- Modern brakes feature primary, secondary safety, and emergency systems for redundancy.

- Hydraulic issues include deteriorating brake hoses and corroded metal lines causing leaks.

- Mechanical failures involve caliper/wheel cylinder leaks, soft pedals, and uneven pad wear.

- Master cylinder faults cause floor pedal, air ingress, and reduced braking efficiency.

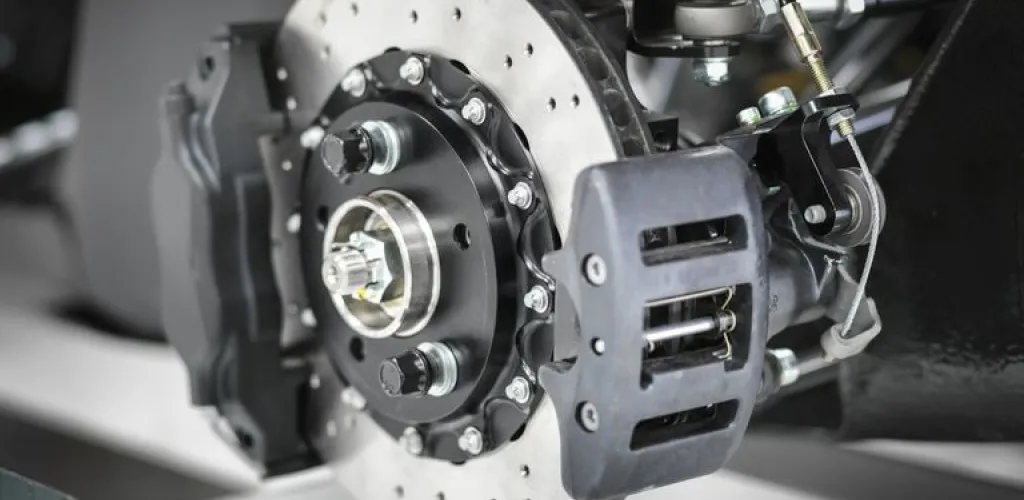

The braking system is one of the most critical safety components, responsible for bringing the car to a controlled stop in any situation. While many drivers view it as a simple mechanism—a pedal connected to a few pads pressing on discs—the reality is far more complex. The braking system, modern, includes multiple interconnected components, backup systems, and advanced assistive technologies.

The importance of this system is underscored by automakers implementing not one, but three distinct braking systems: the primary braking system, a secondary safety system that takes over in case of a fault, and an emergency braking system for critical situations. This technological redundancy demonstrates how essential flawless braking performance is for your safety and for others on the road.

Hydraulic brake circuit problems

Brake hose deterioration

Brake hoses are the arteries of the hydraulic system and are susceptible to several types of failures. Rubber hoses can crack due to aging, exposure to extreme temperatures, or contact with aggressive chemicals. Leaks can be observed by a drop in brake fluid level in the reservoir or by fluid stains under the vehicle.

Hoses can also be pinched or kinked after improper repairs or interference with other suspension components. This situation can reduce hydraulic pressure and, consequently, braking efficiency.

Corrosion of metal brake lines

Metal brake lines, while more durable than flexible hoses, are vulnerable to corrosion, especially in wet climates or where road salt is used in winter. Rust can perforate the wall of the line, leading to fluid loss and compromising system safety.

Mechanical component failures

Problems with calipers and wheel cylinders

Brake calipers (on disc systems) and wheel cylinders (on drum systems) can develop leaks at their seals. These leaks manifest as brake fluid on nearby components or a sensation of a “soft pedal” during braking.

Piston failure in the calipers can cause uneven braking, which translates to the car pulling to one side during braking or uneven wear of the brake pads.

Uneven wear of brake pads

Brake pads can show uneven wear for several reasons. A piston stuck in the caliper will cause constant pressing of one pad, leading to accelerated wear of that pad and rotor overheating. Also, corroded pad guides can prevent free movement, resulting in constant contact with the rotor.

Brake master cylinder failures

The master brake pump (master cylinder) is the heart of the hydraulic system. When the brake pedal can be pressed to the floor without significant resistance, this usually indicates a serious problem with the brake pump. The cause can be a defective seal inside the pump or a major fluid loss in the system.

A faulty brake pump can allow air to enter the circuit, significantly compromising braking efficiency and potentially creating dangerous situations.

Brake discs problems

Cracking of brake discs

Repeated overheating of the discs can cause radial cracks. These cracks usually start at the outer edge and propagate inward. A cracked disc presents a major risk of complete breakage during braking.

Uneven wear

Uneven wear of the discs manifests as warping or “humming” felt in the steering wheel during braking. This problem arises from local overheating, uneven pad wear, or suspension problems.

Secondary component failures

Wheel bearing problems

Although not directly part of the braking system, wheel bearings can be affected by sudden braking, repeated heavy braking, or strong impacts with potholes while braking. A faulty bearing will generate noise and vibrations, potentially affecting vehicle control.

ABS sensor faults

The wheel speed sensor is essential for the function of ABS. Contamination with dirt, oil, or physical damage can cause improper operation of the anti-lock braking system. Symptoms include the ABS warning light coming on the dashboard.

Warning signs and preventive measures

Early recognition of braking system issues can prevent serious accidents. Watch for:

- Unusual noises during braking (squealing, metal grinding)

- Vibrations in the brake pedal or steering wheel

- Increased stopping distance

- A soft brake pedal that sinks toward the floor

- The car pulling to one side when braking

- Brake fluid level dropping

- A smell of burning brakes after heavy driving

Regular brake system inspections, including a visual check of brake discs and fluid level, can prevent many of these issues. Preventive maintenance is cheaper and safer than emergency repairs.

Photo source: liveabout.com, halfords.com