- DPF reduces diesel particulates and became mandatory after Euro 5/6 standards.

- It traps up to 0.01 μm particles with 95-100% efficiency; regen placement affects temperature.

- Two main types: dry high-temp regen and additive AdBlue/Eolys.

- Lifespan 100k-250k km, up to 350k with proper maintenance.

Diesel Particulate Filter (DPF) is one of the essential components of modern exhaust aftertreatment systems, and it is mandatory on all diesel vehicles manufactured after 2009. This technology was introduced to meet Euro 5 and Euro 6 pollution standards, significantly reducing emissions of harmful particulates into the atmosphere.

Although effective at reducing pollution, the particulate filter can cause problems if not properly maintained, especially on vehicles used predominantly in urban traffic. Understanding how it works and its maintenance requirements can prevent costly repairs and preserve engine performance.

What the particulate filter is and how it works

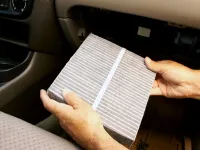

The particulate filter is a filtering device located in the exhaust system, downstream of the combustion process, designed to trap particles emitted by the engine with sizes up to 0.01 μm. It can be placed before or after the catalytic converter, or even between two catalysts.

Placing the filter before the catalytic converter favors reaching the temperature required for regeneration. Its efficiency ranges from 95-100%, significantly reducing unburned particle and ash emissions in the exhaust gases. These particles are directly harmful to human health, easily inhaled, remaining suspended and depositing on the walls of the lungs, with carcinogenic potential.

Types of particulate filters

In terms of construction and technology, there are two main types:

- Dry filters: require high temperatures for natural regeneration

- Additive-based filters: use AdBlue or Eolys for assisted regeneration

Evolution of DPF technology

The first vehicles equipped with DPF appeared with Euro 4 pollution standards, and starting with Euro 5 (2009 in the European Union), the particulate filter became mandatory for all diesel engines.

As part of Euro 6 regulations, for vehicles that do not meet the imposed limits and weigh more than 1,700 kg, in addition to the DPF there is also a mandatory AdBlue catalyst (SCR system).

Although initially developed only for diesel engines, in recent years direct-injection gasoline engines have also adopted filters (GPF - Gasoline Particulate Filter), but they are less common due to lower soot emissions.

Lifespan and influencing factors

The lifespan of a particulate filter ranges from 100,000 to 250,000 km, rarely exceeding 350,000 km under optimal operating conditions. This durability depends on several critical factors:

Factors affecting DPF durability

- Driving style: short trips and urban operation are detrimental

- Fuel quality: lower-quality diesel accelerates clogging

- Oil condition: degraded oil contributes to deposits in the filter

- Injector operation: defective injectors can cause incomplete combustion

- Air intake issues: affect the air-fuel mixture quality

- Condition of the EGR valve: a clogged EGR valve influences system pressures

- Turbocharger wear: can burn oil and contaminate the filter

Why the particulate filter gets clogged

For a car equipped with a diesel engine and DPF, ideal operation involves predominantly highway use, where the engine reaches optimal operating temperature. Diesel engines warm up more slowly than petrol engines, so urban driving at low speeds and RPM promotes filter clogging.

In urban operation, exhaust gas temperatures do not reach the values required for natural regeneration (600-700°C), and particles gradually accumulate in the porous structure of the filter.

DPF regeneration

Preventive regeneration

For vehicles used predominantly in urban areas, it is recommended to undertake a long drive every 2-4 weeks:

- Distance: 80-100 km outside the city

- RPM: above 2,500 rpm

- Cruising speed: around 60 km/h

- Duration: until the regeneration indicator disappears

Types of regenerations

Passive regeneration occurs automatically during long extra-urban trips, when the exhaust gas temperature reaches 600-700°C. This process goes unnoticed by the driver and represents the ideal operation.

Active regeneration is triggered by the ECU based on data from temperature and pressure sensors. The ECU regulates the amount of fuel to create a rich mixture, raising the temperature to 700-1000°C to burn off the deposits. The process lasts 10-20 minutes.

Forced regeneration is applied when automatic regenerations fail to clean the filter. It is performed with specialized diagnostic equipment and carries risks of overheating if procedures are not followed.

Chemical cleaning – a viable alternative

Chemical cleaning represents an effective and affordable solution for DPF maintenance. The principle is similar to that used by new vehicles equipped with AdBlue – using specialized chemical substances to dissolve deposits.

Recommended cleaning products

Products such as Liqui Moly 5171 DPF Cleaner contain special compounds developed for cleaning particulate filters. Most market products have a similar composition, differing only by brand and name.

Advantages of chemical cleaning

- Completely dissolves soot and ash deposits

- Reduces fuel consumption

- Improves engine performance

- Extends the filter life

- Much lower cost than replacement

Symptoms of a clogged particulate filter

Early warning signals

The first symptom is the yellow warning light on the dashboard, with the DPF symbol. If this warning is ignored, the following appear:

- Flashing regeneration light

- Audible warnings

- Onboard system error messages

Serious consequences of neglect

If regeneration is absent, the filter becomes irreversibly blocked, and the vehicle enters limp mode:

- Power and torque drop dramatically

- RPM is limited to a maximum of 3,000 rpm

- Fuel consumption increases

- Emissions of soot rise

- The vehicle may stall and fail to restart

Replacing the particulate filter

Replacement costs

Replacing with a new filter involves costs between €1,000-€4,000, depending on the model and manufacturer. The high price is due to the complex construction – a honeycomb-like structure with porous ceramic walls.

Professional cleaning process

As an alternative to replacement, professional cleaning involves:

- Removing the filter from the vehicle

- Measuring initial parameters

- Introducing the specialized chemical fluid

- Cleaning in a specially equipped space

- Final testing and a comparative report

DPF deletion – risks and consequences

Although some workshops offer DPF deletion for €200-€300, this practice is illegal and carries:

- Loss of vehicle warranty

- Risk of fines at RAR inspections

- Non-compliance with ITP standards

- Much higher emissions of harmful particulates

- Negative impact on the environment

DPF dashboard warning lights

Depending on the manufacturer, the warning light may vary, but common symbols include:

- DPF with droplets (the most common)

- Text