- The camshaft position sensor helps the ECU time spark and fuel injection.

- Symptoms include startup trouble, idle misfires, power loss, and rev limit near 2000 RPM.

- Dashboard light may stay on; frequent misfires can cause damage; stop and service.

- Sensor is located near the camshaft on the engine’s outer side.

An engine runs correctly only when all of its components work in perfect synchronization. One of the crucial elements for this coordination is the camshaft position sensor, also known as the ignition impulse sensor. This seemingly small part can cause major engine problems when it fails, from misfires to the inability to start the vehicle.

Understanding how this sensor works and recognizing the symptoms of a fault can help you avoid costly repairs and keep the engine in optimal running condition.

What role does the camshaft position sensor play in the engine system

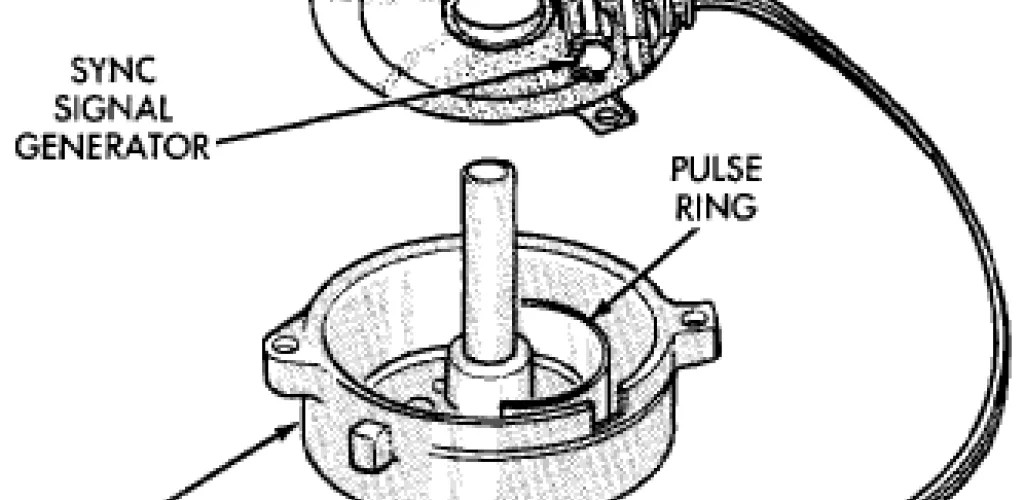

The ignition impulse sensor or camshaft position sensor is a vital component that allows the ECU to determine the exact position of the camshaft. This information is fundamental for the precise calculation of the spark timing and the moment of fuel injection into the engine cylinders.

The sensor’s operation is based on scanning a gear wheel perfectly synchronized with the camshaft. Through this continuous monitoring, the ECU can coordinate:

- Fuel injection sequence

- Selective cylinder control

- Crankshaft synchronization

- Intake and exhaust valve management

When the camshaft is no longer synchronized with the crankshaft, the intake and exhaust timings become completely imbalanced. The result is improper valve operation — the intake or exhaust valves may remain open during combustion or close when fuel intake should occur.

Symptoms of a defective camshaft position sensor

Recalling early signs of a fault can prevent more severe engine damage. Here are the main symptoms indicating a problem:

Startup and running symptoms

- Difficulty starting the engine or the engine won’t start

- Engine misfires, especially at idle

- Rev limit around 2000 RPM

- Loss of power during acceleration

- Uneven engine operation

Dashboard indicators

- The check engine light stays on persistently

- Possible interruptions in the connection to the onboard ECU

- Specific error codes stored in the ECU memory

Is it safe to drive with a faulty camshaft position sensor?

The answer largely depends on the severity of the fault and the symptoms shown. If the engine runs almost normally — revs correctly, accelerates as before, and shows no significant misfires — you can drive cautiously to a service.

Important: If the engine starts to misfire frequently, stop the vehicle immediately. Continuing to drive in these conditions can damage expensive components such as:

- Catalytic converter

- Lambda sensors

- Injectors

- Piston rings

Locating the camshaft position sensor

The sensor is located in the immediate vicinity of the camshaft, usually mounted on the outer side of the engine, opposite the timing gear. The exact position varies by make and model, but by following these steps you will identify it:

- Locate the camshaft position sensor in your engine

- Look for a cylindrical sensor with 2-3 wires connected

- Check the vehicle’s technical manual for the exact position

- Trace the wiring from the ECU toward the engine area

Procedure for cleaning the camshaft position sensor

In many cases, the issue isn’t a complete sensor failure but the accumulation of contaminants that affects reading accuracy. Here’s how you can clean the sensor:

Preparation for removal

- Disconnect the battery – Always start by disconnecting the negative terminal from the battery for safety

- Locate the sensor using the above instructions or the vehicle manual

- Take photos of the connections to reconnect correctly

Removal and cleaning

- Note the wire positions – The sensor has 2-3 wires; mark each position

- Disconnect the electrical connector carefully to avoid damaging the pins

- Remove the sensor with a suitable wrench or screwdriver

- Clean the sensor with electronic contact spray and a clean cloth

- Check the condition – Look for cracks, corrosion, or visible damage

Reassembly

- Mount the sensor back in the original position with the recommended tightening torque

- Reconnect the wires according to the notes made

- Reconnect the battery and start the engine to verify

When is sensor replacement necessary?

If after cleaning the symptoms persist and the check-engine light remains on, the sensor likely needs replacement. Other indications that suggest replacement:

- Visible cracks on the sensor body

- Advanced corrosion on terminals

- Electrical resistance outside normal parameters

- Age of the sensor (over 100,000 km)

Important note: If the vehicle continues to show symptoms after cleaning or replacement, consult a specialized mechanic for a full diagnostic. The issue could be related to timing synchronization or other components of the engine management system.