- P0050 signals heater circuit issue in bank 2 sensor 1 O2 sensor

- Check engine light, rough idle, reduced fuel economy, possible black smoke

- Common causes: faulty heater, wiring, connectors, blown fuses; PCM faults rare

- Diagnosis requires scanner, multimeter, and careful step-by-step inspection before replacement

The P0050 trouble code is one of the most common OBD-II codes seen on modern vehicles, and it refers to an issue with the heater circuit of the oxygen sensor in bank 2, sensor 1. This problem can significantly affect engine performance and fuel economy, which is why quick and accurate diagnosis is essential.

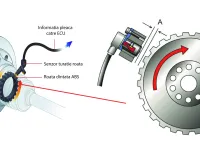

Integrated heated oxygen sensors play a crucial role in maintaining the optimal air-fuel mixture of 14.7:1, and they are among the most important sensors in the engine management system.

What the P0050 error code means

The P0050 code indicates a problem in the heater circuit of the oxygen sensor located on bank 2, sensor 1. This sensor sits upstream of the catalytic converter and monitors the oxygen level in the exhaust gases to optimize the air-fuel mixture.

The designation “B2S1” is interpreted as:

- B2 (Bank 2) — refers to the bank of cylinders that does not contain cylinder number 1

- S1 (Sensor 1) — the sensor upstream of the catalytic converter

Operating parameters and activation thresholds

Normal parameters

- Circuit resistance: approximately 8 ohms

- Permissible tolerance: maximum 10% variation in either direction

- Operating voltage: 12.6-13.8 volts (battery voltage)

- Response time: the sensor should become operational within a maximum of 8 seconds

Activation conditions

The PCM stores the P0050 code and illuminates the malfunction indicator lamp in the following situations:

- Circuit resistance exceeds ±10% tolerance

- Supply voltage does not meet normal parameters

- Sensor response remains constant for more than 8 seconds after engine start

Characteristic symptoms

Direct symptoms

- Check Engine light on the instrument cluster

- Rough engine operation at idle or under load

- Reduced fuel efficiency by up to 20%

- Black smoke emissions from the exhaust under certain conditions

Indirect symptoms

- Difficult engine start, especially when cold

- Slow throttle response

- Idle instability

- Emissions tests failing

Common causes of the P0050 code

Frequent causes

- Defective oxygen sensor — heater element failure

- Wiring problems — damaged wires, shorts, or corrosion

- Electrical connectors — corroded or disconnected contacts

- Blown fuses in the power supply circuit

Less common causes

- Defective PCM (very rare, under 5% of cases)

- Fuel pressure issues (too high or too low)

- Excessive vibrations that damage wiring

- Extreme temperatures affecting components

Common diagnostic mistakes

Many technicians make the mistake of automatically replacing oxygen sensors without a complete diagnosis. This can lead to:

- Unnecessary additional costs

- No resolution of the real problem

- Damage to other functional components

Recommendation: Always perform a full diagnosis before replacing components.

Detailed diagnostic guide

Preparation for diagnosis

Equipment needed:

- OBD2 scanner or code reader

- Digital multimeter with volt/ohm functions

- Manufacturer service manual

- Set of tools for disconnecting connectors

Diagnostic steps

Step 1: Visual inspection

Inspect all system components visually:

- Wiring — look for signs of damage, kinks, or abrasion

- Connectors — ensure they are firmly connected and free of corrosion

- Fuses — check continuity and physical condition

- Sensor — inspect for signs of physical damage

Step 2: Reading codes

- Connect the scanner to the OBD2 port

- Record all present and pending codes

- Note freeze frame data for context

- Clear the codes and test for recurrence

Step 3: Live data analysis

Monitor in real time:

- Sensor voltage (should fluctuate between 100-900 mV)

- Heater status (ON/OFF)

- Engine temperature and heating time

- Control loop (open/closed loop)

Step 4: Electrical testing

Heater resistance testing:

- Disconnect the sensor connector

- Measure resistance between the heater pins

- Normal value: 8Ω ± 10%

Power supply voltage testing:

- Check voltage at the wiring connector

- Normal value: 12.6-13.8V with the engine running

Continuity testing:

- Check continuity between the PCM and the sensor

- Look for opens or shorts

Step 5: Functional testing

Monitore sensor behavior under different conditions:

- Idle

- Under acceleration

- During deceleration

- After the engine reaches full operating temperature

Repair procedure

Common repairs

Replacing the oxygen sensor

- Check specifications — ensure you use the correct part

- Prepare the engine — allow it to cool for safety

- Disconnect the battery to prevent short circuits

- Remove the old sensor using the special wrench

- Apply anti-seize compound to the threads of the new sensor

- Install the new sensor following the specified tightening torque

Wiring repair

- Identify the defective point via continuity tests

- Remove the damaged section by about 5 cm in each direction

- Use quality connectors and heat-shrink tubing

- Protect the repair from heat and vibration

Final verification

After completing repairs:

- Reconnect all components

- Clear the error codes

- Start the engine and let it warm up

- Perform a test drive to verify operation

- Re-scan to confirm the issue has been resolved

Prevention tips

Preventive maintenance

- Replace oxygen sensors according to the maintenance schedule (80,000-160,000 km)

- Regularly check wiring in heat-prone areas

- Use high-quality fuel to minimize deposits

- Schedule periodic exhaust system inspections

Avoid problems

- Do not ignore the Check Engine light

- Avoid aggressive driving that can damage sensors

- Promptly repair engine problems that can affect sensors

- Use genuine or high-quality equivalent parts

Estimated repair costs

Indicative prices (RON)

- Original oxygen sensor: 200-600 lei

- Diagnosis labor: 50-150 lei

- Oxygen sensor replacement labor: 100-200 lei

- Wiring repair: 100-300 lei

Note: Prices vary by vehicle make and repair complexity.

Conclusion

The P0050 code requires a systematic approach for accurate diagnosis and durable repair. A solid understanding of the engine management system and a step-by-step diagnostic process will ensure effective problem resolution and prevent recurrence.

If you do not have experience diagnosing automotive electronics, we recommend consulting a qualified specialist to avoid further damage to the vehicle.