- P0150 signals a fault in Bank 2 Sensor 1 oxygen sensor circuit.

- MIL illumination and degraded fuel economy often accompany the fault.

- Heater resistance is 8 ohms; 10% tolerance; 12.6–13.8V supply.

- Symptoms include rough idle, misfires, reduced fuel economy, and power loss.

The OBD2 code P0150 refers to a fault in the oxygen sensor circuit for Bank 2 Sensor 1. This issue can significantly affect engine performance and fuel economy, making timely diagnosis and repair essential.

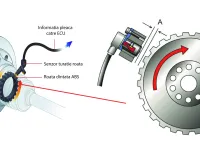

The oxygen sensor is a key component of the engine management system, responsible for monitoring the oxygen content in exhaust gases. This data allows the PCM (Powertrain Control Module) to optimize the air–fuel mixture for efficient combustion.

What P0150 Means

This code indicates that an oxygen sensor for Bank 2 Sensor 1 has transmitted a voltage signal outside normal parameters. Following this anomaly, the PCM stores the fault code and may illuminate the malfunction indicator lamp on the vehicle’s dashboard.

The notation “B2” represents Bank 2 of the engine, while “S1” indicates that the fault is in the upstream sensor, which is located before the catalytic converter.

Technical Parameters for Code Setting

- The oxygen sensor circuit operates with a standard heater resistance of 8 ohms. Variations greater than 10% in either direction will cause the P0150 code to be stored and the MIL to illuminate.

- For the heater circuit, the voltage must match the battery voltage (approximately 12.6–13.8 volts), with a tolerance of a maximum of 10%. Exceeding these limits will trigger the code in the PCM.

- During closed-loop operation, oxygen sensor readings that remain constant for an extended period (usually more than 8 seconds) can also cause this fault code to be stored.

P0150 Symptoms

The main symptoms indicating the presence of this fault include:

- Engine misfiring or rough running

- Reduced fuel economy

- Visible black smoke from the exhaust

- Check engine light illuminated on the dashboard

- Rough or unstable idle

- Power loss on acceleration

- Increased emissions

Common Causes

Sensor faults

- Worn or degraded oxygen sensor

- Sensor contaminated with residues or deposits

- Internal heater fault

Electrical issues

- Faulty electrical connector at the oxygen sensor

- Damaged or broken wiring

- Short circuit in the oxygen sensor circuit

- Corrosion of electrical contacts

Fuel system issues

- Low or excessive fuel pressure

- Faulty fuel injectors

- Clogged fuel filter

Other causes

- Faulty PCM (less common)

- Exhaust system problems

- Air leaks in the intake system

Common Diagnostic Mistakes

- Prematurely replacing the oxygen sensor without verifying electrical circuits

- Neglecting fuel pressure verification

- Replacing the wrong sensor (confusing upstream and downstream sensors)

- Overlooking wiring issues that can mimic a sensor fault

Step-by-step Diagnostic Process

Preparation for diagnosis

For effective diagnosis you will need:

- OBD-II scanner or code reader

- Digital multimeter

- Manufacturer service manual

- Tools to remove the sensor

Initial visual inspection

- Inspect the wiring: Visually check all harnesses and connectors for damage, disconnections, short circuits, or corrosion

- Check fuses: Ensure all system fuses are functional

- Repair visible faults: Repair or replace damaged components before continuing

Reading and clearing codes

- Connect the scanner to the diagnostic port

- Record all stored codes for future reference

- Clear the codes and restart the engine

- Check if P0150 reappears immediately

Testing the oxygen sensor

For modern engines equipped with OBD-II, most oxygen sensors are electrically heated. This system allows the sensor to reach operating temperature faster, reducing emissions and the time required for the PCM to enter closed-loop mode.

Verifying sensor operation

- Steady fluctuations between 100–200 millivolts

- Rapid response to changes in the air–fuel mixture

- Stable operation after reaching normal operating temperature

Testing the heater resistance

- Disconnect the sensor’s electrical connector

- Measure the resistance between the heater terminals

- Compare the result to the manufacturer’s specifications (usually 8 ohms ±10%)

Testing the electrical circuits

If the sensor appears functional, check:

- Continuity of wiring: Test continuity between the connector and the PCM

- Power supply voltage: Check the presence of battery voltage at the heater

- Ground: Ensure the PCM’s ground is stable

Checking fuel pressure

Incorrect fuel pressure can affect sensor operation:

- Low pressure: lean mixture, incorrect readings

- High pressure: rich mixture, sensor contamination

Repair Procedure

For a defective sensor

- Replace the oxygen sensor with a compatible one

- Apply anti-seize paste on the sensor threads

- Tighten to the specified torque (usually 30–50 Nm)

For electrical issues

- Repair or replace the faulty wiring

- Clean corroded contacts

- Replace damaged connectors

Final testing

- Clear all fault codes

- Perform a road test to verify operation

- Monitor sensor parameters with the scanner

Estimated Costs

Repair costs vary by vehicle make and problem complexity:

- New oxygen sensor: 150–400 lei

- Diagnostic labor: 100–200 lei

- Wiring repairs: 50–300 lei

- Sensor replacement + labor: 250–600 lei

Prevention of Future Problems

To avoid a recurrence of code P0150:

- Use quality fuel

- Perform regular maintenance of the fuel system

- Replace the air filter according to the schedule

- Avoid operating with a near-empty fuel tank for extended periods

- Periodically check the condition of electrical connectors

Diagnosing the P0150 code correctly requires a methodical approach and solid technical knowledge. If you lack the necessary experience, we recommend consulting a specialized auto service for an efficient and durable repair.