- Recycling car parts protects environment and conserves resources while reducing costs

- Used oil is highly recyclable after refining; improper disposal contaminates groundwater

- Oil filters are up to 90% steel, fully recyclable after draining

- Windshields are laminated glass with PVB; recycling separates layers for reuse

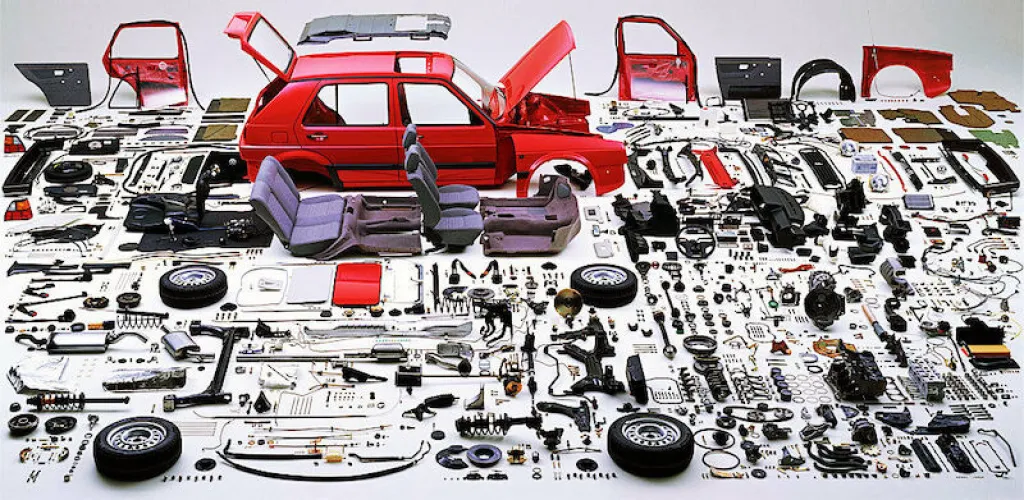

Recycling car parts is essential for protecting the environment and conserving natural resources. Most vehicle components are consumables that require periodic replacement, depending on their quality, driving style, and how the vehicle is maintained. Whether a part wears out over time or must be replaced after an accident, it is important to ensure that all vehicle components are in perfect working order.

Whenever you perform maintenance yourself, recycle worn parts instead of discarding them. Many auto components contain valuable materials that can be reused, but also toxic substances that can seriously pollute the environment if disposed of improperly. Recycling not only protects nature but also helps reduce the production costs of new parts and conserve natural resources.

Oil and Oil Filters

Motor oil is one of the most frequently replaced car fluids, needing changes every 5,000–10,000 km, depending on the oil type used and operating conditions. Unlike many other consumables, oil does not wear out in the classic sense — it loses lubricating properties as soot particles, microscopic wear debris from rubbing surfaces and additive degradation accumulate.

This characteristic makes used oil highly recyclable. Through advanced refining processes, used oil can be cleaned of impurities and converted into base oil for new lubricants or used as an energy source in various industrial applications. A single liter of used oil discarded improperly can contaminate up to one million liters of groundwater, which is why recycling is crucial.

Oil filters also present an excellent recycling opportunity. They contain up to 90% steel, a valuable and fully recyclable metal. Before recycling, the filter must be drained completely of oil, then the metal housing can be melted and reused in the production of new parts. Most authorized auto service centers collect used oil and filters free of charge, and are legally obliged to do so.

Glass and Windshields

Windshields have an average lifespan of about five years, though this interval can vary significantly depending on road conditions, usage frequency and exposure to extreme temperatures. Unlike ordinary glass, windshields are built from a laminated, multi-layer structure: an interlayer of PVB (polyvinyl butyral) bonded between two sheets of tempered glass.

This complex construction serves an essential safety purpose — in case of impact, the windshield shatters into thousands of tiny fragments that remain bonded to the plastic sheet, preventing injuries to occupants. However, this structure makes recycling more difficult than for ordinary glass.

Modern recycling technologies can efficiently separate the three layers, recovering both glass and PVB. Recovered glass can be transformed into glass fiber for insulation, used in the production of new glass, or even in abrasive materials. PVB can be reused in a variety of industrial applications, from carpets to packaging materials.

Rear windscreen and side windows are made of safety glass (tempered), which breaks into small pieces with dull edges. They are easier to recycle than windshields, with a process similar to ordinary glass.

Tires

Tires represent one of the most pressing environmental issues in the auto industry. Globally, hundreds of millions of used tires are generated annually, and improper disposal creates major problems. Tires are composed of synthetic and natural rubber, steel, textile fibers and various chemicals giving them strength and durability.

The main issue is that tires are practically non-biodegradable — they can persist in the environment for centuries. Moreover, attempts to dispose of them by burning are extremely dangerous and illegal, releasing toxic substances such as dioxins, furans and polycyclic aromatic hydrocarbons into the atmosphere, which are carcinogenic.

Fortunately, tire recycling technologies have evolved significantly. The recycling process starts with cutting and shredding tires into smaller pieces, followed by separation of metal components using magnetic separators. The shredded rubber can then be transformed into:

- Rubber granules used for synthetic turf on sports fields, providing impact absorption

- Rubber-modified asphalt which provides a quieter and more durable road surface

- Industrial mats and anti-slip surfaces

- Automotive industry components such as protective sills or sound insulation

- Alternative fuel in industrial furnaces, tires having a high calorific value

In Romania, there is a growing network of used tire collection points. Many tire retailers offer free take-back services when purchasing new tires, and some even offer discounts to encourage recycling.

