- P0087 indicates fuel pressure is below the manufacturer’s specified range.

- Symptoms include power loss, stalling, and hard starts.

- Main mechanical causes: faulty pump, clogged filter, defective regulator, restricted lines.

- Electrical causes: faulty pressure sensor, bad relay, wiring, or loose connectors.

The P0087 OBD-II code indicates insufficient fuel delivery pressure, a critical issue that can severely affect engine performance. Diagnosing it requires a systematic approach and prompt intervention to avoid costly engine damage.

The fuel delivery system operates at precise pressures set by the vehicle manufacturer based on engine type and injection system. When pressure drops below these targets, the PCM detects the anomaly and stores the P0087 code, signaling the need for technical intervention.

What the P0087 error code means

PCM (Powertrain Control Module) has detected that fuel pressure in the fuel system is below normal operating parameters. This pressure is essential for optimal fuel injection and normal engine operation.

The monitoring system continuously compares the actual pressure with the programmed pressure in the PCM software. When the difference exceeds acceptable tolerances, the error management procedure is activated and the P0087 code is stored.

When the P0087 code triggers

- Fuel pressure is outside the manufacturer’s preset limits

- PCM detects a significant difference between the desired and the actual pressure

- The problem persists for a defined period (usually 2-3 driving cycles)

- The Check Engine light comes on

- The fuel pressure sensor transmits values outside normal parameters

Many modern vehicles have protective systems that limit engine power when fuel pressure is insufficient to prevent internal engine damage.

Specific symptoms of the P0087 code

Main symptoms

- Loss of engine power during acceleration, manifested as a delayed response to pedal input or an inability to reach requested RPM

- Engine stalling may occur at idle or in motion, and can be dangerous in traffic

- Hard starting or failure to start manifested by extended cranking or intermittent starts

- Check Engine light is the first visible indicator, possibly intermittent in early stages

Secondary symptoms

- Increased fuel consumption due to PCM compensation

- Higher pollutant emissions detectable at periodic tests

- Abnormal engine vibrations, especially at idle

- Unusual noises from the fuel pump area

- Rough running at idle

- Hesitation of the engine during acceleration

Main causes of the P0087 code

Mechanical causes

- Faulty fuel pump can struggle to maintain pressure due to internal motor issues, a failing turbine, or seal problems

- Clogged fuel filter restricts fuel flow and pressure

- Defective pressure regulator can no longer maintain constant pressure, causing fluctuations

- Worn or obstructed fuel lines may leak or restrict flow, lowering pressure

Electrical causes

- Faulty fuel pressure sensor may send erroneous signals to the PCM despite normal pressure

- Damaged fuel pump relay can cause intermittent or insufficient power to the pump

- Corroded or broken wiring in the pump circuit or sensor circuit can cause erratic operation

- Oxidized or loose connectors can introduce parasitic resistance affecting power delivery

Systemic causes

- Defective PCM may misinterpret sensor signals or have control algorithm issues

- Injectors with internal leaks can reduce pressure in the supply line

- Faults in the pump control module in vehicles with sophisticated fuel management systems

Common incorrect diagnostic mistakes - beware of traps

Critical note: Many expensive components (fuel pumps, pressure sensors, regulators) have been replaced unnecessarily when the vehicle was simply out of fuel. The fuel gauge on the dash can be faulty or inaccurate, so always verify the actual fuel level in the tank before any diagnosis.

Other common mistakes include:

- Replacing the pump without checking the fuel filter

- Changing the sensor without testing wiring

- Ignoring checks of relays and fuses

- Not following proper depressurization procedures

Complete diagnostic process

Step 1: Initial visual check

Visually inspect all wires and connectors near the fuel tank and engine bay for signs of scorch marks, corrosion, or physical damage.

Check all fuses related to the fuel system, including main fuses and auxiliary ones.

Confirm the actual fuel level in the tank using a clean dipstick or by controlled filling to a known volume.

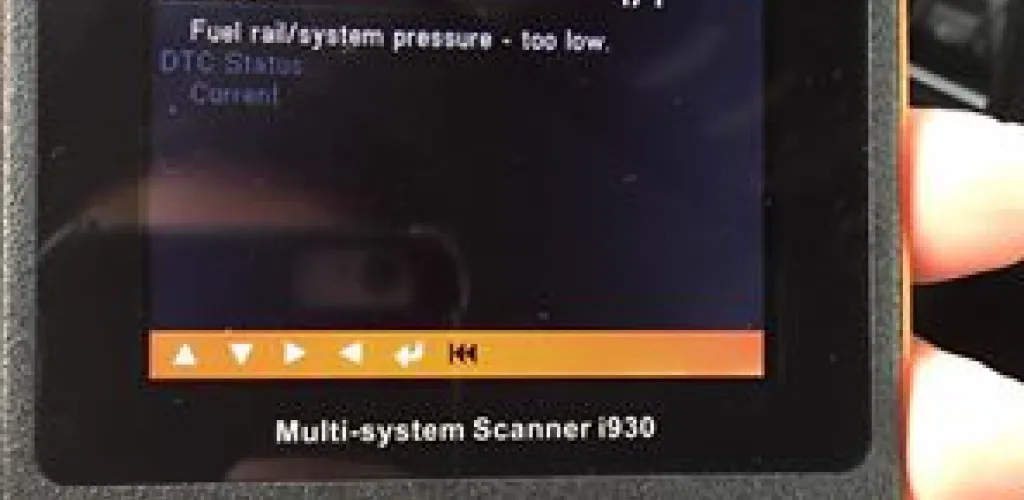

Step 2: Scan and record codes

Connect an OBD2 scanner to the diagnostic port and record all stored error codes, both active and historical.

