- Preventive maintenance lowers long-term costs and extends truck life.

- Up-to-date technical files guide efficient maintenance and track history.

- Adhere to scheduled service intervals using fleet management software.

- Newer trucks generally cost less to operate than older, used ones.

Any transportation company aims to optimize its business by reducing costs without compromising quality of work. Preventive maintenance of trucks is one of the most effective ways to reduce expenses in the long term. In this article, we present four essential rules that can have a significantly positive impact on the growth of your business.

Probably the first aspect that influences operating costs is the condition of the vehicles owned by the company. A new truck will have lower transport costs than a truck that already has several years of heavy use on its record. We can attribute this not only to the advanced technology of new trucks, which evolves year after year, but also to the general condition and maintenance history of the truck in question.

Why preventive maintenance is essential

Not every transport company can afford to replace its fleet with new vehicles. They need an effective method to reduce costs through regular and professional maintenance of the older ones. Every transport company, sooner or later, if it wants to stay competitive in the market, must adopt clear rules that enable it to reduce operating expenses.

Truck maintenance is not just about repairing something that has failed. It is a long-term strategy that will yield positive effects over time. The strategy aims to reduce wear on parts and extend the life of components and mechanisms.

The 4 basic rules for truck maintenance

1. Maintain an up-to-date technical file for each vehicle

The technical file is an essential reference guiding us when planning regular and efficient maintenance for a vehicle. It must contain every change or repair performed on the truck, from minor services to major repairs.

The technical file is very useful as a reference when scheduling periodic changes of oils, fluids, and filters. It also provides an overview of the vehicle’s history, helping identify recurring problems or components requiring special attention.

We can use specialized software to track each vehicle: kilometers driven, overall consumption, inspections performed, parts replaced, etc. From these statistics we draw conclusions and understand where improvements are needed so the vehicle operates better and more efficiently.

2. Perform the periodic service on time

Respect the manufacturer’s recommended service intervals with scrupulous adherence. Replace consumables, fluids, and oils on time according to technical specifications. Using a fleet management software increases efficiency and punctuality in scheduling periodic checks.

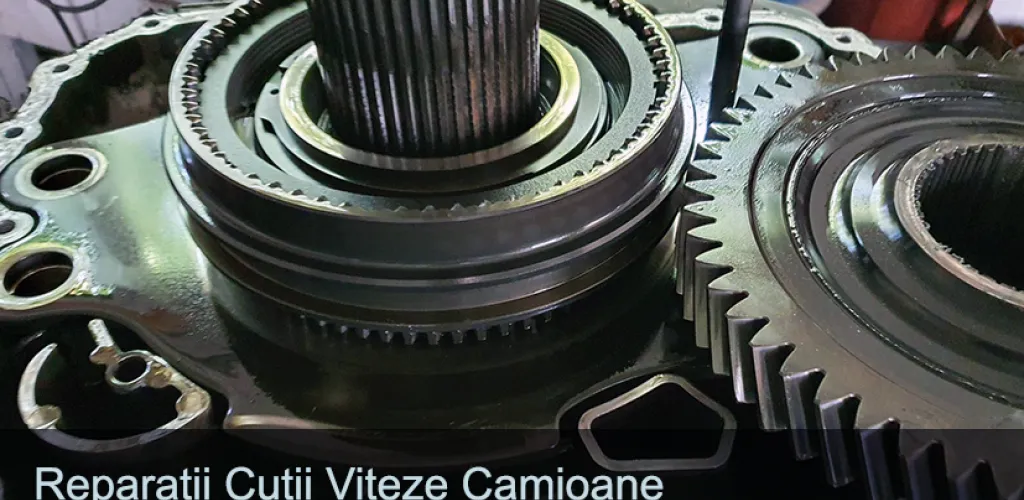

Preventive maintenance for a vehicle will always be cheaper than repairing a serious fault. For example, changing the transmission oil when it has lost its properties can significantly reduce wear on the gears, extending their life and avoiding costly repairs.

But we all know that keeping track of what must be done is not enough; we must actually perform these revisions and adhere to the established schedule. Postponing services can lead to chain failures and exponentially higher costs.

3. Choose a trusted truck service

A trusted truck service, oriented toward the client’s benefits, can be the most important link in your business. For more difficult repairs, it’s best to call on specialists even if they live in another city. For manual transmission repairs, it is more important that the service you collaborate with is trustworthy and works well than the distance to this service.

Distance to a service is no longer a problem today. The fast courier system is so well developed that you can easily send a transmission unit to a trusted specialist. The important thing is that the repair is done quickly, professionally, and with quality parts.

Look for a service partner who:

- offers warranty for the work performed

- has experience with your truck’s make and model

- uses modern diagnostic equipment

- communicates transparently about estimated costs

- respects the established deadlines

4. Use high-quality replacement parts for repairs

Sooner or later, you will surely need repairs. Parts wear out over time and need to be replaced. In this case it is essential to choose high-quality replacement parts that will perform well for a long time after repair.

Poor-quality parts wear out faster and can affect other components they interact with, causing major truck failures and additional costs. Investing in an original or quality-equivalent part pays off through durability and reliability.

Pay careful attention to tires

Last but not least, pay close attention to the truck’s tires. A high-quality set of truck tires, season-appropriate, significantly contributes to safety and transport efficiency.

Check regularly:

- Tread wear

- Tire pressure (cold)

- Damage or cuts

- Tread depth (minimum legal 1.6 mm)

Replace them on time to prevent unpleasant road incidents and to maintain optimal fuel consumption.

Conclusion

Once we establish a preventive maintenance program and apply it with discipline, we have a strong chance of significantly reducing our vehicle repair costs. The investment in preventive maintenance is always smaller than the cost of major repairs or, worse, downtime caused by unexpected failures.

By applying these four essential rules, your transport company will benefit from a more reliable fleet, lower operating costs, and increased competitiveness in the market.

sursa foto: cutiivitezezf.ro