- MAP sensor measures intake manifold pressure to help PCM calculate air-fuel mix.

- Faulty MAP can raise fuel consumption by 10–30% and increase emissions.

- It can cause power loss and hard acceleration from wrong load readings.

- Emissions test failures due to incorrect exhaust gas composition.

The MAP sensor is a critical component in the electronic system of the modern engine. Present in all vehicles with electronic fuel injection, this sensor monitors the pressure in the intake manifold and transmits vital information to the engine control unit to optimize the air-fuel mixture.

A MAP sensor fault can cause a wide range of problems—from increased fuel consumption and power loss to starting difficulties and higher emissions. Early recognition of symptoms and correct diagnosis can prevent costly failures and keep your vehicle performing at its best.

What the MAP sensor is and how it works

The MAP sensor provides instantaneous information about the intake manifold pressure to the Powertrain Control Module (PCM). These data are used to calculate air density and determine mass flow, crucial for establishing the exact amount of fuel required for optimal combustion.

Principle of operation

Atmospheric pressure at sea level is approximately 14.7 PSI (1 bar). When the engine is not running, the pressure inside the intake manifold equals atmospheric pressure, and the sensor indicates this reference value.

During engine operation, piston movement creates a vacuum in the intake manifold. In a normally operating engine, the vacuum is around 18–20 inches of mercury (inHg), and the MAP sensor will indicate roughly 5 PSI. These pressure variations allow the PCM to calculate engine load precisely and adjust fuel injection accordingly.

Integration with engine systems

The MAP sensor works closely with other important components:

- IAT sensor (Intake Air Temperature) for converting pressure into information about air mass

- OBD-II system for testing the functionality of the EGR valve and other checks

- PCM (Powertrain Control Module) for real-time calculation of the optimal air-fuel mixture

- Oxygen sensor for validating combustion and fine adjustments

Main symptoms of a defective MAP sensor

Early recognition of fault signs can prevent more serious problems and costly repairs.

Increased fuel consumption

A MAP sensor reporting a higher pressure than actual indicates a high engine load to the PCM. Consequently, the system will inject an excessive amount of fuel, resulting in:

- Fuel consumption increasing by 10–30%

- Increased emissions of hydrocarbons and carbon monoxide

- Carbon deposits in the combustion chamber

- Premature wear of spark plugs

Loss of engine power

When the sensor reports a lower pressure incorrectly, the PCM interprets a reduced load and reduces the amount of fuel injected. Effects include:

- Engine that feels like it lacks power on acceleration

- Increased temperatures in the combustion chamber

- Higher emissions of nitrogen oxides (NOx)

- Difficulty climbing hills or overtaking

Emissions test issues

A defective MAP sensor directly affects exhaust gas composition:

- Higher hydrocarbon (HC) levels

- Excess NOx

- Reduced carbon dioxide (CO2)

- Increased carbon monoxide (CO)

- Emissions test failure (ITP)

Idle instability and irregular operation

Incorrect fuel injection causes:

- Idle speed oscillations

- Intermittent cylinder misfires

- Engine stalls when the AC is turned on

- Abnormal engine vibrations

Starting difficulties

An incorrect air-fuel mixture causes:

- Prolonged starting with multiple crank attempts

- Need to press the accelerator pedal

- Complete starting failure in severe cases

- Unstable operation immediately after starting

Unexpected engine shutdown

In advanced failure cases:

- Engine stops during driving

- Acceleration becomes unpredictable

- Overtaking safety is compromised

- Risk of stalling

Noises and detonations

An incorrect mixture can cause:

- Premature ignition of the mixture

- Detonations that produce engine knocking

- Accelerated wear of internal components

- Attention: Severe detonation can damage the engine!

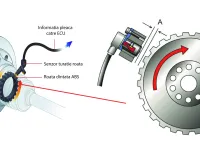

MAP sensor location

Sensor location varies by manufacturer and engine design:

Common positions:

- On the intake manifold - directly mounted

- On the throttle body - integrated or adjacent

- Remote location - connected via vacuum hose

- In the engine area - under the headlight assembly

- On the intercooler - in turbocharged engines

Correct identification: Refer to the vehicle’s technical manual for the exact location, as confusion with other sensors (MAF, IAT) is common.

MAP sensor cleaning procedure

Before replacement, a professional cleaning can restore proper operation.

