- Connects front suspension to chassis and dampens road vibrations

- Consists of inner metal sleeve, rubber bushing, outer metal sleeve, with grease

- Symptoms include reduced ride comfort, direct cabin impacts, noises, and stiffness

- Worn bushings cause braking instability and front-end movement

The suspension system of a car is as critical as the engine for optimal vehicle operation. While the engine converts fuel into power, the suspension ensures stability, comfort, and safety during travel. One of the essential components of this system is the control arm bushing, a small but vital part that plays a crucial role in the car’s dynamic behavior.

The control arm bushing connects the front suspension to the vehicle’s chassis and absorbs vibrations generated by road irregularities. Although it may seem like a minor component, wear on this part can significantly compromise driving safety and comfort.

What is the control arm and its role

The control arm is mounted at the front of the suspension, where the front wheels rotate during steering. On trucks and rear-wheel drive vehicles, this component can also be present at the rear. The control arm system usually comprises two main elements:

- Upper control arm - positioned at the top of the suspension assembly

- Lower control arm - mounted at the bottom, often more robustly built

Each arm is equipped with rubber bushings at the ends, whose fundamental role is to allow controlled movement between the metal components without direct contact. These bushings act as a damping system for minor vibrations, being more effective than springs in this specific function due to their strategic positioning.

This configuration allows independent movement of the ends, essential for proper suspension operation. For this reason, the bushing and the control arm are subjected to considerable mechanical stress during cornering and when traversing obstacles.

Technical operation of the control arm bushing

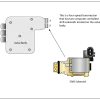

Bushing contains a specified amount of lubricant (grease) that reduces friction between metal components. Its construction includes:

Structural components

- Inner metal sleeve - connects via a central bar to the car’s frame

- Rubber bushing - central element that absorbs vibrations and allows controlled movement

- Outer metal sleeve - attaches to the wheels at both ends

This configuration allows independent movement of the ends, essential for proper suspension operation. Because of this, the bushing and the control arm are subjected to considerable mechanical stress during cornering and when crossing obstacles.

Wear symptoms of the control arm

1. Reduced ride comfort

When the control arm bushing does not function optimally, its ability to damp vibrations in the car diminishes significantly. On roads with irregularities or potholes, you will notice:

- Direct transmission of impacts into the cabin

- Unpleasant noises when driving over obstacles

- A feeling of stiffness in the suspension

2. Compromised braking system

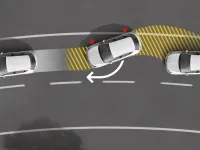

Although the bushing is not directly part of the braking system, its wear affects the vehicle’s stability during braking:

- The car becomes unstable during braking

- The front end may continue to yaw during stopping

- Additional vibrations that can affect other components

- Risk of complete bushing detachment in extreme cases

3. Tremors at the steering wheel

When the bushing is highly worn, lubrication between the metal sleeves becomes insufficient, resulting in:

- Vibrations transmitted directly through the steering system

- Increased shaking during braking

- Instability during cornering

4. Uneven wear of front tires

One of the most visible signs of problems with the bushing is uneven wear on the tires:

- One tire wears significantly more than the other

- Road contact becomes uneven

- Changes in wheel geometry

5. Vibrations in the steering wheel

Defective bushings manifest as perceptible vibrations in the steering wheel, especially:

- During braking

- When turning the car

- On roads with irregularities

Costs and replacement process

Costs for replacing the control arm and its bushing vary significantly depending on:

- Make and model of the vehicle

- Quality of replacement parts

- Complexity of the work

- Service rate

Factors influencing price

Premium cars and those with complex suspension systems (multilink, adaptive) incur substantially higher costs. Also, accessibility of components in the engine bay can affect the required labor time.

Recommendations for replacement

It is essential to use a specialized service for this repair because:

- It requires specific tools and technical expertise

- It involves wheel alignment after installation

- It can affect safety if not performed correctly

- It guarantees the quality of the work and components

Importance of preventive maintenance

Control arms and their bushings have a limited lifespan and wear naturally. Preventive maintenance includes:

Regular inspections

- Visual check of bushings for cracks or deformations

- Testing play in the suspension system

- Monitoring tire wear

Timely replacement

Delaying replacement can cause:

- Accelerated wear of other suspension components

- Deterioration of the steering system

- Exponentially higher repair costs

- Compromised road safety

Relation to other suspension components

The control arm bushing works closely with the camshaft in coordinating movements and with the entire suspension system to ensure vehicle stability.

A malfunction in this component can trigger a chain reaction affecting:

- Shock absorbers and springs

- Steering system

- Wheel bearings

- Suspension geometry

Understanding the role of the control arm bushing and early recognition of wear signs are essential for maintaining the vehicle’s safety and comfort. Investing in timely replacement of these components is always cheaper than the cost of extensive repairs caused by neglect.