- Recognize warning signs like unusual noises, vibrations, or power changes.

- Engine won’t start due to battery, fuel/ignition, or mechanical faults.

- Overheating is dangerous; stop immediately and seek specialized service.

- Oil issues: increased consumption from worn piston rings, valve guides, leaks, turbocharger issues.

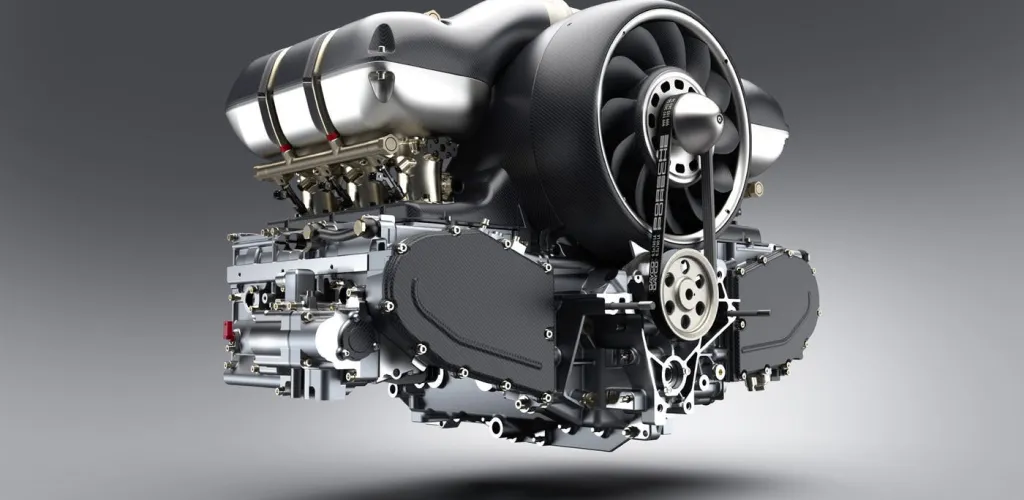

The engine is the heart of any vehicle, and problems at this level can turn a simple trip into an expensive nightmare. Knowing the warning signs and the most common faults can make the difference between a minor repair and a full engine replacement.

Without proper maintenance and attention to the symptoms that appear, minor issues can quickly escalate into major failures. Early diagnosis and preventive measures are the key to keeping the engine running optimally and avoiding substantial costs.

The Importance of Recognizing Warning Signs

Rapid recognition of engine problems can prevent serious and costly failures. Any change in the car’s behavior — unusual noises, vibrations, changes in power or throttle response — may indicate developing issues.

The difference between a minor issue and a major failure often lies in how quickly you react to the first signs. An engine that starts running irregularly won’t fix itself — on the contrary, problems will progressively worsen until complete failure.

Engine Won’t Start

Battery problems

When the battery is the main cause, the engine will emit a characteristic click or will struggle to start but fail. Check:

- Battery terminals for corrosion

- Battery charge level

- Integrity of power cables

Fuel supply or ignition problems

The car will crank normally but won’t start fully. Causes include:

- Defective fuel pump or clogged fuel filter

- Worn spark plugs or dirty injection systems

- Problems in the electronic ignition system

- ECU or vital sensor failures

Mechanical problems

- Defective starter or faulty starting relay

- Problems in the timing/distribution system

- Insufficient compression in cylinders

- Issues in the fuel delivery system

Engine Overheating

Overheating is one of the most dangerous situations for the engine. Excessive temperatures can cause permanent deformation of metal components and irreversible failures.

Main Causes

- Low coolant level: Regularly check the level and top up as needed

- Clogged radiator: Deposits and impurities can block coolant flow

- Stuck thermostat: A defective thermostat can impede normal circulation

- Defective water pump: Without forced circulation, cooling becomes inefficient

- Non-functioning cooling fan: Essential for cooling at low speeds

- Compromised head gasket: Can cause pressure leaks and mixing of fluids

Emergency measures

Do not continue driving with an overheated engine! Stop the vehicle immediately in a safe place, shut off the engine, and contact a specialized service. Driving with an overheated engine can cause damage worth thousands of euros.

