are controlled by an electronic control unit that adjusts pressure in real time.

Advantages:

- Variable assist based on speed

- Lower fuel consumption

- Precise electronic control

Disadvantages:

- Higher complexity

- Higher repair costs

- Dependence on the electrical system

Symptoms of a faulty power steering pump

1. Loss of power steering

This is the most evident symptom – the steering wheel becomes very hard to operate. The problem is more noticeable at low speeds or when trying to turn on the spot. It takes longer for the car to turn or it may not turn at all, which can be extremely dangerous in traffic.

This symptom occurs gradually – initially you’ll feel increased resistance, then the steering will become completely stiff. In a complete failure, both hands and a lot of effort are needed to turn the wheel.

2. Unusual noises at the steering

A faulty pump will produce sounds that should not be ignored:

- Grinding noise: Occurs when the pump operates with insufficient or poor-quality power steering fluid

- Metal-on-metal squeal: Indicates the pump is near the end of its life and needs urgent replacement

- Squealing under the hood on a cold start: The pump may engage the timing belt or the accessory belt

- Creaking when turning: Signals issues with hydraulic pressure

These noises are more pronounced when the engine is cold or when turning the wheel to its full lock.

3. Stiff or unresponsive steering

The steering wheel may become completely rigid, making it impossible to operate. This is the last stage of failure, but if you ignore the other symptoms, you may find yourself in this dangerous situation.

In this case, driving becomes extremely dangerous, especially in corners or when avoiding obstacles.

4. Leaks of power steering fluid

Seeing green or red spots under the car may indicate leaks from hoses or the pump itself. The system operates at very high pressures, and hoses can crack over time.

Leaks can occur at:

- Damaged pump seals

- Cracked hydraulic hoses

- Loose fittings

- Fluid reservoir

5. Oscillations and vibrations in the steering wheel

Unusual vibrations may appear in the steering wheel, especially at high speeds or during turns. These can indicate:

- Internal wear of the pump

- Air in the hydraulic system

- Problems with pressure distribution

Diagnosing power steering pump problems

Road test

To test a power steering pump, pick an open road with plenty of turns, preferably at night when traffic is light. Observe the symptoms described above while driving.

Note: If the steering does not respond fully, avoid driving to prevent endangering yourself.

Visual inspection

- Pump inspection: Check for visible cracks or leaks

- Belt condition: Inspect wear and belt tension

- Hydraulic hoses: Look for signs of damage or leaks

- Fluid level: Check quantity and quality of the fluid

Mechanical tests

- Pressure test: Measure system pressure with a special manometer

- Flow test: Check the amount of fluid pumped per unit time

- Temperature test: A faulty pump overheats excessively

Repairing and maintaining the power steering pump

The major issue with power steering pumps is often the fluid. Before considering replacement, check the following aspects that can resolve the problem at a lower cost.

1. Inspecting and topping up the fluid

Locating the reservoir

The reservoir is located in the engine bay, usually near the radiator, on the right or left side. The cap is stamped with the power steering symbol or the words Power Steering.

Checking the level and quality

- Engine off: Let the engine cool for 5-10 minutes

- Open the cap: Turn the reservoir cap counterclockwise

- Pull out the dipstick: Remove the dipstick attached to the cap

- Clean the dipstick: Wipe with a clean cloth and check the marks

- Measurement: Reinsert the dipstick fully, then remove again

- Interpretation: The level should be between MIN and MAX

Refill with new fluid

If the level is low:

- Use only the fluid recommended by the manufacturer

- Add gradually, avoiding overfilling

- Check the color – old fluid turns brown or black

- Replace the fluid completely if contaminated

2. Bleeding the hydraulic system

Air in the hydraulic system can cause the pump to malfunction:

- Refill the reservoir with fresh fluid

- Start the engine and let it idle

- Turn the steering wheel from lock to lock several times

- Check the level and top up if needed

- Repeat until the noises disappear

3. Replacing the accessory belt

A worn or improperly tensioned belt can affect pump operation:

