- Transmits engine power to the transmission and enables smooth gear changes.

- Key components include clutch disc, flywheel, pressure plate, and release bearing.

- Release bearing actuates the diaphragm to disengage the clutch.

- In rest, disc engages; pressing pedal disengages to allow gear shifts; replacements costly.

The clutch is one of the most important systems in a manual transmission vehicle, enabling controlled engagement and disengagement of the engine from the gearbox. While most drivers know the clutch pedal allows smooth starts from rest and gear changes, the complex mechanism behind this function often remains a mystery.

Understanding how the clutch works and its components is essential for any driver who wants to keep their vehicle in peak condition and avoid costly repairs. A clutch kit can cost hundreds or even thousands of euros, and replacement requires extensive disassembly.

The fundamental role of the clutch in the transmission system

Power transmission - The first function is to transmit the power flow from the engine to the transmission. This transmission must be efficient to avoid losing the power generated by the engine.

Engagement and disengagement - The second function, equally important, allows controlled engagement and disengagement of the engine from the gearbox. Without this capability, gear changes would be impossible, and starting from rest would occur with violent shudders.

Praktically, the clutch acts as an intelligent intermediary between the engine and the gearbox, protecting both components from shocks and enabling fine control over power transmission.

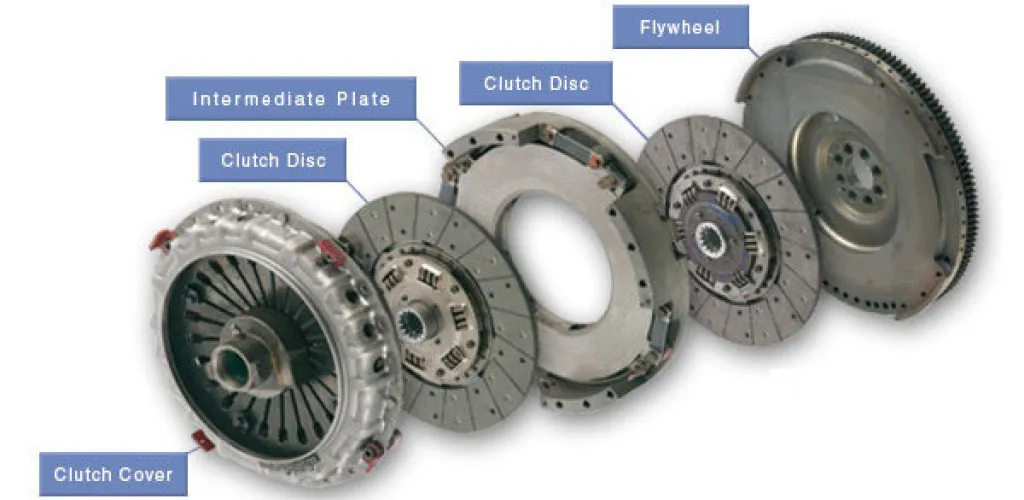

Components of a complete clutch kit

Clutch disc

The clutch disc is the central part of the system, made of steel and coated on both sides with friction material (metal, asbestos, or Ferodo). In the center of the disc are special springs that cushion contact with the flywheel, preventing vibrations and shocks.

Flywheel

The flywheel is connected directly to the engine crankshaft and serves as the contact surface for the clutch disc. It ensures a smooth transmission of rotational motion.

Pressure plate

Made from very strong steel, the pressure plate contains in the center flexible, mobile petals (the diaphragm) that can be actuated only by pressing the clutch pedal. The housing of the plate is fixed to the engine flywheel with bolts.

Release bearing

Designed to withstand high RPMs and large forces, the release bearing pushes the diaphragm of the pressure plate and is connected to the release fork by cable, hydraulic system, or directly from the pedal.

Principle of clutch operation

In the resting position (pedal not pressed)

When the clutch pedal is not pressed, the pressure plate suspenses the clutch disc against the flywheel, like a sandwich. This compression ensures direct transfer of power from the engine to the gearbox.

