- Weak braking may indicate worn shoes, overheated drum, oil contamination, or incorrect adjustment

- Unusual braking noises indicate wear, metal-to-metal contact, dust, or drum deformation

- Brake pedal vibrations point to drum ovality, cracks, uneven wear, or misadjustment

Drum brake systems and brake shoes are established technology, still used on many vehicles, especially on the rear axle. While they are considered older than disc brakes, these components remain essential for road safety and require constant attention from drivers.

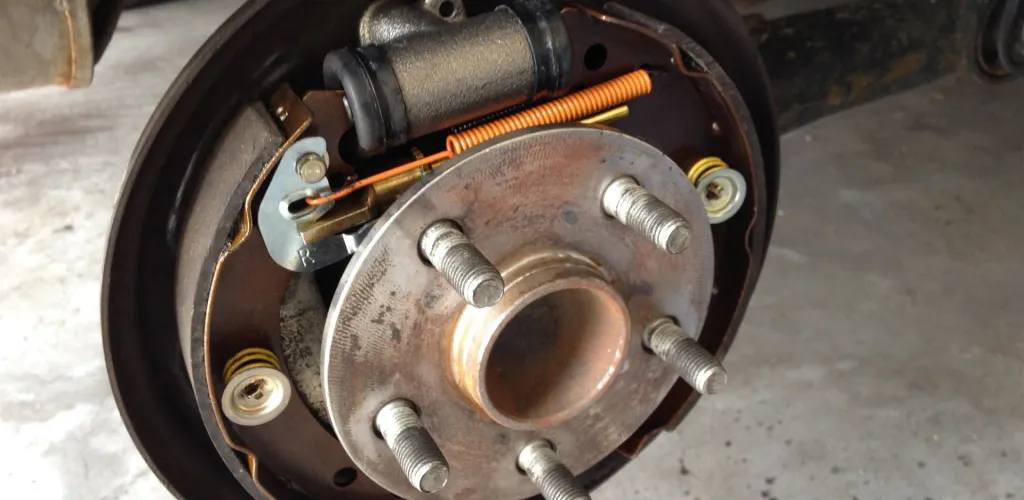

Drum brakes and brake shoes are integral components of the braking system, commonly found on older-generation vehicles, but also on many modern cars with rear drum setups. Functionally, the drum brake acts as the brake disc, while the brake shoes are the equivalent of brake pads in disc systems.

How the drum brake system works

The drum brake is shaped like a bowl and is attached to each wheel. When you press the brake pedal, the brake shoes are pushed toward the inner walls of the drum, creating the friction needed to slow down the vehicle. It is a concept similar to the disc brake system, with differences in the design and arrangement of the components.

This type of system has both advantages and drawbacks. Benefits include lower manufacturing cost and automatic self-adjustment of the distance between the shoes and the drum. Disadvantages include poorer heat dissipation and maintenance challenges.

Main symptoms of failures

1. Weak braking and reduced efficiency

If you press the brake pedal and it takes a long time for the car to slow down or stop, you may have a problem with the drum brake or the brake shoes. This symptom can indicate:

- Excessive wear of the friction material on the shoes

- Deformation of the drum due to overheating

- Presence of oil or grease on the friction surface

- Incorrect adjustment of the distance between the shoes and the drum

However, other components of the system could also be faulty, but the common cause generally revolves around these two main components.

2. Unusual noises during braking

In addition to weak braking performance, you may hear unusual noises when braking. This happens over time as drum brakes are not as effective as discs at absorbing and dissipating heat.

Types of noises may include:

- Metallic squeal: indicates complete wear of the friction material

- Sharp squeaking: sign of metal-to-metal contact

- Muffled noise: may indicate accumulated brake dust

- Popping: suggests drum deformation

Because of this problem, excessive heat can damage system components. When the brake shoes are pressed into the drum, you will hear unusual noises that should not be ignored.

3. Brake pedal vibrations

As mentioned, over time the drum brakes wear and may deform. When they become too worn or warped, you will start to feel vibrations in the brake pedal as you press it.

These vibrations can be caused by:

- Drum ovality: uneven wear that creates an irregular surface

- Cracks in the drum: damage affecting uniform contact

- Uneven wear of the shoes: creates varying contact points

- Incorrect adjustment: causes intermittent contact

It is not advisable to ignore this issue, since braking performance drops significantly. It is advisable to replace both the drums and the brake shoes to restore safety.

4. Weak or non-functional parking brake

The parking brake largely depends on the brake shoes, which must clamp firmly onto the drum to hold the vehicle in place. If there is a problem with the brake shoes and/or the drum, the parking brake will not function properly.

When you operate the parking brake, the vehicle may not stay stationary and could move on inclined surfaces, posing a major safety risk.

Other symptoms to monitor

Vehicle pulls during braking

If the car pulls to one side when braking, this can indicate:

- Uneven wear of the shoes between the left and right sides

- Seized wheel cylinder

- Oil contamination of a single drum

Soft brake pedal

A pedal that sinks too far or requires pressing to the floor can signal:

- Incorrect shoe adjustment

- Excessive wear of components

- Problems with the hydraulic system

Replacement and maintenance costs

Brake shoe costs

There are four brake shoes per vehicle, two per rear wheel. Each brake shoe costs around 100 RON, so replacing all shoes is about 400 RON, plus labor which ranges from 200-400 RON, depending on the complexity of the job and the service chosen.

Drum costs

There are two drums (for the rear wheels), one per wheel. When both drums need replacement, expect to pay roughly 1,000-1,500 RON for parts, plus labor that can reach 300-500 RON.

Factors influencing costs

- Vehicle make and model: premium cars have more expensive components

- Pawns quality: OEM parts are more expensive than aftermarket

- Work complexity: some vehicles require additional disassembly

- Drum condition: sometimes drums can be rebuilt rather than replaced

Recommendations for preventive maintenance

To avoid large repair costs and maintain safety:

- Periodically check the braking system at a specialized workshop

- Do not ignore unusual braking noises

- Regularly test the parking brake’s effectiveness on a gentle incline

- Avoid hard braking that speeds wear of components

- Replace components in sets for uniform operation

Remember: The braking system is the vehicle’s most important active safety system. Any suspect symptom should be promptly investigated by a qualified mechanic.

Photo sources: car-newmodels.net, insurancejournal.com, autoguru.com.au