Tools needed

- Vehicle technical manual

- Screwdriver set

- Electrical contact cleaner spray

- Lint-free rags

- Socket wrench (if required)

- Protective gloves

Cleaning steps

Vehicle preparation

- Turn off the engine and remove the key from the ignition

- Allow the engine to cool completely

- Disconnect the battery for safety

- Identify the sensor according to the manual

Removing the sensor

- Take photos of the position and connections for reassembly

- Carefully disconnect the electrical connector

- Remove the mounting screws

- Disconnect the vacuum hose (if present)

Cleaning itself

- Spray cleaner onto a clean cloth

- Gently rub all surfaces, avoiding excessive force

- Pay special attention to the sensor element

- Remove all carbon and oil deposits

Inspections and reassembly

- Visually inspect for cracks or damage

- Allow to dry completely before reassembly

- Reinstall in reverse order

- Check the seals of all connections

Advanced diagnostics and checks

Electrical testing

Power supply verification:

- Reference voltage: 5V ±0.25V

- Ground continuity: resistance under 1 ohm

- Signal wire integrity

Functional testing:

- Idle output signal: 1–2V

- Signal variation on acceleration

- Absence of electromagnetic interference

Associated components

Vacuum hose:

- Check for cracks, kinks, or clogs

- Test for leaks with a vacuum pump

- Replace if damaged

Intake system:

- Inspect the manifold for leaks

- Check the air filter and replace if needed

- Test EGR valve operation and PCV

OBD-II error codes

MAP sensor-specific codes:

- P0105: MAP sensor circuit - malfunction

- P0106: MAP sensor circuit - performance problem

- P0107: MAP sensor circuit - signal too low

- P0108: MAP sensor circuit - signal too high

- P0109: MAP sensor circuit - intermittent

Code interpretation:

- These codes can indicate sensor faults as well as issues with the electrical circuit or the vacuum system.

Replacement costs and considerations

Cost estimation

Replacement part:

- Aftermarket sensor: 80–150 lei

- OEM sensor: 200–400 lei

- Premium sensor: 300–600 lei

Labor cost:

- Independent workshop: 50–100 lei

- Authorized service: 100–200 lei

- Time: 30–60 minutes

Total estimate: 150–800 lei, depending on options

Factors influencing cost

- Sensor accessibility - some are hard to reach

- Removal complexity - may require removing other components

- Calibration required - some vehicles need special procedures

- Part quality - OEM vs aftermarket sensors

Preventing MAP sensor failures

Preventive maintenance plan

Every 15,000 km:

- Visual inspection of the sensor and connections

- Check vacuum hoses

- Scan for error codes

Every 30,000 km:

- MAP sensor cleaning

- Air filter replacement

- Inspect the intake system

Every 60,000 km:

- Clean the intake system

- Check the EGR valve

- Complete sensor testing

Factors accelerating wear

Operating conditions:

- Frequent urban traffic

- Use of lower-quality fuels

- Neglecting air filter replacement

- Aggressive driving with sudden accelerations

Related issues:

- Leaks in the intake system

- Stuck EGR valve

- Excessive carbon deposits

- Crankcase ventilation system problems

Early warning signals

Recognizing these signs can prevent major failures:

- Minor variations in fuel economy — increases of 5–10%

- Slight performance dips on acceleration

- Slightly unstable idle under load

- Intermittent messages on the dashboard display

- Engine sound changes at different RPMs

Actions recommended at the first signs

- Immediate scan with a diagnostic tool

- Preventive cleaning of the sensor

- Check the intake system

- Monitor parameters while driving

- Schedule a professional inspection

Environmental and safety impact

Environmental consequences

A MAP sensor fault contributes to:

- Increased pollutant emissions by up to 50%

- Excess fuel consumption and thus more CO₂

- Pollution standards violations on periodic tests

- Negative impact on air quality in urban areas

Safety considerations

On-road risks:

- Sudden power loss when overtaking

- Unexpected engine shutdowns

- Unpredictable acceleration

- Difficulties starting in emergency situations

Safety recommendations:

- Do not ignore symptoms, even if they seem minor

- Have repairs performed as soon as possible

- Avoid long trips with a faulty sensor

- Inform the mechanic of all observed symptoms

A MAP sensor in perfect working condition is essential for optimal performance, reduced fuel consumption, and controlled emissions. Investing in timely diagnosis and repair pays off quickly through fuel savings and avoidance of major engine failures.