Engine Oil Problems

Engine oil provides essential lubrication and protection against wear. Neglecting this aspect can lead to complete engine seizure.

Common oil problems

Increased oil consumption:

- Worn piston rings allow oil to pass into the combustion chamber

- Worn valve guides

- External leaks through degraded gaskets

- Turbocharger issues (on turbocharged engines)

Degraded oil:

- Late changes lead to oxidation and sludge formation

- Old oil loses lubricating properties

- Deposits accumulate in oil passages

- Metal particles accelerate wear

Maintenance recommendations

- Adhere to oil change intervals (7,500-15,000 km depending on specifications)

- Use only the oil recommended by the manufacturer

- Check the level weekly with the car on level ground

- Monitor the oil color and consistency

- Consider synthetic oils for superior performance

Cooling System Problems

The cooling system maintains the engine’s optimal operating temperature. Coolant not only absorbs heat but also protects against freezing and corrosion.

Antifreeze issues

- Incorrect concentration: Insufficient protection at extreme temperatures

- Age: Degraded coolant loses anti-corrosion properties

- Contamination: Impurities affect heat transfer

- Leaks: Gradual loss reduces system efficiency

Signs of degraded coolant

- Color change (rusty, brown)

- Presence of suspended particles

- Sharp or unusual odor

- Foaming or air bubbles

- Viscous deposits in the expansion tank

Recommended replacement interval: 3-5 years or 50,000-100,000 km, depending on the type of antifreeze used.

Irregular Engine Operation

A car that hesitates, stalls suddenly, or runs irregularly presents a real road-safety risk and points to developing issues.

Characteristic symptoms

- Unexpected stalls while driving

- Idle speed fluctuations

- Loss of power when accelerating

- Intermittent or irregular running

- Delayed throttle response

- Increased fuel consumption

Possible causes and solutions

Fuel system problems:

- Clogged fuel filter – replacement required

- Weak fuel pump – fuel pressure testing

- Dirty injectors – professional cleaning

- Contaminated fuel tank – draining and cleaning

Ignition system problems:

- Worn or dirty spark plugs – periodic replacement

- Faulty ignition coils – individual testing

- Damaged ignition cables – check continuity

Sensors and electronic systems:

- Camshaft position sensor

- Mass Air Flow (MAF) sensor

- Manifold Absolute Pressure (MAP) sensor

- Oxygen sensor (lambda)

- ECU problems

Diesel Engine-Specific Problems

Diesel engines have peculiarities requiring special attention, especially in the fuel injection system.

Injector problems

Diesel injectors operate at very high pressures (1,500-2,500 bar) and are sensitive to fuel quality.

Causes of failure:

- Poor fuel quality with impurities

- Water in the fuel system

- Clogged fuel filter or late changes

- Normal wear due to high pressures

Symptoms:

- Increased fuel consumption (20-30%)

- Noticeable loss of power

- Abundant black smoke on acceleration

- Metallic knocking sounds from the engine

- Difficult starting, especially in winter

- Irregular idle

Preventive measures for diesel engines

- Fuel exclusively from trusted stations

- Regular fuel filter changes

- Use of cleaning additives every 10,000 km

- Avoid small, frequent fueling

- Let the engine warm up before demanding accelerations

Smoke and Steam – Diagnosis by Color

Exhaust smoke or engine bay steam provides valuable clues about existing problems.

White smoke

Causes:

- Coolant entering the combustion chamber (head gasket)

- Normal condensation in winter (disappears after warming up)

- Diesel injector issues

- Cracks in the head or block

Blue smoke

Causes:

- Burning engine oil in the combustion chamber

- Worn piston rings

- Degraded valve guides

- Turbocharger problems

- Block crankcase ventilation blocked

Black smoke

Causes:

- Too rich fuel mixture

- Clogged air filter

- Defective or misadjusted injectors

- Defective turbocharger

- Restricted exhaust system

Yellow/Green smoke

Causes:

- Coolant leaks onto hot engine components

- Antifreeze evaporating from the exhaust manifold

- Serious cooling system problems

Unusual Noises – Diagnostic Guide

A well-maintained engine operates relatively quietly and without excessive vibrations. Unusual noises almost always indicate developing issues.

