- Check engine light often appears with codes P0401, P0403, P0404, P0405/P0406

- Emissions tests fail due to higher NOx when EGR is faulty

- Fuel economy drops up to 10-15% in urban driving

- Power loss and slower acceleration due to improper exhaust gas recirculation

Modern emissions control systems have become increasingly complex, and the EGR (Exhaust Gas Recirculation) valve is a crucial component for meeting emissions standards. When this valve malfunctions, its effects are felt not only in the vehicle’s performance but also on the environment.

The EGR valve plays a key role in reducing harmful emissions by recirculating a portion of exhaust gases back into the combustion chamber. This technology not only protects the environment but also contributes to better engine efficiency.

What is the EGR Valve and How It Works

The EGR (Exhaust Gas Recirculation) valve is an emissions-control system that has become standard on most modern vehicles. Its operation is based on a simple but effective principle: capturing a portion of the exhaust gases and redirecting them to the intake manifold.

These exhaust gases, although already burned once, still contain fuel vapors that can be reused. The EGR valve allows these gases to mix with fresh air in the intake, reducing combustion temperature and, consequently, the formation of nitrogen oxides (NOx), the main pollutants targeted by this technology.

Control of the EGR valve is performed through the ECU (Electronic Control Unit), which analyzes various engine parameters such as coolant temperature, engine speed, and load to determine the timing and amount of gas that should be recirculated.

Symptoms of a Faulty EGR Valve

1. Check Engine Light Activation

The most common symptom of a faulty EGR valve is the activation of the engine warning light. Modern diagnostic systems are equipped with sensors that continuously monitor the EGR valve’s operation.

Error codes most frequently encountered include:

- P0401: Insufficient EGR flow

- P0403: EGR valve circuit fault

- P0404: EGR valve – circuit range/performanc

- P0405/P0406: EGR position sensor – signal low/high

These codes can be read with an OBD scanner and provide precise clues about the nature of the problem.

2. Emissions Test Failure (ITP)

A faulty EGR valve directly affects emissions levels. When it does not operate correctly, NOx emissions from the exhaust rise significantly, often exceeding legal limits.

During periodic technical inspections (ITP), vehicles with a faulty EGR valve will record elevated values in emissions tests. In extreme cases, authorities may temporarily suspend the vehicle’s documents if emissions exceed legal limits.

3. Increased Fuel Consumption

A functional EGR valve contributes to energy efficiency by reusing exhaust gases. When it fails, the engine compensates by injecting more fresh fuel to maintain the optimal air–fuel ratio.

This manifests as:

- 10-15% higher consumption in urban driving

- More frequent refueling

- Reduced range on the same tank

4. Reduced Engine Power

Faulty EGR operation affects the combustion process, resulting in a noticeable loss of power. This can appear as:

- Slower acceleration, especially in bursts

- Difficulties with overtaking

- The feeling that the engine isn’t pulling as before

- A greater need to press the accelerator pedal to achieve the same performance

Power loss can vary between 5-20%, depending on the extent of EGR valve damage.

5. Irregular Idle

At idle, the engine may not receive enough fuel for stable operation because the ECU expects the EGR valve to contribute part of the gases needed for the mixture. The result is unstable operation, evidenced by:

- Engine vibrations

- Uneven rpm

- Potential stalling

- Unusual sounds from the engine bay

EGR Valve Cleaning Procedure

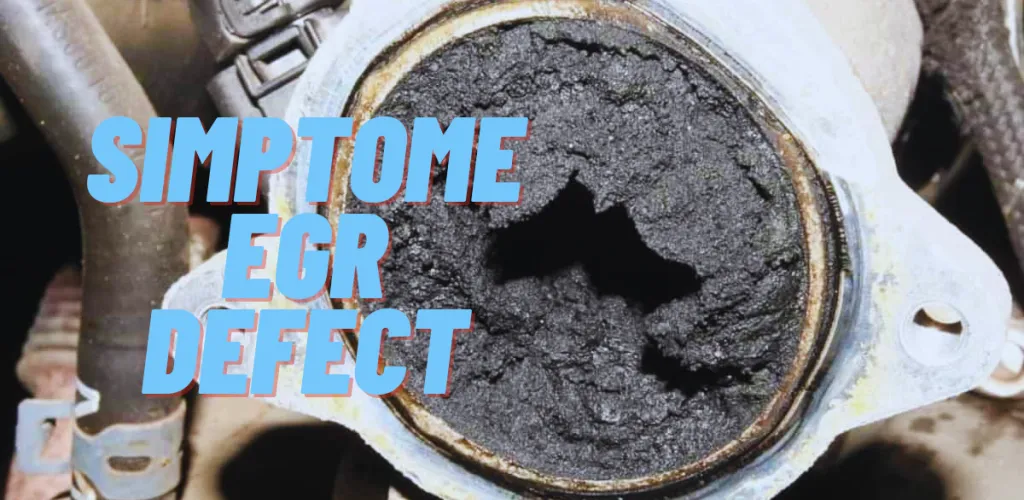

Before considering replacement, cleaning the EGR valve can resolve the issue in a high percentage of cases. Carbon deposits and fuel residues can partially or completely block the valve, mimicking a full defect.

Cleaning Method:

- Locating the valve: Usually situated between the exhaust manifold and the intake

- Disconnecting: Detach electrical cables and vacuum hoses

- Removing: Take off the mounting bolts

- Cleaning: Use carburetor spray or special cleaners designed to remove deposits

- Checking mobility: Test whether the valve plate moves freely

- Reassembly: Refit everything in the reverse order

Cleaning can extend the EGR valve life by 50,000–100,000 km, making it a high-yield investment.

Repair and Replacement Costs

Costs to repair an EGR valve vary considerably based on several factors:

Parts costs:

- Aftermarket EGR valve: 800-1,200 RON

- Original equipment EGR valve (OEM): 1,200-1,800 RON

- Additional sensors: 200-400 RON (if required)

Labor costs:

- Independent workshop: 200-400 RON

- Authorized service: 400-600 RON

- Time required: 2–4 hours depending on accessibility

Estimated total:

- Full replacement: 1,500-2,500 RON

- Professional cleaning: 150-300 RON

- Diagnostics: 100-200 RON

Factors affecting costs:

- Vehicle make and model

- EGR valve accessibility

- Need to replace adjacent components

- Geographic region and the service’s pricing policy

For premium vehicles or engines with complex configurations, costs can exceed standard values by 30–50%. Diesel vehicles also tend to have higher costs due to the EGR system’s complexity.

Preventing EGR Valve Failure

Maintaining the EGR valve in good working condition can be achieved through:

- Regular intake system maintenance

- Use of high-quality fuels with cleaning additives

- Avoiding frequent short trips at low RPMs

- Periodic checks of the crankcase ventilation system

- Timely replacement of the air and fuel filters

Proper preventive maintenance can extend the EGR valve life by up to 100,000 km compared to normal use.