- Timing ensures piston-valve synchronization across the four-stroke cycle.

- A timing kit comprises belt/chain, pulleys, tensioner, water pump, gears, and more.

- Timing belts are cheaper and quieter but need replacements every 60k–100k km.

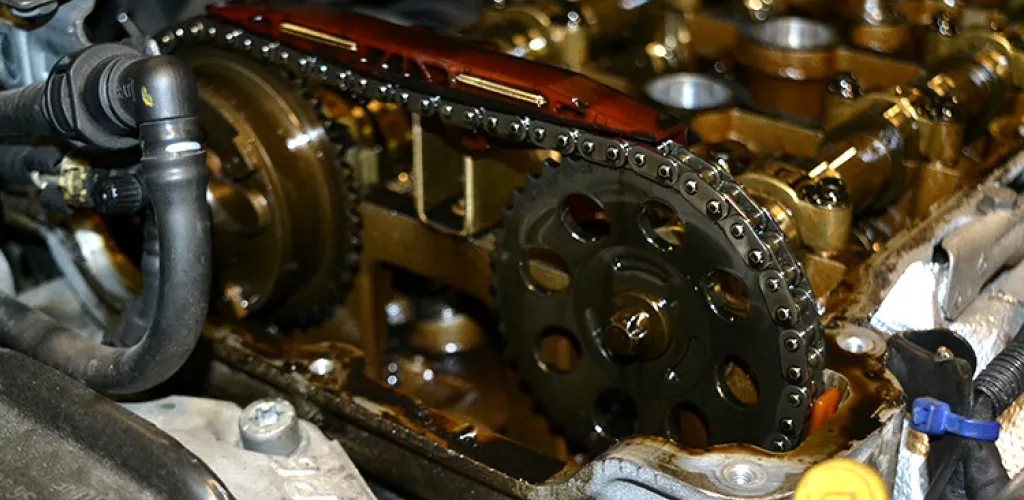

- Timing chains offer durability and long service intervals but can be noisier.

Timing is one of the most critical components of an internal combustion engine, responsible for perfect synchronization between the crankshaft and the camshafts. Without it, the engine cannot operate correctly, and a failure can cause major damage that could cost thousands of euros.

In this comprehensive guide, you’ll discover everything you need to know about timing: how it works, the types available on the market, warning signs indicating the need for replacement, and the consequences of a failure. This knowledge will help you keep your car in optimal condition and avoid costly repairs.

What is the timing system and what is its role in the engine

The timing, also known as the timing kit, represents the set of components that ensure synchronization between piston movement and the opening/closing of the valves. This system coordinates precisely when intake and exhaust valves open relative to the piston position in the cylinder.

Correct timing operation is essential to respect the four strokes of the engine: intake, compression, power, and exhaust. Any desynchronization can lead to reduced performance, higher fuel consumption, or even irreversible damage.

Components of the timing system

A complete timing kit includes the following elements:

- The timing belt or timing chain – the main element that transmits motion

- Guiding pulleys – keep tension and the correct trajectory

- Tensioner – can be mechanical or hydraulic, adjusts tension

- Water pump – in most modern vehicles it is driven by the timing system

- Gears and sprockets – ensure precise transmission of motion

- Air relief valve – in certain configurations

Types of timing systems: advantages and disadvantages

Belt-driven timing

The timing belt was widely adopted in the auto industry starting in the 1960s, when Pontiac introduced the first six-cylinder engine equipped with this drive type. Initially, all engines used metal chains, but belt advantages led to widespread adoption.

Advantages of belt-driven systems:

- Lower production and replacement costs

- Quiet operation due to the elastic material

- Minimal vibrations transmitted to the body

- Easier replacement access

- Fewer damages on belt break (in non-interference engines)

- Lighter overall assembly

Disadvantages of the timing belt:

- Shorter replacement intervals (60,000–100,000 km)

- Sensitivity to extreme temperatures

- Deterioration over time even with use

- Mandatory periodic checks

- Risk of sudden break without warning

Timing chain system

After a period of belt dominance, the 1990s marked the return of timing chains, especially on premium and performance engines. Manufacturers improved the technology, making chains lighter and more efficient.

