- P0606 signals PCM processor failure affecting many systems over CAN Bus, making diagnosis hard

- CAN Bus modules include TCM, ABS, instrument cluster, fuel, turbo, anti-theft, cruise, traction

- Fault may require up to eight cycles before the service light stays on

- Symptoms include engine stalling, hard starting, irregular idle, transmission issues, high fuel use

The P0606 fault code represents one of the most complex diagnostic challenges a car owner can face. This error is related to a PCM (Powertrain Control Module) processor failure, which can significantly affect the vehicle’s overall operation.

Unlike other OBD2 codes that refer to sensors or specific components, P0606 points to a fundamental problem in the car’s electronic brain, potentially impacting multiple systems at once.

What the P0606 fault code means

This code indicates that an error in the PCM processor has been detected, either by the PCM itself or by other control modules on the vehicle’s network. The modules involved in this communication may include:

- Transmission Control Module (TCM)

- ABS control module

- Instrument panel control module

- Fuel injection control module

- Turbo control module

- Anti-theft control module

- Cruise control module

- Traction control module

- Climate control module

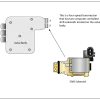

These modules communicate via the CAN Bus network (Controller Area Network), a complex system that enables information exchange between the vehicle’s various electronic components.

How the code is activated and stored

In the case of a PCM processor error, the system will automatically store the fault code and illuminate the service light on the dashboard. It is important to know that some vehicle models require multiple consecutive error cycles (up to 8) before the service light comes on permanently.

This “confirmation” feature helps avoid false alarms caused by temporary electromagnetic interference or voltage fluctuations.

Symptoms of the P0606 fault code

The manifestations of this problem can be diverse and seemingly unrelated, which makes diagnosis challenging for those without technical experience:

Engine performance issues

- The engine may stall at idle or run at below idle speed

- Hard starting or impossible starting

- Idle speed fluctuations

- Loss of power while driving

Transmission and handling issues

- Gear shifts that are difficult to engage (automatic transmissions)

- Gears that do not engage properly

- Unpredictable transmission behavior

Other symptoms

- Increased fuel consumption

- Intermittent operation of auxiliary systems

- Illumination of the service light

- Storage of secondary error codes

Main causes of the P0606 code

Unlike most PCM codes, which are caused by failures of external components, P0606 is usually the result of an internal electrical problem or communication issue:

Wiring and connection problems

- Faulty electrical connections: Corroded or loose connectors can interrupt communication

- Damaged wiring: Broken, corroded, or shorted CAN Bus wires

- Ground problems: Faulty ground connections of the control modules

Hardware faults

- Defective PCM driver: Internal PCM circuits may be damaged

- Power supply issues: Voltage fluctuations or problems with the main relay

- Electromagnetic interference: Caused by faulty components or aftermarket installations

Software issues

- Memory corruption: Data stored in the PCM may be compromised

- Communication conflicts: Between modules with incompatible software versions

Common incorrect diagnosis

One of the biggest challenges in diagnosing P0606 is the tendency to treat symptoms instead of addressing the root cause. Less experienced technicians may commit the following mistakes:

- Replacing secondary components: Repairing injectors, exhaust system, or other components that display error codes as a result of the communication fault

- Ignoring the order of codes: Codes should be diagnosed in the order they are stored, with priority given to communication codes

- Premature PCM replacement: Without full testing of external circuits

Professional diagnosis of the P0606 code

Understanding the CAN Bus system

CAN (Controller Area Network) is the backbone of modern electronic communication in a car. This system allows multiple microcontrollers to communicate efficiently without the need for a central host computer.

The CAN network works as a shared information highway among two or more control modules. For example, when the PCM receives a signal from the vehicle speed sensor, this data are transmitted simultaneously to:

- Cruise control module (for speed control)

- Traction control system (for control strategy)

- ABS module (for wheel speed comparison)

Tools needed for diagnosis

Essential tools:

- Professional OBD2 scanner (Autohex, Tech II or equivalent)

- Digital multimeter with CAN network testing functions

- Oscilloscope (for CAN signal analysis)

- Memory saver devices

Optional tools:

- CAN Bus protocol analyzer

- Vehicle-specific diagnostic software

Step-by-step diagnostic procedure

Step 1: Visual inspection

Always start with a careful inspection of:

- All visible cables and connectors

- System fuses

- Ground connections of the control modules

- Battery and charging system

Step 2: Initial scan

- Connect the scanner to the diagnostic port

- Record all codes stored in the order they appear

- Note the freeze-frame data associated with P0606

- Check communication with all connected modules

Step 3: System testing

- Clear the codes and perform a test drive

- Monitor for code reappearance

- Test operation under different conditions (idle, acceleration, braking)

Step 4: Advanced diagnostics

If the code persists, specialized tests are required:

- CAN Bus continuity testing: Checking the physical integrity of the network

- Signal analysis: Using an oscilloscope to verify CAN waveform

- Resistance testing: Checking termination resistance of the network (120 ohms)

- Testing individual modules: Isolating and testing each connected module

Specific repairs for the P0606 code

Simple repairs

- Cleaning connectors: Using electrical contact cleaner

- Replacing fuses: Checking and replacing faulty fuses

- Repairing wiring: Soldering or replacing damaged wires

Complex repairs

- Replacing defective modules: After accurately identifying the defective component

- PCM reprogramming: In case of software corruption

- Harness replacement: For extensive wiring problems

Costs and repair time

- Professional diagnosis: 2-8 hours (depending on complexity)

- Simple repairs: 1-3 hours

- PCM replacement: 3-6 hours (including reprogramming)

- Cost of parts: From 50 RON (connectors) to 3000+ RON (new PCM)

Recommendations for vehicle owners

When to call a specialist

P0606 is one of the few situations where immediate specialist attention is recommended for the following reasons:

- System complexity: Involves multiple modules and circuits

- Risk of damage: Incorrect diagnosis can damage expensive modules

- Need for reprogramming: Many interventions require software and specialized equipment

- Time required: Manual diagnosis can take 40+ hours

Preventive measures

To avoid the appearance of this code in the future:

- Regular battery maintenance: A weak battery can cause voltage fluctuations

- Avoid unauthorized modifications: Aftermarket installations can interfere with CAN Bus

- Moisture protection: Exposed connectors can corrode and cause issues

- Software updates: Keep modules on recommended software versions

The P0606 fault code represents a significant technical challenge that requires specialized expertise for diagnosis and repair. While costs can be high, a professional approach will ensure proper repair and prevent damage to other costly vehicle components.