- Oil pressure warning light means check oil level and top up promptly.

- If light stays on after topping up, stop the engine immediately.

- Low oil pressure causes abnormal readings and rough engine operation.

- Overheating and unusual noises signal lubrication failure and potential engine seizure.

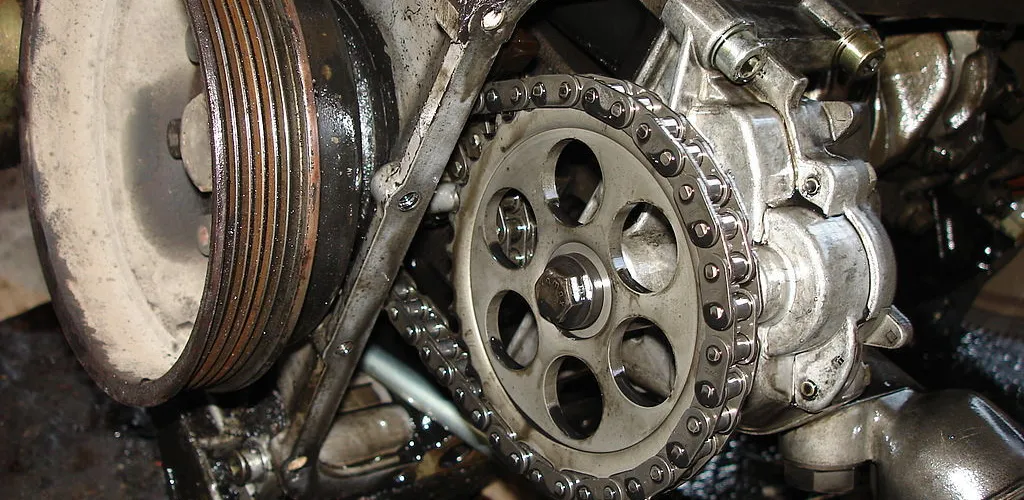

The oil pump is one of the engine’s vital components, responsible for circulating oil through the entire lubrication system. While failures of this component are relatively rare, the consequences of a faulty oil pump can be devastating for the engine, leading to costly damage or even complete engine seizure. Any driver should know the symptoms of an oil pump that isn’t functioning properly and know what measures to take in such situations.

The oil pump plays the essential role of delivering the necessary oil flow in the circuit, maintaining the optimal pressure for lubricating all moving parts in the engine. Without proper operation of this component, the engine risks irreversible damage in a very short time.

How to recognize a faulty oil pump

Oil light on the dashboard

The first and most obvious sign of a problem with the oil pump is the illumination of the red oil pressure warning light on the instrument cluster. This light should never be ignored or considered a minor issue.

However, lighting up this warning does not exclusively indicate a pump failure. It can also signal other problems such as:

- Oil pressure in the engine low for various reasons

- Oil leaks that cause the level to drop

- Degraded or overly viscous oil

- Clogged oil filter

The first thing to do when this light comes on is to check the oil level with the dipstick. If the level is below minimum, urgently top up with oil of the same specification to the proper level.

What to do if the light stays on after topping up the oil

If after checking and topping up the oil the light remains on, there is a high probability that the oil pump has issues. In this situation, stop the engine immediately and do not continue driving the vehicle.

Symptoms of a faulty oil pump

Low oil pressure

A defective pump cannot deliver the required flow to maintain the optimal oil pressure in the circuit. This condition is manifested by:

- Constant oil warning light

- Abnormal readings on the oil pressure gauge (if equipped)

- Irregular engine operation

Low oil pressure means engine parts are not lubricated properly, which accelerates wear and can lead to engine seizure.

Engine overheating

Engine oil plays a crucial role in temperature control, removing heat from critical areas and reducing friction between parts. When the pump does not function correctly:

- Engine temperature rises abnormally

- The temperature warning light may come on

- The engine may enter thermal protection mode

- Increased risk of cylinder head cracking or piston seizure

Prolonged overheating can cause:

- Cylinder head warping

- Piston seizure in the cylinders

- Damage to cylinder head gaskets

- Cracking of the engine block in extreme cases

Abnormal engine noises

Lack of proper lubrication causes engine components to produce characteristic noises:

- Metallic knocking – originates from engine bearings that are no longer properly lubricated. These are serious noises indicating accelerated wear.

- Ticking noises – may originate from:

- Hydraulic valve lifters

- High-pressure oil pumps (in modern diesel engines)

- Timing chain systems

- Rubbing noises – occur when metal parts come into direct contact, without the protective oil film.

Causes of oil pump failure

Natural wear

The oil pump is a component that runs continuously and wears down over time. In high-mileage engines, the gears of the pump can wear, reducing pumping efficiency.

Contaminated or degraded oil

Old oil, contaminated with metal particles or dirt can damage pump components. Therefore it’s essential to follow the manufacturer’s oil change intervals.

Clogged oil filter

A clogged filter creates high resistance in the circuit, forcing the pump to work under abnormal conditions and accelerating wear.

Sump (oil pan) issues

A cracked or deformed sump can affect pump suction, leading to pressure losses.

What to do in case of failure

Immediate measures

- Stop the engine immediately when you notice signs of an oil pump failure

- Do not restart the engine until the issue is resolved

- Seek technical assistance to tow the vehicle

- Do not attempt to drive even short distances

Diagnosing the problem

A qualified mechanic will perform:

- Checking oil pressure with a specialized gauge

- Visual inspection of the oil pump and oil circuit

- Checking the condition of the oil and filter

- Diagnosing with specialized equipment

Repair or replacement

Depending on the extent of the fault:

- Repair – possible only for minor issues

- Complete replacement – necessary in most cases

- Checking for collateral damages – important to evaluate potential engine damage

Preventing oil pump problems

Preventive maintenance

- Follow the manufacturer’s recommended oil change intervals – essential to keep the pump in good condition

- Use quality oil that meets the manufacturer specifications

- Replace the oil filter at every oil change

- Periodically check the oil level and top up if needed

Early warning signals

- Lower-than-usual engine oil pressure on startup

- Subtle changes in engine noises

- Unexplained drops in oil level

- Oil that looks metallic or is contaminated

The oil pump is a critical engine component, and failure can have devastating consequences. Early recognition of symptoms and prompt action can save the engine from costly damage. Never ignore the oil warning light and follow a preventive maintenance schedule to avoid such problems.