Advantages of the chain system:

- Exceptional durability (250,000–300,000 km for classic chains)

- Superior resistance to mechanical stress

- No need for frequent planned replacements

- Independent water pump (in most configurations)

- Consistent performance over the long term

Disadvantages of the timing chain:

- Higher initial cost

- Louder operating noise

- Complexity of hydraulic tensioner

- More severe damage in case of failure

- Issues with the tensioner at cold starts

- Sensitivity to oil quality

Common problems with modern chains: VW Group’s TSI engines and some BMW diesels are known for premature hydraulic tensioner failure. The tensioner may not receive oil pressure immediately at startup, allowing the chain to slacken and vibrate, accelerating wear.

Timing gear (pinion) systems

This timing type uses a complex arrangement of metal gears to transmit motion from the crankshaft to the camshafts.

Specific characteristics:

- Maximum durability – can run for the life of the engine

- Robust construction without needing a tensioner

- Used on Ferrari engines and some VW 2.5 TD/TDI engines

- High production cost

- Repair complexity

Mixed timing systems

Some engines combine different drive types: for example, chain to drive the camshafts and belt for the water pump or other accessories. This approach tries to balance the advantages of each system.

Interference versus non-interference engines

This classification is fundamental to understanding the risks associated with timing failure.

Interference engines

In these engines, the maximum piston travel overlaps with the maximum valve opening. If the timing fails and the valves stay open when the piston rises, they will collide.

Typical consequences:

- Bent or broken valves

- Damaged valve seats

- Cracked or pitted pistons

- Bent connecting rods

- Cylinder head cracks

- In extreme cases, engine block damage

Non-interference engines

These engines are designed with enough clearance between pistons and valves that even if the timing fails, components will not collide.

Advantages:

- Minimal damage on timing failure

- Only timing components need replacement

- Lower repair costs

- Minimal risk of collateral damage

Symptoms of a worn timing system

Specific signals for the timing belt

Visual inspection:

- Cracks on the belt sidewall

- Wear or missing teeth

- Visible fibers from the inner reinforcement

- Hardening or cracking of the material

- Deformations of the tooth profile

Auditory symptoms:

- High-pitched engine noises

- Squealing on acceleration

- Metallic sound from worn pulleys

Indicators for the timing chain

Characteristic noises:

- Metallic rattling on cold start

- Maraca-like sound at idle

- Noise disappears after the engine warms up

- Nose intensifies on acceleration

Other symptoms:

- Idle vibrations

- Hard starting

- Engine timing misalignment

Common symptoms for both types

- Starting problems: engine hard to start or won’t start

- Reduced performance: loss of power and torque

- Increased consumption: fuel and oil usage

- Unusual vibrations: especially at idle

- Exhaust smoke: indicator of incorrect synchronization

Replacement intervals

For the timing belt

Normal operating conditions:

- Standard interval: 80,000–100,000 km

- Time limit: maximum 6 years

- Our recommendation: 80,000 km for maximum safety

Severe conditions:

- Heavy urban traffic

- Extreme temperatures

- Frequent short trips

- Recommended interval: 60,000 km or 4 years

For the timing chain

Classic chains (pre-2000):

- Durability: 250,000–300,000 km

- Some exceed 500,000 km

- Annual check after 200,000 km

Modern chains:

- Reduced durability: 150,000–200,000 km

- Mandatory check after 100,000 km

- Preventive replacement recommended

Consequences of timing system failure

Belt failure

Belt failure typically occurs without prior warning. You’ll hear a bang from the engine compartment, followed by sudden engine stoppage.

In interference engines:

- Repair costs: 2,000–8,000 RON

- Repair time: 1–3 weeks

- Risk of complete engine replacement

In non-interference engines:

- Costs: 800–2,000 RON

- Only timing replacement needed

- Repair in 1–2 days

Timing chain failure

The chain stretches gradually, but final failure can be catastrophic.