Metallic knocking

At acceleration:

- Worn connecting rod bearings (rhythmic noise tied to RPM)

- Worn crankshaft bearings (deep knocks)

- Piston or ring problems

- Excessive play in the timing mechanism

At idle:

- Worn engine mounts

- Injection system problems

- Detonation (uncontrolled ignition)

Accessory noises

- Incorrect belt tension: squealing on startup

- Faulty alternator: continuous noise increasing with RPM

- Air conditioning compressor: noise only when AC is on

- Water pump: noise worsening with temperature

- Cooling fan: intermittent noise

Exhaust system noises

- Leaking exhaust: loud noise, especially on acceleration

- Damaged catalytic converter: metallic rattling noise

- Loose exhaust system: very loud noise

Water Ingress into the Engine

Water in the engine can cause instant and irreversible damage. The phenomenon known as “hydrolock” occurs when water enters the combustion chamber.

How infiltration occurs

- Driving through water deeper than 20-30 cm

- Water enters through the intake system (air filter)

- Reaches the combustion chamber where it cannot be compressed

- Pistons seize, potentially causing bent rods or other component damage

Risks and consequences

- Complete hydrolock: engine blocks instantly

- Internal component damage: bent or broken connecting rods

- Electrical problems: sensor and wiring short circuits

- Accelerated corrosion: water speeds up oxidation

- Oil contamination: lubrication properties are lost

Prevention and reaction measures

Prevention:

- Avoid driving through deep water

- Use alternate routes during floods

- Check weather forecasts before long trips

In case of infiltration:

- Do not attempt to start the engine!

- Contact a roadside service immediately

- Inform the service about possible water intrusion

- Request a full inspection before attempting to start

Timing System Problems

The timing system synchronizes valve movement with pistons. A problem here can cause catastrophic damage.

Critical components

- Timing belt/chain: synchronizes crankshaft rotation with the camshaft

- Tensioners and pulleys: maintain correct tension

- Camshaft: controls opening and closing of the valves

- Valves: control intake and exhaust of gases

Symptoms of problems

- Metallic noises from the top of the engine

- Progressive loss of power

- Increased fuel consumption

- Unusual vibrations, especially at idle

- Irregular operation

Consequences of failure

On interference engines (most modern engines):

- Bent or broken valves

- Damaged pistons

- Possible head gasket cracks

- Need for a complete engine rebuild

- Costs can exceed the vehicle’s value

Replacement interval varies between 60,000-120,000 km, depending on the manufacturer and engine type.

Differences Between Gasoline and Diesel Engines

Gasoline engine characteristics

Advantages:

- Easier cold starts

- Quieter and smoother operation

- Lower maintenance costs

- More affordable spare parts

- Lower particulate emissions

- Quicker throttle response

Disadvantages:

- Lower durability (150,000-250,000 km)

- Higher fuel consumption (15-20%)

- Higher oil consumption at high mileage

- Lower torque at low RPM

- Higher fuel costs

Specific problems:

- Piston ring wear requiring replacement at 20,000-40,000 km

- Sensitivity to gasoline quality

- Detonation (autoignition) issues

- Faster wear of piston rings

Diesel engine characteristics

Advantages:

- Superior durability (250,000-500,000 km)

- 20-30% lower consumption

- Higher torque at low RPM

- Better energy efficiency

- Lower fuel costs

- Lower CO2 emissions

Disadvantages:

- Harder starting at low temperatures

- Higher noise and vibrations

- Higher repair costs

- Sensitivity to fuel quality

- Higher emissions of particulates and NOx

- Need to warm up before heavy loads

Specific problems:

- Injectors require special attention

- Issues with the particulate filter (DPF)