In the disengaged position (pedal pressed)

When we press the clutch pedal, the release bearing acts on the diaphragm of the pressure plate, releasing the clutch disc. At this moment, disengagement is achieved – the engine is disconnected from the gearbox, allowing gear changes.

The clutch acts as the first protection system in emergency situations. If you need to perform a sudden stop and there isn’t time to press the clutch, the clutch disc will slip on the pressure plate and flywheel, preventing damage to the crankshaft or gearbox.

Materials and advanced technologies in clutch construction

Standard clutches

Standard clutches use traditional friction materials such as ferodo, asbestos, or metallic compounds. They offer an optimal compromise between durability, comfort, and cost.

Kevlar-reinforced clutches

For modified vehicles or those subjected to higher loads, Kevlar-reinforced discs are used. This material offers:

- Superior high-temperature resistance

- Increased durability under stress

- Suitable for daily use, with only slightly more aggressive engagement

Ceramic-plate clutches

These represent the extreme solution for very high power levels:

- Exceptional resistance to very high power

- Almost instant engagement (no progression)

- Not suitable for daily use

- High risk of gearbox damage

Signs of a faulty clutch

Main symptoms of wear

Clutch slipping is the most common symptom. It manifests as:

- Difficult vehicle acceleration

- Strong smell of burnt clutch material

- Keeping engine revs high while the vehicle accelerates slowly

Noise and vibrations indicate problems with the release bearing:

- Specific noise when operating the pedal

- Vibrations transmitted through the pedal

- Difficulties in gear shifting

Difficult gear changes suggest that the entire kit is nearing the end of its life.

When to call a specialist

Due to the complexity of the operation (separating the gearbox from the engine), it is essential to contact an authorized service with experience and the necessary equipment for such interventions.

Strategies to extend clutch life

Correct operating technique

Complete disengagement

- Press the clutch pedal fully, through the entire travel

- Ensure the disc no longer touches the flywheel

- Avoid partial disengagement that prematurely wears components

Progressive engagement

- Lift off the clutch pedal gradually and smoothly

- Avoid sudden release that can damage the disc

- Achieve a smooth engagement, especially when leaving from a standstill

Common mistakes to avoid

At stoplights and crossings

- Do not keep your foot on the clutch pedal during long stops

- Shift to neutral and release the pedal to protect the release bearing

While driving

- Do not rest your left foot on the clutch pedal

- Avoid accidental partial disengagement

- Maintain a correct driving posture

Influence of driving style

The clutch kit life varies dramatically with driving style:

- Sport driving: 30,000–60,000 km

- Normal urban driving: 80,000–120,000 km

- Defensive driving: over 150,000 km

Special considerations for modified vehicles

After chiptuning (Stage 1)

Even a Stage 1 map increases clutch demand significantly, especially on diesel engines where torque can rise by 20–30%. In this case:

- Opt for a Kevlar reinforced disc

- Consider strengthening the pressure plate

- Carefully monitor signs of wear

For extreme modifications

At large power increases (over 50%), a ceramic clutch becomes necessary, but with compromises:

- Not suitable for daily comfortable use

- Increased risk of gearbox damage

- Requires a reinforced gearbox for high power

Recommendations for replacement and maintenance

Selecting a service

Replacing a clutch requires:

- An experienced service with specialized equipment

- Tools specific for safe disassembly

- Technical knowledge for proper reassembly

- Warranty for the performed work

Costs involved

Budget for:

- Clutch kit cost (200–1500 euros)

- Labor (300–800 euros)

- Possible additional parts (refaced flywheel, cylinders)

- Fluids and consumables

Preventing problems

- Regularly check the clutch hydraulic fluid level

- Observe changes in pedal feel

- Do not ignore early signs of wear

- Schedule regular inspections at the service

The clutch is a significant investment in the safety and performance of your vehicle. By understanding how it works and applying correct operating techniques, you can considerably extend its life and avoid the high costs of premature replacement.