- P0880 means fault in traction control module communication with PCM

- Symptoms include traction control failure, instability on slippery surfaces, and possible limp mode

- Common causes: faulty ON/OFF traction switch, damaged wiring, shorts, corroded connectors, blown fuses

- CAN bus issues can disrupt communication and trigger P0880

In modern vehicles equipped with electronic traction control, the P0880 error code points to a fault in the communication circuit between the traction control module and the Powertrain Control Module (PCM). This kind of fault can seriously affect performance and safety, making accurate diagnosis essential for proper repair.

Understanding this code is crucial for any owner of a modern car, given the complexity of electronic systems in today’s vehicles and the importance of traction control for road safety.

What P0880 Means

PCM has detected a fault in the traction control module communication circuit. The traction control module’s communication circuit provides crucial data to the PCM, which uses it to calculate engine RPM, fuel delivery strategy, and engine timing.

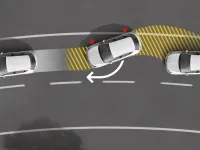

It’s important to note that this code specifically concerns vehicles equipped with an electronic traction control system. The traction control system works in close collaboration with other vehicle systems to ensure optimal grip and stability while driving.

When the P0880 Code Triggers

If the PCM does not receive an input signal from the traction control module communication circuit, an error code will be stored in the system memory. Simultaneously, a fault indicator light will illuminate on the vehicle’s dashboard to alert the driver to the problem.

A critical aspect is that the transmission may be placed into “limp mode” by the PCM as a protective measure. Limp mode allows the vehicle to operate with reduced functionality to prevent further damage to the systems.

Symptoms of the P0880 Code

Symptoms of this fault can vary in intensity, with the most common manifestations including:

- Traction control not operating properly – the system may not respond correctly or at all

- Loss of traction on slippery roads – the vehicle can become unstable on surfaces with reduced grip

- Inability to change gears – the transmission may remain locked in a gear

- Reduced fuel efficiency – fuel consumption can rise significantly

- Service light permanently on the dashboard

- A stored error code in the PCM memory

These symptoms may appear individually or in combination, and their severity can vary depending on the fault’s extent and driving conditions.

Common Causes of the P0880 Code

Faulty ON/OFF traction switch is by far the most frequent cause of this code being stored. This switch can wear over time or be affected by corrosion, preventing correct communication between the driver input and the system.

Other commonly identified causes include:

- Damaged wiring harness – electrical connections may be physically damaged

- Short circuits – can occur due to wear or insulation deterioration

- Corroded connectors – moisture and road salt can affect electrical connections

- Blown fuses – can interrupt power to the system

- CAN bus issues – the communication network may be compromised

Common Misdiagnoses

One of the most costly diagnostic errors is replacing the traction control module when the primary issue lies in damaged, shorted, or corroded wiring, or a faulty switch.

This confusion can cost hundreds or even thousands of euros in unnecessary repairs, which is why accurate diagnostics are essential.

Detailed Diagnosis of P0880

Understanding the CAN System

CAN stands for Controller Area Network. CAN is a complex communication system that allows multiple microcontrollers to communicate with each other without a host computer.

The CAN network is, in fact, a complex system of wires and connectors used as an information conduit, shared among two or more control modules. These modules effectively control every electric function of the vehicle, with the PCM acting as the primary controller.

How Control Modules Work

Control modules receive input data from various sensors and emit output signals to the system components and other control modules. For example:

- The PCM receives a signal from the vehicle speed sensor

- This signal is systematically transmitted to the affected control modules

- The cruise control module uses data for speed control

- The traction control system uses data to adjust its control strategy

- The ABS control module compares vehicle speed with data from the PCM

Diagnostic Process

Tools Needed

Several tools will assist in successfully diagnosing this code:

- A suitable scan tool for reading codes and real-time parameters

- A digital volt/ohm meter for testing electrical circuits

- A vehicle-specific electrical diagram

- A memory saver device to protect module programming

Initial Diagnostic Steps

Visual inspection should be the first step in any diagnosis. Carefully inspect all system wiring and connectors for:

- Visible physical damage

- Signs of corrosion

- Loose connections

- Damaged insulation

Repair or replace damaged wiring, connectors, and components as needed, ensuring they are disconnected, shorted, or corroded as appropriate. Always retest the system after repairs to ensure success.

Scanning and Recording Codes

If all wiring, connectors, and components (including fuses) appear normal, connect the scanner to the diagnostic port and record all stored codes.

This information can be extremely useful in diagnosing intermittent conditions that may have contributed to the code being stored. After clearing the codes, start and drive the vehicle to see if the code reappears. If the code does not return immediately, you may have an intermittent condition.

Diagnostic Challenges

Intermittent Conditions

Intermittent conditions can prove challenging to diagnose and, in extreme cases, can worsen the situation before a correct diagnosis is made. These problems may appear and disappear depending on ambient temperature, vehicle vibrations, or other external factors.

Recommendation for Professional Service

Unlike other fault codes, this type is best left to a professional, simply due to the large number of circuits involved.

An experienced technician with a specialized scanner (Autohex or Tech II) can often determine the general fault area much faster and more easily than someone using a simple code reader and a volt/ohm meter.

Risks of DIY Diagnosis

Disconnecting and testing each CAN bus pin requires considerable time and can be costly. Additionally, a memory-saver device must be installed to prevent PCM and other controllers from losing memory and requiring reprogramming.

Diagnosing this code with a digital volt/ohm meter would involve testing thousands of circuits individually. A misdiagnosis could damage expensive control modules and necessitate total vehicle reprogramming.

Detailed Procedure for Advanced Diagnostics

Manual Testing (for Experienced Technicians)

In the best-case scenario, you can attempt a continuity test after all control modules are disconnected, which could take about 40 hours or more, depending on the car model.

Some models are equipped with up to 18 separate modules, making the process extremely complex and time-consuming.

Steps for Manual Testing

If you choose to undertake this particularly challenging task, start with:

- Comprehensive visual inspection of all system circuits, connectors, and fuses

- Testing the control module ground circuits to ensure continuity with the battery

- Identifying defective wiring—this fault type is often caused by wiring damage

- Checking corroded electrical connectors that can raise circuit resistance

Using Electrical Schematics

Obtain a CAN system connection diagram and a values diagram, then use a digital volt/ohm meter to test continuity between the module’s individual connectors.

Compare your results with the manufacturer’s reference values and repair any broken or shorted circuits as needed.

Important Observations for Repairs

Replacing defective wiring is far more difficult than removing it from the vehicle’s complex wiring network. Therefore, precise identification of the faulty area is crucial before starting any repair.

Non-professional repairs can lead to far more severe and costly problems, including the need for full vehicle reprogramming or replacement of damaged control modules.

Conclusion

The P0880 fault code represents a complex issue that requires a systematic approach and, ideally, the expertise of a specialized technician. While some basic checks can be performed by the vehicle owner, the CAN system’s complexity and the risks associated with a misdiagnosis make professional intervention advisable in most cases.