Engine Components

The engine is the heart of any car and contains hundreds of complex components that can be reconditioned or recycled. The engine block, cylinder head, crankshaft, camshaft, pistons, connecting rods and many other parts are made from aluminum, steel or other valuable alloys that can be recovered.

Reconditioning entire engines or individual components is a flourishing industry. A worn-out engine can be dismantled, cleaned and reconditioned by:

- Cylinder resurfacing to remove wear and restore original dimensions

- Replacement of crankshaft and camshaft bearings

- Valve seating and replacement of worn guides

- Dynamic balancing of moving assemblies

- Replacement of gaskets and rings

This process can bring an engine to specifications nearly identical to a new one, at a fraction of the cost. Reconditioned engines are particularly sought after for older vehicles or auto restorations.

Even when an engine can no longer be reconditioned due to severe damage, its metal components remain highly valuable. Aluminum from the engine block and head can be melted and reused with the same properties as primary aluminum. Steel from the crankshaft, rods and other components can also be remelted and used in various industrial applications.

Metal Components

Metals may be the most valuable and easiest-to-recycle category of materials in a car. An average vehicle contains about 65-70% metal in its total makeup, including steel, aluminum, copper, zinc and other alloys.

- Steel forms the structure of the body, chassis and many mechanical components. This metal can be recycled indefinitely without losing properties, and the recycling process uses about 75% less energy than producing steel from ore. Steel components include:

- Body and exterior panels

- Frame and chassis

- Suspension and braking systems

- Exhaust system components

- Springs and elastic components

- Aluminum is found increasingly in modern vehicles because of its excellent strength-to-weight ratio. Alloy wheels, engine blocks, valve covers, radiators and various decorative components can all be recycled. Aluminum recycling saves up to 95% of the energy required to produce primary aluminum and can be reused countless times.

- Copper is present in wiring, radiators, alternators and various electrical components. It is a highly valuable and fully recyclable metal, which is why end-of-life vehicles are often targets for wiring theft.

- Other metals such as zinc (used for galvanizing and corrosion protection), lead (in batteries and soundproofing materials) and precious metals from catalysts (platinum, palladium, rhodium) add further value to the recycling process.

Many people who own very old or damaged cars take them to dismantling or scrapping centers, where they can receive money based on the weight and type of recoverable metals. This process not only provides a financial benefit but ensures valuable metals are recovered and reinjected into the production chain.

Plastic Components

Although not immediately obvious, a modern car contains between 150–200 kg of plastics, representing about 10–15% of the vehicle’s total weight. These plastics range from polypropylene (PP) and polyethylene (PE) to ABS, polyurethane and various composite materials.

Plastics are used extensively in:

- Dashboards and center consoles, which alone can weigh 10–15 kg

- Door upholstery and interior decorative panels

- Bumpers, which on modern vehicles can weigh 5–8 kg each

- The radiator grille and various exterior styling components

- Under-hood components such as air filter housings, engine covers, fluid reservoirs

- Ventilation and air conditioning systems — air ducts and vents

- Acoustic and thermal insulation

Plastic recovery and recycling presents specific challenges because a single vehicle may contain up to 20 different types of plastic. Proper sorting is essential to obtain high-quality recycled materials. Fortunately, most auto manufacturers mark plastic components with identification codes to aid sorting.

The recycling process involves:

- Dismantling plastic components from the vehicle

- Sorting by plastic type

- Shredding into small granules

- Washing to remove impurities

- Melting and extrusion into new granules

Recycled plastics can be transformed into new parts for the auto industry or used in other industries—from furniture to construction materials. Modern automakers are using more and more recycled plastics in new vehicles; some premium brands use up to 30–40 kg of recycled plastics per vehicle.

Car Batteries and Electronic Components

Lead-acid car batteries are among the most toxic yet easiest to recycle car components. A typical car battery contains about 8–10 kg of lead, 3–4 liters of sulfuric acid and a plastic case. All of these components are highly valuable and fully recyclable.

Lead is an extremely toxic heavy metal, potentially causing serious neurological problems, kidney damage and other health issues. For this reason, almost all countries have implemented strict collection and recycling systems for car batteries. In the European Union, the recycling rate of car batteries exceeds 99%, making it one of the most successful recycling programs.

Battery recycling involves:

- Draining the acid which can be neutralized and transformed into sodium sulfate (used in detergents) or purified and reused

- Crushing the battery and separating the components

- Melting the lead which is then refined and can be used for manufacturing new batteries (80% of the lead in a new battery comes from recycling)

- Recycling the plastic case which can be transformed into new cases or other plastic products

Modern electronic components contain a wide range of valuable and toxic materials. Modules such as ECU (engine control unit), TCU (transmission control unit), airbags, sensors and other systems contain:

- Precious metals such as gold, silver and palladium in small but valuable quantities

- Copper from wiring and printed circuit boards

- Toxic substances such as mercury, cadmium and various flame retardants

Recovering these materials requires specialized dismantling and separation processes. Precious metals are recovered through chemical and electrochemical processes, while reusable components can be tested and resold as functional used parts.

Important considerations:

- Never throw a car battery in household trash

- Most battery retailers accept old batteries and offer a discount when purchasing a new one (buy-back/return system)

- Faulty electronic components can be taken to specialized WEEE (Waste Electrical and Electronic Equipment) collection centers

- Check with your mechanic whether they accept taking worn electronic components for recycling

Each of us plays a role in protecting the environment through proper recycling of car parts; every recycled component means less natural resource consumption, less energy use, and less pollution. Additionally, the recycling industry creates jobs and contributes to the circular economy, turning waste into valuable resources.