Note the freeze-frame data to analyze the context in which the error appeared—engine temperature, RPM, load, and vehicle speed.

Clear the codes and perform a test drive to see if they reappear immediately or under certain operating conditions.

Step 3: Fuel pressure testing

Equipment needed: Fuel pressure gauge with adapters appropriate for the vehicle under test.

Connect the gauge to the test port (if present) or to the fuel line, following safety procedures for working with gasoline.

Measure pressure with the engine off and ignition on (the pump should run for 2-3 seconds), then with the engine idling and during acceleration.

Typical pressure values:

- Indirect injection engines (port fuel injection): 2.5-4.0 bar

- Direct gasoline injection engines: 50-200+ bar

- Diesel engines with common rail: 1000-2000+ bar

- Diesel engines with mechanical pump: 2-4 bar

Test the pressure hold after turning off the engine — it should drop slowly, not abruptly, indicating the system is sealed.

Step 4: Fuel pump testing

Audible method: Listen carefully for the pump sound when the ignition is turned on. The pump should run for 2-3 seconds with a uniform hum, without abnormal noises or intermittent operation.

Mechanical stimulation method (in-tank pumps): Lightly strike the fuel tank with a rubber mallet while another person starts the engine. If the engine starts briefly, the pump may have intermittent mechanical issues.

Electrical method: Measure the pump current draw with a clamp meter — abnormal draw (too high or too low) can indicate internal pump problems.

Step 5: Electrical circuit check

Test the voltage at the fuel pump connector — there should be source voltage (typically 12V) when the ignition is on or the engine is running.

Check the pump relay by temporarily swapping with a similar relay from another function (air conditioning, cooling fan), or test with a multimeter.

Check continuity of wiring from the relay to the pump and from the pump to the PCM, looking for abnormal resistances or breaks.

Verify the electrical grounding of the pump — a faulty ground can cause intermittent operation.

Step 6: Diagnosing the fuel pressure sensor

Location: The fuel pressure sensor is usually on the fuel rail or the main supply line.

Disconnect the sensor connector and verify:

- Reference voltage (usually 5V on one wire)

- Ground signal on another wire

- Continuity of the signal wire to the PCM

Test the sensor resistance with a multimeter and compare to the manufacturer’s data.

Measure the sensor’s analog output under varying pressure to verify linear response.

Detailed repair options

Replacing the fuel pump

Estimated cost: €150-€400 for parts + €100-€200 for labor

Procedure:

- Completely depressurize the fuel system

- Disconnect the battery and observe safety delays for airbags

- Gain access to the pump by removing seats or the fuel tank access panel

- Disconnect electrical connectors and fuel lines

- Remove the pump retaining ring with special tools

- Carefully extract the pump to avoid damaging the level sensor

- Install the new pump with fresh seals

- Reassemble and test the system for leaks

Replacing the fuel filter

Estimated cost: €20-€80 for parts + €30-€50 for labor

The filter should be replaced according to maintenance schedule or when fuel pressure is insufficient due to clogging.

Wiring repair

Estimated cost: €30-€100 parts + €80-€150 labor

Use appropriately sized wires and corrosion protection. All joins must be sealed and protected.

Replacing the pressure sensor

Estimated cost: €80-€250 for parts + €50-€100 labor

Use only genuine or equivalent quality parts to avoid PCM compatibility issues.

Critical safety procedures

- Avoid fuel vapors; gasoline vapors are highly flammable and can ignite from sparks, cigarettes or hot surfaces

- Depressurize the system before disconnecting any fuel lines

- Wear safety glasses and fuel-resistant gloves

- Ensure proper ventilation to avoid vapor buildup

- Have an ABC-type fire extinguisher nearby

Preventive measures to avoid problems

Regular maintenance

Replace the fuel filter per the manufacturer’s maintenance schedule — typically 30,000-60,000 km for gasoline vehicles and 15,000-30,000 km for diesel.

Use only high-quality fuel from reputable stations, avoiding stations with questionable stock rotation.

Avoid driving with a nearly empty tank — this can overheat the pump and draw in sediment.

Periodically clean the fuel system with specialist additives to prevent deposits.

Early warning signs

Unusual pump noises — louder sounds, vibrations or intermittent operation.

Difficulty starting when warm, indicating issues with internal seal integrity.

Intermittent power loss, especially during sustained acceleration.

Increased fuel consumption may indicate early fuel system problems.

Total repair costs

| Component | Part Cost (€) | Labor Cost (€) | Total (€) | Repair Time |

|---|---|---|---|---|

| Fuel filter | 20-80 | 30-50 | 50-130 | 1-2 hours |

| Fuel pump | 150-400 | 100-200 | 250-600 | 3-5 hours |

| Pressure sensor | 80-250 | 50-100 | 130-350 | 1-2 hours |

| Fuel pump relay | 15-50 | 20-40 | 35-90 | 0.5 hours |

| Wiring repair | 30-100 | 80-150 | 110-250 | 2-4 hours |

| Pressure regulator | 60-150 | 60-120 | 120-270 | 1-3 hours |

Note: Costs can vary significantly depending on vehicle make, part availability, and service rates.

Conclusion and final recommendations

P0087 is a serious issue that requires immediate attention to avoid engine damage from running with a lean air-fuel mixture. A methodical diagnostic approach, starting with simple checks and progressing to more advanced tests, will identify the exact cause and allow an efficient and cost-effective repair.

Do not overlook this error code, as it can lead to severe engine problems if left unresolved. The PCM power-limiting safety valve is only a temporary protection—the underlying issue must be fixed to avoid costly damage.

Investing in professional diagnostics can save hundreds of euros by avoiding unnecessary replacement of expensive components. Always follow safety procedures when working with fuel systems and do not hesitate to seek a specialist if you lack the necessary experience.