- P0327 signals low voltage in Bank 1 Sensor 1 knock sensor circuit.

- Knock sensor helps the PCM adjust timing to prevent detonation damage.

- Symptoms include power loss, sluggish acceleration, and check engine light.

- Causes include faulty sensor, damaged wiring/connectors, or lubrication/fuel issues.

P0327 is an OBD2 trouble code that points to a fault in the knock sensor circuit on Bank 1, Sensor 1, characterized by low voltage. The Powertrain Control Module (PCM) has detected abnormally low voltage in the knock sensor circuit, which can affect engine performance and may lead to serious damage if not addressed promptly.

The knock sensor plays a crucial role in ensuring optimal engine operation, monitoring abnormal noises and helping the PCM adjust engine parameters to prevent damage from uncontrolled detonation.

What the P0327 code means

Knock sensor function

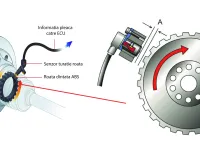

The PCM has detected a reading of the knock sensor circuit input voltage for a given cylinder that is outside the manufacturer’s preset limit. The knock sensor uses piezoelectric technology to detect the specific vibrations of engine detonation and transmits these signals to the PCM as voltage signals.

Code parameter settings

Typical knock sensor circuits consist of a wire with a 5-volt signal. If voltage readings vary by more than 10% from the manufacturer’s reference voltage, a code will be stored in the PCM and a fault indicator will illuminate on the vehicle’s dashboard. Some models require multiple fault cycles before the MIL lights up.

Symptoms of the P0327 fault code

Main signs indicating the presence of this fault code include:

- Engine power loss — reduced acceleration performance

- Poor acceleration performance — engine response becomes sluggish

- Check Engine light illuminated — the Check Engine indicator lights up

- Intermittent MIL behavior — it may stay on, flash, or stay on for long periods

In severe cases, the engine may run with improper timing, which can lead to overheating or internal engine damage.

Common causes of the P0327 code

Direct knock sensor problems

Since the knock sensor is responsible for making the PCM aware of unexpected engine noises (primarily caused by an incorrect air/fuel mixture), this code is often the result of a more serious underlying issue.

Contributing factors to the issue:

- Knock sensor faulty — most common case

- Damaged wiring — wires broken, corroded, or shorted

- Damaged connectors — especially on high-mileage vehicles

- Engine problems — actual detonation caused by poor fuel quality

- Lubrication issues — low oil level or poor-quality oil

- Unfavorable location — some models place the knock sensor near the starter, and the knock sensor connector is often damaged during starter replacement

Common misdiagnoses

Common diagnostic errors:

- Replacing the knock sensor in error when the problem lies elsewhere. Ensure the knock sensor is actually faulty before replacement. Many mechanics swap the sensor without thorough diagnostics, leading to unnecessary extra costs.

Step-by-step diagnostic process

Required equipment

An OBD2 scan tool (or code reader) and a digital multimeter will be useful for diagnosing this code.

System configuration

Many manufacturers use one knock sensor or multiple sensors feeding the engine control system. In V-type engines, at least two knock sensors are typically required, one for each bank. Other manufacturers equip vehicles with a knock sensor for each cylinder.

Bank identification:

- Bank 1 refers to the engine bank that contains cylinder 1

- Bank 2 refers to the engine bank that does not contain cylinder 1

Diagnostic steps

1. Initial visual inspection

Start the diagnosis with a visual inspection of all wiring and connectors. Repair or replace damaged, disconnected, shorted, or corroded wiring, connectors, and components as needed.

2. Checking error codes

Connect the scanner to the OBD connector and record all stored codes. This information can be extremely useful in diagnosing intermittent conditions that may have contributed to storing this code.

3. Testing engine operation

After clearing codes, start and drive the vehicle to see if the code reappears. If the code does not reappear immediately, you may have an intermittent condition.

4. Preliminary checks

- Ensure the engine has sufficient oil; check the oil level with a dipstick

- Listen for excessive engine noise

- If other codes are stored in the PCM, diagnose and repair them before diagnosing this code

Testing the knock sensor

1. Resistance testing

If the engine sounds normal and there are no other codes, disconnect the electrical connector from the affected sensor and test the sensor resistance. Compare the results with the manufacturer’s specifications.

2. Reference voltage testing

If the sensor operates within specifications, disconnect the sensor connector and test the reference voltage. If there is no reference voltage, inspect the circuit and look for burnt, shorted, or damaged knock sensor wiring.

Note: Engine oil that has spilled onto the sensor wiring can cause major failures.

3. Continuity testing

If the wiring harness appears to be in good condition, disconnect the connectors from the knock sensor and from all related controllers. Perform a continuity and resistance test on all affected circuits.

Important precautions

Sensor accessibility

Some knock sensors are located in very hard-to-reach areas of the engine, making them difficult to test without removing major engine components. Vehicles equipped with such knock sensors should be diagnosed carefully, and the knock sensor should be considered the last possible failure cause.

Safety during replacement

When replacing the knock sensor, ensure that it is not located in a coolant passage of the engine block. Removing the knock sensor from a coolant passage can cause severe burns.

Preventing future issues

To avoid recurrence of the P0327 code, follow these recommendations:

- Change the oil at the recommended intervals

- Use quality fuel

- Periodically inspect wiring in the engine bay

- Avoid exposing electrical connectors to excessive moisture

- Follow replacement procedures for components in the sensor area

Diagnosing the P0327 code correctly requires a systematic and patient approach, especially for intermittent conditions that can prove challenging to diagnose and, in extreme cases, may worsen the situation before a proper diagnosis.