Typical damage:

- Cracked or broken engine block

- Severely damaged cylinder head

- Bent crankshaft

- Costs: 5,000–15,000 RON

- Often requires engine replacement

Belt vs chain: how to choose the best option

We recommend the belt if:

- You drive under 15,000 km annually

- You prefer predictable maintenance costs

- You want quiet operation

- You have access to specialized service

- Your car is used under normal conditions

We recommend the chain if:

- You drive over 20,000 km annually

- Long-term durability is a priority

- You don’t mind the higher initial investment

- You drive in severe conditions

- You want longer intervals between services

Brands and manufacturers we recommend

Premium timing belts

Continental ContiTech:

- OEM standard for Audi, BMW, Mercedes

- HNBR technology for increased durability

- Extended warranty

- Price: 150–400 RON

Bosch:

- Excellent price-performance ratio

- Used as original equipment

- Wide availability

- Price: 100–300 RON

Gates:

- World leader in drive belts

- Complete kits with all accessories

- Price: 200–500 RON

Auxiliary components

Pulleys and tensioners:

- INA (Schaeffler): German technology, maximum durability

- SKF: Nordic standard, very reliable

- FAG: premium performance for sports cars

Water pumps:

- HEPU: German specialist in cooling pumps

- Graf: innovative technology used in OEM

- Febi Bilstein: German quality at competitive price

Timing chains

Iwis:

- OEM supplier for BMW, Mercedes, Audi

- Advanced manufacturing technology

- Maximum durability

- Price: 400–1,200 RON

Febi Bilstein:

- Consistent German quality

- Complete kits

- Price: 600–1,500 RON

Replacement costs in 2024

Timing belt - complete estimates

Small cars (Dacia, Skoda, VW up!):

- Parts: 300–500 RON

- Labour: 400–600 RON

- Total: 700–1,100 RON

Medium cars (Golf, Passat, Octavia):

- Parts: 500–800 RON

- Labour: 600–1,000 RON

- Total: 1,100–1,800 RON

Premium cars (BMW, Mercedes, Audi):

- Parts: 800–1,500 RON

- Labour: 1,000–2,000 RON

- Total: 1,800–3,500 RON

Timing chain costs - detailed

Small engines (1.0–1.4 TSI):

- Parts: 800–1,500 RON

- Labour: 800–1,200 RON

- Total: 1,600–2,700 RON

Medium engines (1.6–2.0 TSI/TDI):

- Parts: 1,200–2,000 RON

- Labour: 1,200–1,800 RON

- Total: 2,400–3,800 RON

Large engines (V6, V8):

- Parts: 2,000–3,500 RON

- Labour: 2,000–3,000 RON

- Total: 4,000–6,500 RON

Practical maintenance tips for the timing system

Planning replacement

- Document history – keep receipts and records

- Schedule ahead of time – don’t wait for the last kilometer

- Choose the right timing – avoid vacations and peak periods

- Budget comprehensively – include auxiliary components

Periodic checks

For belts:

- Visual inspection at every service

- Check tension at 20,000 km

- Monitor for suspicious noises

- Watch for leaks around the belt area

For chains:

- Listen for noises on cold starts

- Check engine oil quality

- Monitor oil consumption

- Watch for unusual vibrations

Choosing the service provider

Important criteria:

- Specialization for your make

- Modern diagnostic equipment

- Warranty on work of at least 1 year

- Use of original or equivalent parts

- Positive references from other customers

Common mistakes to avoid

When buying a used car

- Do not accept verbal statements about timing being “recently changed”

- Request documentary proof (invoices, service book)

- Check the maintenance history

- If in doubt, budget for replacement

During maintenance

- Do not postpone replacement to save money

- Do not choose unknown parts to reduce costs

- Do not ignore noises from the engine area

- Do not attempt DIY timing repairs

- Do not neglect auxiliary components (water pump, tensioners)

During vehicle use

- Do not thrash the engine when cold

- Do not skip scheduled inspections

- Do not use questionable oil

- Do not exceed recommended intervals

Future technologies in the timing domain

Electronic systems

Some manufacturers are experimenting with electronically controlled variable timing systems that can adjust valve opening times based on driving conditions.

Advanced materials

Modern belts use HNBR (hydrogenated nitrile rubber) compounds that offer superior resistance to temperature and wear.

Monitoring sensors

Modern systems include sensors that continuously monitor the timing system’s status and alert you when replacement is needed.

The timing system is one of the most critical engine components, and correct maintenance is essential for optimal performance and vehicle longevity. Regardless of the system type—belt or chain—adhering to service intervals and using quality parts are investments that pay off with years of trouble-free operation.

For any questions about your car’s timing system, consult the owner’s manual and contact a specialized service. This component leaves no room for compromise—the safety and reliability of the vehicle largely depend on it.