- Diesel engines ignite fuel by compression, with no spark plugs.

- Combustion is gradual; injectors control burn duration per cycle.

- High RPM reduces mixing time, risking inefficient combustion; typical limit 4000–4400 RPM.

- Diesel offers high torque at low RPM, better efficiency, and durability.

Diesel engines are known for their lower rev limits compared to gasoline engines, a characteristic that stems directly from their operating principles.

This fundamental difference rests on the distinct combustion process and fuel-air mixture formation, crucial technical aspects for engine performance and efficiency.

Principle of operation of the diesel engine

Diesel engines operate on the principle of compression ignition, a process completely different from gasoline engines. In a diesel engine, ignition of the fuel-air mixture does not require a spark from spark plugs; it is achieved by injecting fuel directly into the combustion chamber, where the air is already compressed and heated.

Ignition is almost instantaneous thanks to the contact between the fuel and the compressed air, which reaches temperatures of about 500–700 °C. This high temperature is sufficient to initiate combustion without an external ignition source.

Combustion differences: diesel vs gasoline

Unlike gasoline, which is ignited almost instantly by an electric spark, the diesel combustion process presents distinct characteristics. Diesel combustion occurs gradually over a longer period.

This difference arises because injectors spray the fuel over a well-defined and controlled period set by each manufacturer. The result is a prolonged burn in diesel engines, compared with the near-instantaneous burning of gasoline engines.

Consequences of increasing RPM in diesel engines

- Insufficient time for fuel–air mixing: At high RPM, the time available for optimal mixing of diesel with air decreases substantially

- Inefficient burning: The mixture will continue to burn across the entire piston stroke, resulting in uncontrolled combustion

- Reduced performance: Poor combustion leads to reduced power and fuel economy

- Increased mechanical stress: Engine components are subjected to higher stresses

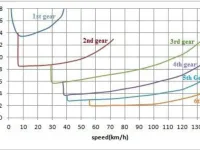

Practical RPM limits

For these technical reasons, diesel engines are typically electronically limited to around 4000-4400 RPM. This limit is not arbitrary; it is a protective measure that ensures:

- Efficient operation of the combustion process

- Maintaining fuel efficiency

- Protecting mechanical components

- Reducing pollutant emissions

Compensatory advantages of diesel engines

- High torque at low RPM

- Superior fuel efficiency

- High durability

- Excellent performance at steady cruising

These characteristics explain why diesel engines remain a preferred choice for commercial vehicles, large SUVs, and applications that require high torque at low RPM.