- Check that the belt is not slipping on the pulley

- Replace the belt if cracked or worn

- Adjust tension according to the manufacturer’s specifications

When replacement is necessary

The pump should be replaced in the following situations:

Irreversible internal damage

- Wear of internal vanes or pistons

- Damage to the pump body

- Seizure of internal mechanism

Major leaks

- Cracks in the pump housing (cast iron)

- Damage to the main seals

- Excessive shaft wear

Insufficient performance

- The pump no longer generates the required pressure

- Noises persist after all checks

- Excessive fluid consumption

The pump replacement process

Removing the old pump

- Drain the system: Remove fluid from the reservoir

- Disconnect the lines: Mark positions for reassembly

- Loosen the belt: Release tension and remove the belt

- Unbolt the pump: Remove mounting bolts

Installing the new pump

- Check compatibility: Ensure the new pump is identical

- Reverse assembly: Follow removal steps in reverse order

- Tightening correctly: Adhere to the specified torque values

- Refill with new fluid: Use only the recommended fluid

Power steering pump replacement cost

The cost of replacing a power steering pump varies significantly depending on several factors:

Factors influencing price

Vehicle type:

- Small class vehicles: 800-1,200 RON

- Mid-class vehicles: 1,200-1,800 RON

- Premium vehicles: 1,800-3,000 RON

- Commercial vehicles: 1,500-2,500 RON

Type of pump:

- Standard hydraulic pumps: lower cost

- Electro-hydraulic pumps: 30-50% higher cost

- Pumps with integrated sensors: the most expensive

Origin of the part:

- OEM parts: 40-60% more expensive

- High-quality aftermarket parts: optimal cost/benefit

- Reconditioned parts: 30-40% cheaper

Additional costs

- Power steering fluid: 50-100 RON

- Filters and seals: 80-150 RON

- New accessory belt: 60-120 RON

- System bleeding: 100-200 RON labor

Estimates for popular brands

| Brand | Model | Estimated cost (RON) |

|---|---|---|

| Dacia | Logan/Sandero | 900-1.300 |

| Volkswagen | Golf/Passat | 1.400-2.000 |

| BMW | Series 3/5 | 2.200-3.500 |

| Mercedes | C/E Class | 2.500-3.800 |

| Audi | A4/A6 | 2.000-3.200 |

Tips to extend the life of the power steering pump

Preventive maintenance

- Check monthly the level of power steering fluid

- Replace the fluid according to the maintenance schedule (at 60,000-80,000 km)

- Avoid holding the wheel at the extreme positions for long periods

- Repair leaks quickly to prevent pump damage

- Check the accessory belt and replace when worn

Good driving habits

- Do not force the steering wheel when the car is stopped

- Warm up the engine before intensive maneuvers

- Avoid sharp turns at high speeds

- Periodically check tire pressure to reduce steering effort

Early warning signs

- Any change in the effort required to turn the wheel

- New noises when turning

- Fluid level drop without an obvious reason

- Unusual vibrations in the steering wheel

Consequences of neglecting the power steering pump

Safety risks

- Loss of vehicle control in critical situations

- Road accident due to inability to avoid obstacles

- Extreme physical effort to maneuver the vehicle

Additional costs

- Damage to the steering gear from running with no fluid

- Premature wear of suspension system components

- Complete replacement of the hydraulic system

Conclusion

The power steering pump is a critical component for safe and comfortable driving. Early recognition of symptoms and preventive maintenance can prevent costly repairs and ensure safe driving. Investing in regular checks and timely fluid replacement can significantly extend the pump’s life.

At the first signs of failure – unusual noises, a stiff steering wheel, or fluid leaks – consult a specialized mechanic for a professional diagnosis. Delaying repairs can turn a minor issue into a major failure with higher costs and safety risks.

Sursa foto: youtube.com, instructables.com, automedicsafrica.com, yourmechanic.com, holley.com