- Brake booster uses engine vacuum to amplify pedal force, reducing driver effort.

- Hard-to-press pedal or pedal sticking indicates booster failure; dangerous if severe.

- Booster failure increases stopping distance, especially in wet, icy conditions.

- Intermittent boost and pedal-area whistling indicate vacuum/diaphragm or check valve problems.

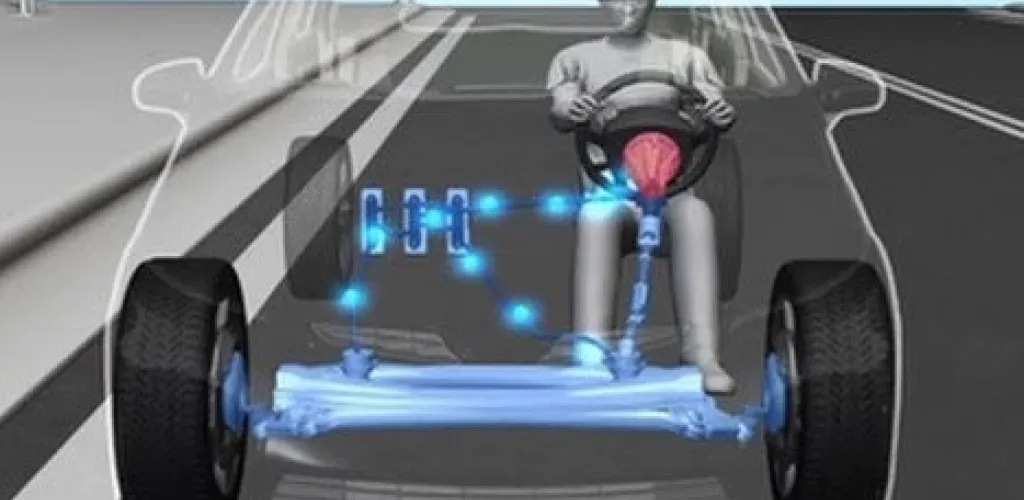

Brake booster, also known as a brake amplifier or brake booster, is an essential component that enables efficient braking with minimal effort from the driver. This system, present on most modern cars, uses the vacuum created by the engine to amplify the force applied to the brake pedal, turning a light press into a strong braking force.

Understanding how the brake booster works and recognizing signs of failure can prevent dangerous situations and costly repairs.

Role and operation of the brake booster

The brake booster is strategically positioned between the brake pedal and the master cylinder (central brake pump), with the role of reducing the effort required by the driver for effective braking. This system uses the pressure difference created by the engine vacuum to amplify the applied force.

Evolution of braking systems

In the past, cars were equipped with drum brakes that required considerable effort to actuate. Drivers who operated such vehicles became accustomed to pressing the brake pedal hard, a habit that persists even today, although modern cars with brake boosters require only a light press.

The shift to disc brakes, combined with the brake booster, revolutionized safety and comfort at the wheel, providing progressive and controllable braking.

Warning signs: symptoms of a faulty brake booster

Early recognition of problems with the brake booster can prevent dangerous situations and damage to the entire braking system.

Hard-to-press brake pedal

The most evident symptom of a faulty brake booster is a significant increase in the effort required to depress the brake pedal. In severe cases, the brake pedal may no longer return to its original position, staying on the floor.

Warning: This issue requires immediate intervention, as it can lead to a complete loss of braking capability and serious accidents.

Increased braking distance

When the braking system does not receive the necessary boost, the car will need a longer distance to stop. This problem becomes extremely dangerous in wet or icy conditions or in heavy traffic.

Factors that worsen this situation:

- Wet or icy road surface

- High speed

- Insufficient following distance

- Reduced visibility

Intermittent braking booster operation

A brake booster that stops operating intermittently is a serious problem, creating an unpredictable situation for the driver. This fault can cause:

- Sudden loss of braking assist

- Premature deterioration of braking system components

- Major risk of accident

Suspicious noises from the pedal area

A characteristic whistling sound coming from under the dash, especially during braking, typically indicates a problem with the brake booster vacuum. This sound occurs due to:

- Low vacuum pressure in the vacuum chamber

- Cracks in the brake booster diaphragm

- Issues with the check valve

Brake booster testing procedure

Before scheduling a visit to the service, you can perform a preliminary check to confirm the brake booster status.

Preparation for testing

Initial setup:

- Start the engine

- For manual transmission: shift to neutral

- For automatic transmission: selector in the “P” (Park) position

- Engage the parking brake for safety

First stage of testing

Procedure:

- Let the engine run for a few minutes

- Turn off the engine

- Press the brake pedal 4 times in succession

- On the fourth press, maintain a light, steady pressure

- Start the engine again

Expected result: The pedal should move slightly downward when the engine starts, indicating proper vacuum operation.

Second stage of testing

Procedure:

- With the engine off, turn the ignition on

- Press the brake pedal 4 times

- Observe the pedal behavior after the 2nd and 3rd presses

Interpreting the results:

- If the pedal rises after 2-3 presses = the brake booster maintains vacuum correctly

- If the pedal stays down = possible vacuum leak

Final verification stage

Leak test:

- Start the engine

- Press and hold the brake pedal

- Turn off the engine (with the pedal still pressed)

- Maintain the position for 30 seconds

Evaluation: The pedal should remain in position. If it rises, there is a vacuum leak in the system.

Professional diagnosis and repair

If the tests indicate issues with the brake booster, professional diagnosis is essential. Auto specialists use specialized equipment such as:

- Vacuum gauges to measure vacuum

- Vacuum pumps to test leak tightness

- Electronic diagnostics for modern systems

Repair costs

The cost of replacing or repairing the brake booster varies depending on:

- The vehicle make and model

- The type of brake booster (vacuum-assisted or electro-hydraulic)

- The need to replace related components

- The complexity of the intervention

Preventive measures and maintenance

To extend the life of the brake booster:

Regular checks:

- Check the brake fluid level monthly

- Periodically test braking efficiency

- Notice any changes in pedal feel

Timely replacement:

- Replace the air filter as scheduled

- Inspect vacuum hoses for cracks

- Replace brake fluid according to specifications

Conclusion

The brake booster is a vital component for road safety, and its proper operation should not be neglected. Recognizing failure signs and performing verification tests can prevent dangerous situations and high repair costs.

Remember that any braking system issue requires immediate intervention—your safety and that of other road users depends on the correct operation of this essential system.

Sourse photo: youtube.com, pinterest.com, esschwab.com, dnrcomponents.co.uk, blog.autointhebox.com