- Sensitivity to diesel fuel waxing

- Turbocharger problems at high mileage

Preventive Maintenance Programs

Daily/Weekly checks

- Oil level: check with the dipstick when the engine is cold

- Coolant level: in the expansion tank

- Visible leaks: oil, coolant, fuel

- Unusual noises: at startup and during operation

- Exhaust smoke: color and intensity

- Starting behavior: ease of starting

Monthly checks

- Battery: clean terminals, check charge

- Belts: tension, cracks, wear

- Air filter: level of dirt

- Fluid levels: brake, steering, windshield washer

- Tires: pressure and wear

- Lighting operation: phases, position, indicators

Semi-annual checks

- Coolant (antigel): concentration and color

- Cooling system: leaks, thermostat operation

- Spark plugs (gasoline) or glow plugs (diesel): general condition

- Exhaust system: cracks, corrosion

- Clutch: engagement point, operation

- Air conditioning system: efficiency, leaks

Scheduled service intervals

At 15,000 km or once a year:

- Change oil and oil filter

- Complete engine inspection

- Computer diagnostics

- Inspect timing/distribution system

- Emissions check

- Fuel system check

At 30,000 km:

- Replace air filter

- Replace fuel filter

- Check spark plugs (gasoline)

- Inspect exhaust system

- Check turbocharger

At 60,000-120,000 km:

- Replace timing belt/chain

- Change coolant

- Inspect and potentially replace injectors

- Check engine compression

- Check water pump

Estimated Repair Costs

Minor repairs (150-800 lei)

- Spark plug replacement: 150-300 lei

- Replace air filter: 100-200 lei

- Replace fuel filter: 200-400 lei

- Minor leak repairs: 300-800 lei

- Replace thermostat: 400-700 lei

- Replace simple sensors: 200-600 lei

Medium repairs (800-4000 lei)

- Replace water pump: 800-1500 lei

- Cooling system repairs: 1000-2500 lei

- Injector cleaning: 600-1200 lei

- Replace ignition coils: 800-1600 lei

- Exhaust system repairs: 500-2000 lei

- Replace timing belt: 1500-4000 lei

Major repairs (4000+ lei)

- Diesel injector replacement: 4000-12000 lei

- Head gasket repairs: 3000-8000 lei

- Engine rebuild: 8000-25000 lei

- Turbocharger replacement: 3000-8000 lei

- New or used engine: 5000-30000 lei

Prices vary depending on the vehicle make, model, and repair complexity.

Warning Signs Requiring Immediate Attention

Dashboard warning lights

- Check Engine: problems in the engine management system

- Temperature: risk of overheating

- Oil pressure: risk of engine seizure

- Battery: issues with the charging system

- Particulate filter (diesel): requires regeneration

Critical mechanical symptoms

- Loud metallic noises: stop the engine immediately

- Sudden loss of power: urgent inspection

- Prominent colored smoke: do not continue driving

- Overheating: stop immediately in a safe place

- Smell of burnt oil: fire risk

Abnormal behavior

- Unexpected stalls: safety risk

- Severe vibrations: serious developing issues

- Sudden fluid loss: major liquid loss

- Inability to start: complex inspection required

Choosing the Right Service Center

Selection criteria

- Specialization for your make: knowledge of specifications

- Modern diagnostic equipment: compatible scanners

- Certified technicians: ongoing training

- Original or equivalent parts: guaranteed quality

- Warranty on work: confidence in services

- Reputation and references: experiences of other customers

Important questions for the service

- What is your experience with my make/model?

- What diagnostic equipment do you use?

- Do you offer warranty on work and parts?

- What are the estimated costs and time?

- Can you provide a detailed estimate?

- Do you use original or aftermarket parts?

Conclusion and Final Recommendations

Preventive engine maintenance is not just a cost issue—it’s an investment in your safety and that of your passengers. A well-maintained engine lasts longer and delivers consistent performance and optimized fuel consumption.

Most serious engine problems can be avoided by:

- Respecting the manufacturer’s maintenance schedule

- Paying attention to warning signs and acting promptly

- Using quality consumables (oil, filters, fuel)

- Driving responsibly without subjecting the engine to extreme cold starts or heavy loads

- Regular service by specialists equipped with high-end diagnostic tools

Remember that a preventive check costs far less than an emergency repair. The investment in proper maintenance pays off through:

- Increased engine durability

- Optimized fuel consumption

- Higher resale value

- Greater road safety

- Avoiding the costs of major repairs

Final recommendation: treat the engine with respect, and it will give you hundreds of thousands of kilometers of reliable service. Ignoring warning signs can turn a minor problem into a major failure that costs more than the car’s value.